Understanding Aminoethylpiperazine Epoxy

This comprehensive guide delves into the world of aminoethylpiperazine epoxy, a versatile compound used across various industrial applications. Known for its unique properties that enhance epoxy resins, it serves crucial roles in product manufacturing and industrial processes. This article outlines its structure, benefits, usage, and industry-relevant insights, offering valuable information for professionals and enthusiasts alike.

Introduction to Aminoethylpiperazine Epoxy

Aminoethylpiperazine epoxy is a specialized compound that plays an integral role in advanced industrial applications, especially within the field of epoxy resins. This compound is celebrated for its effectiveness in enhancing the mechanical and chemical properties of epoxies, making it indispensable in industries such as construction, automotive, and electronics. The recent growth in infrastructure development and technological advancements has further propelled the demand for high-performance materials like aminoethylpiperazine epoxy. As such, an in-depth understanding of its features, production processes, and applications can serve industries that utilize resin technologies.

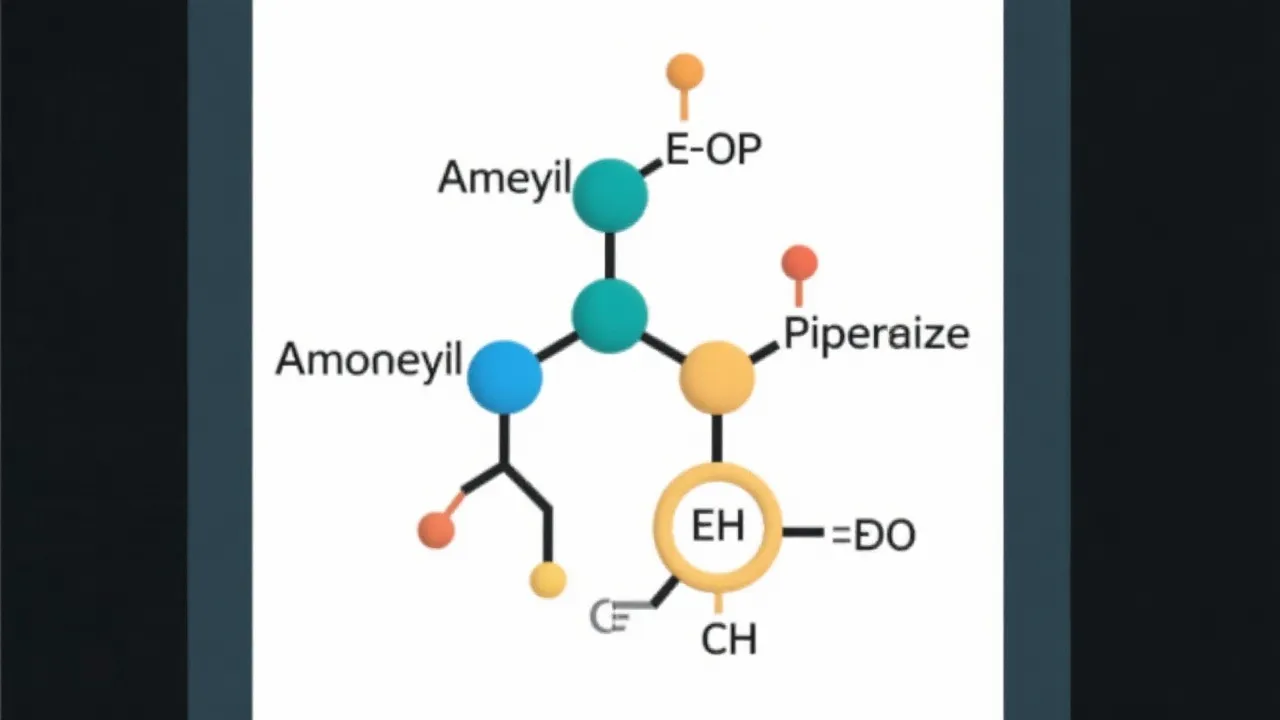

The Chemical Structure and Properties

Aminoethylpiperazine epoxy integrates the amine-rich characteristics of aminoethylpiperazine with the robust structural characteristics of epoxy resins. This chemical amalgamation results in a compound that offers exceptional adhesion, durability, and chemical resistance. The presence of multiple functional amine groups facilitates cross-linking with epoxy groups, significantly improving the final product's thermal stability and performance. Furthermore, aminoethylpiperazine's molecular structure allows it to provide superior flexibility, making it ideal for applications that require not only strength but also elasticity. Such properties are particularly useful in dynamic environments where materials might undergo stress and strain.

Applications in Industry

One of the prominent applications of aminoethylpiperazine epoxy lies in coatings and adhesives, where its high-performance attributes are crucial. In the construction sector, it provides strong, weather-resistant coatings that extend the lifespan of structures. In the automotive industry, it helps create components that can withstand harsh environments, thus enhancing vehicle durability. Its applications extend to the electronics field as well, being used in encapsulating electronic components to provide protection against moisture and corrosion. With increasing concerns around material longevity and environmental performance, the versatility of aminoethylpiperazine epoxy is becoming more acknowledged across various industries.

