Understanding the Caterpillar Injector System

The Caterpillar Injector is a crucial component in heavy machinery and industrial applications, fundamental in driving performance and efficiency. Engineered for precision, these injectors play an essential role in maintaining optimal fuel delivery, ensuring robust operation under varied conditions. Their design evolution and technological advancements are pivotal in meeting current environmental and operational standards.

An In-Depth Look at Caterpillar Injector Systems

The Caterpillar Injector system represents a key innovation in the field of heavy machinery, driving efficiency and reliability. These injectors are meticulously designed for precision fuel delivery into the engine’s combustion chamber, ensuring optimal performance and compliance with emissions standards. In a world increasingly focused on sustainability and performance, Caterpillar's cutting-edge technology stands out as a paramount solution for various industrial applications.

Caterpillar injectors are known for their durability and ability to withstand the harsh conditions often encountered in industries such as construction, mining, and logistics. These industries demand machinery that can endure extreme environments—both thermal and mechanical—while delivering consistent and reliable performance. By implementing state-of-the-art technology, these injectors minimize fuel wastage, thereby not only boosting performance but also reducing environmental impact through lower emissions.

On top of their innovative engineering, Caterpillar continually invests in research and development to enhance their injector systems, making them a leading choice among heavy equipment manufacturers and operators globally.

The Importance of Fuel Injection Technology

Modern fuel injection technology has dramatically changed the landscape of engine operations. Unlike carburetion, which relies on air pressure to draw fuel into the engine, fuel injection uses finely tuned pistons to precisely measure and deliver fuel. This precision results in better fuel economy and decreased emissions, crucial aspects in today’s environmentally-conscious market. Furthermore, fuel injection systems improve cold starting performance, throttle response, and overall drivability by delivering the exact amount of fuel required under varying conditions.

Understanding how fuel injection technology works can provide insights into why modern engines are designed the way they are. Since fuel is injected directly into the combustion chamber rather than premixed with air beforehand, this location-specific delivery allows for better mixing and combustion efficiency, improving power output while minimizing unburned fuel and harmful emissions. Such advantages are particularly beneficial for businesses looking to optimize operational costs and environmental compliance.

Advancements in Caterpillar Injector Technology

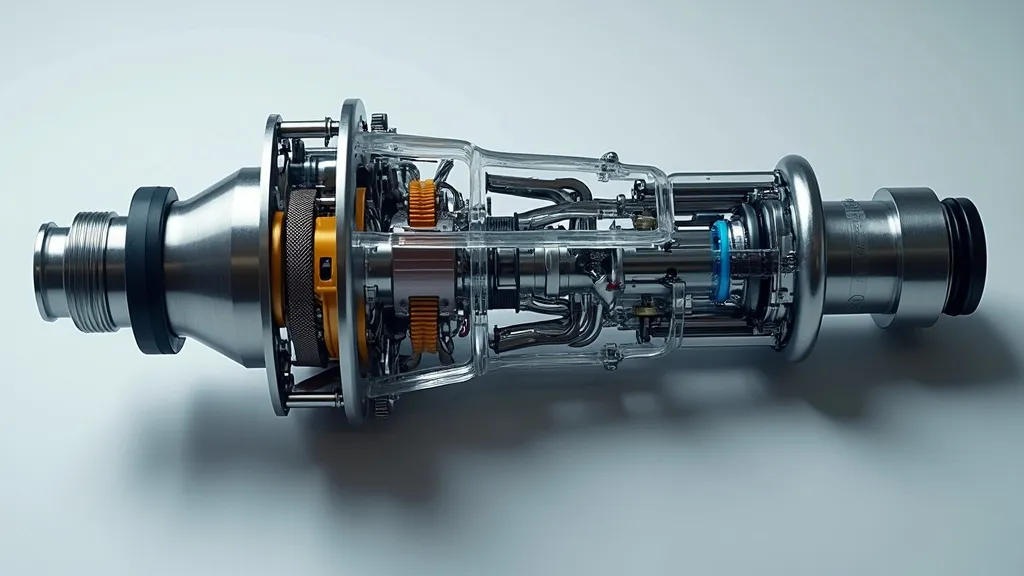

The evolution of the Caterpillar injector system can be attributed to advancements in materials science and fluid dynamics. These systems incorporate high-strength alloys and advanced seals that prevent leakage and withstand high pressure and temperature. This robustness ensures that machinery operates efficiently without frequent downtimes, translating to better productivity for industries reliant on heavy machinery.

Moreover, the use of computer-aided design (CAD) and computational fluid dynamics (CFD) in the development of Caterpillar injectors has enabled engineers to simulate and analyze the flow of fuel through these injectors under various conditions. This level of analysis facilitates improvements in injector design, ensuring that they meet or surpass the demanding specifications required for modern engines.

One significant advancement in the technology of Caterpillar injectors is the integration of electronic controls that optimize fuel delivery based on real-time conditions. By adjusting injection timing and duration, these systems respond dynamically to load changes, allowing engines to operate at peak efficiency. With such innovations, there is an incredible reduction in emissions and an incremental improvement in overall fuel economy.