Case Study: Coatings and Adhesives

The compound's potent adhesive properties are invaluable in producing high-performance coatings. This has been particularly beneficial in mitigating corrosion in metal substrates, thereby enhancing the durability and maintenance lifespan of infrastructures and machinery. A notable implementation occurred in a major bridge renovation project where aminoethylpiperazine epoxy coatings were applied to both protect metal from corrosion and improve bonding between structural elements. The project's success led to increased adoption of this epoxy compound in similar infrastructure applications, demonstrating its effectiveness in real-world scenarios where durability and longevity are paramount.

Benefits in Manufacturing

- Enhanced Durability: Provides superior wear resistance for industrial products, significantly surpassing traditional materials in extreme operating conditions.

- Environmental Resistance: Improves resistance to environmental factors, including humidity, UV radiation, and chemical exposure, which is critical for outdoor and industrial environments.

- Improved Adhesion: Enhances the adhesive strength across various surfaces, allowing for the bonding of diverse materials such as plastics, metals, and composites.

- Thermal Stability: Extends applicability in high-temperature environments, making it suitable for applications ranging from automotive components to aerospace engineering.

Comparative Analysis of Epoxy Compounds

| Property | Aminoethylpiperazine Epoxy | Standard Epoxy |

|---|---|---|

| Adhesion | High | Medium |

| Durability | High | Standard |

| Chemical Resistance | Outstanding | Moderate |

| Thermal Stability | Superior | Good |

| Flexibility | Excellent | Rigid |

This comparative analysis reveals that aminoethylpiperazine epoxy consistently outperforms standard epoxies across numerous critical properties, including adhesion and flexibility. By providing these enhanced characteristics, it broadens the scope of potential applications where traditional epoxies might fail. Industries are leaning towards this advanced epoxy solution to ensure their products are resilient against wear and damage.

FAQs

Q1: What makes aminoethylpiperazine epoxy more efficient than standard epoxies?

A1: The integration of amine groups in aminoethylpiperazine epoxy enhances cross-linking, improving adhesion, durability, and thermal stability compared to standard epoxies. These factors contribute to longevity and better performance in demanding environments.

Q2: What industries benefit the most from using this compound?

A2: Industries such as construction, automotive, marine, and electronics significantly benefit due to the compound's excellent resistance to harsh conditions and durable properties. For instance, marine applications utilize the waterproof nature of the epoxy to protect boats and ships from corrosive saltwater.

Q3: How does it improve the sustainability of industrial processes?

A3: The enhanced durability and performance of products reduce the need for frequent replacements, thereby contributing to more sustainable industrial practices. In addition, less frequent maintenance translates to lower resource consumption and reduced waste production over time.

Emerging Trends in the Use of Aminoethylpiperazine Epoxy

As technology progresses, the landscape of epoxy applications is also evolving. Aminoethylpiperazine epoxy is increasingly being recognized not only for its strength and durability but also for its potential as a sustainable material in a world that is shifting towards eco-friendliness. The demand for green materials in manufacturing processes is leading to innovations where manufacturers are exploring bio-based formulations of aminoethylpiperazine, which would reduce reliance on petrochemical resources. Furthermore, developments in nanotechnology are paving the way for integrating nano-fillers with aminoethylpiperazine epoxy to enhance its mechanical properties and further broaden its applications.

Nanotechnology Applications

Integrating nanotechnology with aminoethylpiperazine epoxy is opening new avenues of exploration. Research indicates that incorporating nano-fillers like silica, carbon nanotubes, or clay improves the mechanical, thermal, and electrical properties of the epoxy resin mixture. These advancements may lead to the production of lighter and more robust materials suitable for aerospace applications, thereby pushing the boundaries of what epoxy composites can achieve. Innovations in this area will likely yield products that not only meet the increasing demands of various industries but also align with sustainability goals through enhanced efficiency and lower material usage.

Future Directions

The future of aminoethylpiperazine epoxy is poised for growth as industries seek more robust solutions to complex engineering challenges. With ongoing research into new formulations and composites, the potential applications for aminoethylpiperazine epoxy are expanding. The focus on sustainability is influencing the development of lower-emission production techniques, which will create a more eco-friendly footprint for these resins. Additionally, collaborations between material scientists and engineering teams are essential for developing cutting-edge products that meet stringent performance criteria.

Smart Materials Integration

One exciting prospect for aminoethylpiperazine epoxy involves its integration into smart materials that could change its properties in response to environmental stimuli. For instance, the incorporation of sensors into the epoxy matrix could enable it to monitor structural integrity and alert engineers to potential failures before they occur. As industries move towards predictive maintenance and enhanced monitoring systems, the pairing of aminoethylpiperazine epoxy with smart technology could lead to significant advancements in safety and proactive material management.

Conclusion

Aminoethylpiperazine epoxy offers significant advantages over traditional epoxy formulations, making it a cornerstone in modern manufacturing applications. Its unique combination of properties translates into superior industrial products that meet the demanding standards of various sectors, promising continued relevance and application in future technological advancements. As the focus on sustainability gains momentum, the adaptation of aminoethylpiperazine epoxy into green chemistry principles may bolster its leadership in eco-friendlier industrial materials. It is imperative for industries to keep abreast of these trends and developments to fully leverage the potential benefits of aminoethylpiperazine epoxy in enhancing product performance and sustainability.