Upgrading and Maintenance

Regular maintenance is vital to ensure the longevity and optimal performance of Caterpillar injectors. A well-maintained injector system can yield substantial returns on investment through decreased fuel costs and improved operational efficiency. By adhering to a strict maintenance schedule, operators can identify wear and tear early on, addressing issues before they evolve into more significant problems that could hinder the performance of heavy machinery.

Upgrading old injector systems with the latest models can drastically enhance an engine’s fuel efficiency and reduce operational costs. Moreover, older machinery may not incorporate the latest emissions-reducing technologies, making upgrades essential not just for performance but for compliance with environmental standards. Caterpillar offers various injector solutions that can fit a wide array of engine models, ensuring compatibility and reliability.

Common maintenance tasks include inspecting fuel filters and lines for clogs or leaks, cleaning injector nozzles to prevent buildup, and checking electrical connections on electronically controlled injectors. Scheduling such maintenance can prevent fuel delivery issues that lead to poor engine performance. Additionally, Operators should also maintain proper records of maintenance and injector replacements to optimize machinery performance and longevity.

Benefits of Using Caterpillar Injectors

- Enhanced durability and reliability in extreme conditions.

- Reduced fuel consumption, contributing to lower operational costs.

- Improved engine performance through optimal fuel delivery.

- Compliance with stringent environmental regulations, which is increasingly important in many regions around the globe.

- Advanced features like electronic controls, enhancing adaptability and efficiency.

- Reduction in maintenance time and costs due to superior design and technology.

FAQs

- What makes Caterpillar injectors different from other brands?

Caterpillar injectors boast exceptional precision and durability, designed to meet the rigorous demands of industrial applications. They are engineered to work seamlessly within the Caterpillar ecosystem of heavy machinery, ensuring that every component works harmoniously for optimal performance. - How often should Caterpillar injectors be replaced?

They should be inspected regularly and replaced as needed, generally every 100,000 miles or as specified by the manufacturer. Factors such as the working environment, type of fuel used, and engine maintenance history can influence the interval for replacement. - Can I upgrade my current machinery with newer Caterpillar injectors?

Yes, upgrading to modern injectors can enhance performance and fuel efficiency. This upgrade can lead to improved reliability, reduced emissions, and potential cost savings over time. However, verifying compatibility with your current machinery before making any upgrades is crucial. - What are the symptoms of a failing injector?

Poor engine performance, increased emissions, and reduced fuel efficiency are common indicators. Other symptoms might include engine misfires, rough idling, and excessive smoke from the exhaust. Identifying these symptoms early can help prevent more extensive damage to the engine.

The Future of Caterpillar Injectors

As technology progresses, the role of the Caterpillar injector will continue to evolve, paving the way for even more efficient machinery and sustainable practices in industrial settings. The integration of digital technologies such as the Internet of Things (IoT) into heavy machinery has opened new avenues for monitoring and optimizing performance metrics in real-time.

Advancements in telemetry enable engineers and operators to gather data on fuel efficiency, injector performance, and overall engine health. This data can be analyzed to inform predictive maintenance strategies, potentially reducing downtime and repair costs even further.

Moreover, as regulatory environments become more stringent globally, the development of injectors that meet emerging emissions regulations will focus on cleaner burning technologies. Caterpillar is dedicated to pioneering innovations in fuel injector technology that align with their environmental commitments. This commitment ensures that equipment users can meet their productivity demands while adhering to increasingly complex legal frameworks focused on sustainability.

Caterpillar's Commitment to Sustainability

Sustainability remains a core value for Caterpillar. By enhancing fuel efficiency with advanced injector systems and reducing overall emissions, the company not only helps its customers but also contributes to a greener planet. Caterpillar is continually researching eco-friendly fuel alternatives and developing injectors compatible with future fuels, including biofuels and hydrogen.

This commitment extends beyond just the fuel injectors themselves; it permeates the entire design and manufacturing process. Efforts are made to minimize waste and recycle materials throughout the product lifecycle. Caterpillar's sustainability initiatives resonate with clients seeking to uphold their environmental responsibility while maximizing efficiency and productivity.

Customer Support and Training

Caterpillar provides extensive support and training resources for customers to ensure they get the most out of their injector systems. Many authorized dealers offer seminars and workshops that educate operators about best practices for maintaining injectors and optimizing their performance. This level of engagement helps ensure that machinery owners are not only informed about the technology they are using but also equipped with the knowledge needed to identify issues early and mitigate potential down-time.

In addition to in-person training, Caterpillar has also embraced digital transformation by offering online resources, including instructional videos, manuals, and technical support. This multi-faceted approach ensures that every user has access to the tools needed for effective maintenance and troubleshooting, allowing them to reap the full benefits of their investment in Caterpillar machinery.

Conclusion

In conclusion, Caterpillar Injector systems represent a critical component in the functionality and efficiency of modern heavy machinery. Their advanced design and engineering provide unparalleled performance, making them essential for industries demanding reliability and efficiency. Through constant innovation, rigorous maintenance practices, and a commitment to sustainability, Caterpillar ensures that its injectors not only meet but exceed the expectations of operators worldwide.

With ongoing developments in fuel technology and a focus on environmental stewardship, the future of Caterpillar injectors holds promise for further reducing operational costs and environmental impact while enhancing the capabilities of today’s machinery. As industries evolve, so will the technology behind these injectors, allowing Caterpillar to lead the way in innovative solutions that meet the needs of a demanding market.