Understanding Caterpillar Injector Systems

Caterpillar injectors are pivotal components in the robust engineering of heavy-duty machinery, renowned for their efficiency and reliability. These injectors facilitate precise fuel delivery, crucial for machinery performance and emissions control. This article explores their function, maintenance, and impact on performance.

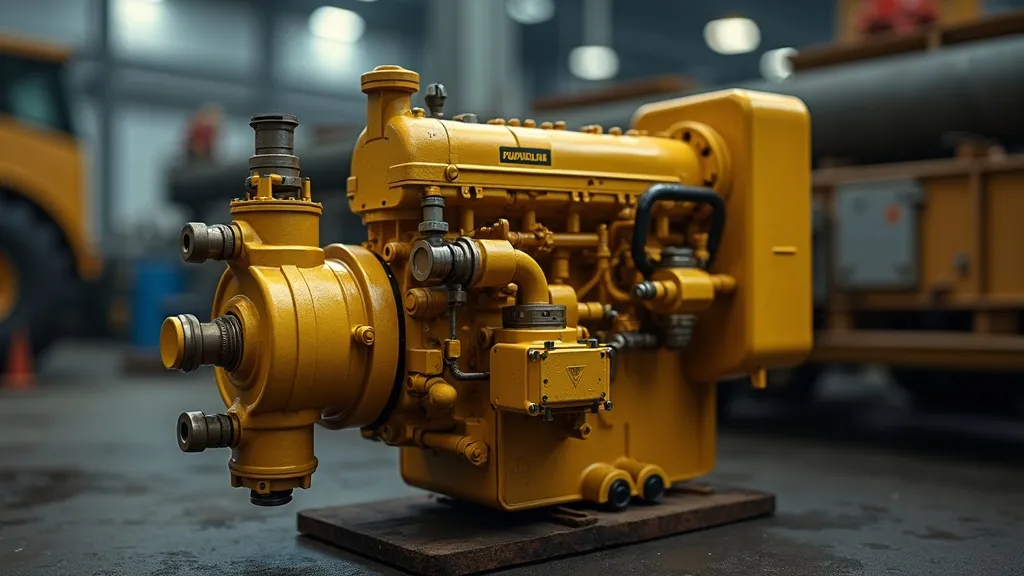

Introduction to Caterpillar Injector Systems

Caterpillar injectors play a crucial role in the functioning of industrial and construction machinery. Designed to ensure optimal combustion and fuel efficiency, these injectors are integral to the operation of engines in bulldozers, excavators, and various other heavy-duty machines. As machines continuously strive against the rigors of tough environments and demanding loads, the reliability and efficiency of injectors are paramount. They not only affect operational costs but also influence overall productivity, making them a vital component in the fleet management of any construction or industrial application.

The Role and Importance of Injectors

Injectors are devices designed to introduce fuel into the combustion chamber of an engine. In the realm of Caterpillar machinery, the injector is quintessential for maintaining efficiency. By precisely controlling the amount and timing of fuel injection, these components help minimize excess fuel use and reduce emissions, contributing to both cost savings and environmental compliance. Beyond just fuel delivery, injectors also crucially influence engine performance characteristics including power output, throttle response, and operational smoothness. Properly functioning injectors contribute significantly to the longevity of the engine as well, as they ensure that fuel is atomized correctly for optimal combustion.

Structure and Functionality

The operational efficiency of Caterpillar injectors lies in their sophisticated engineering. Typically made from durable materials such as high-grade steel, these injectors can withstand high pressure and temperature. The precision engineering ensures that each injector delivers a specific amount of fuel at the exact right moment, crucial for the optimal functioning of Caterpillar engines. The unit typically comprises multiple components, including the nozzle, the solenoid, and the spring. Each of these parts must work in harmony; for example, the solenoid needs to respond quickly to electrical signals to open and close the injector rapidly, thereby allowing accurate control over how much fuel is injected. The nozzle design itself is critical as well – it is engineered to create a fine mist of fuel that promotes better mixing with air for complete combustion. Caterpillar’s commitment to precision means that even slight deviations in injector performance can have a notable impact on both efficiency and durability.

Maintenance and Troubleshooting

To ensure longevity and performance, regular maintenance of Caterpillar injectors is vital. Common signs of injector problems include engine misfires, reduced fuel efficiency, and increased emissions. Regular diagnostic checks can help identify issues early. Factors that may lead to injector failure include dirty fuel, deposits from incomplete combustion, and wear from vibration and thermal stress. Professional tuning and cleaning can often resolve these problems, restoring the injector's performance. In certain cases, fuel filters should be changed regularly to prevent debris from clogging injectors. Additionally, fuel quality is of utmost importance; using high-quality fuel can help reduce the likelihood of carbon deposits forming on injector nozzles, which can significantly impair performance. This meticulous approach to maintenance extends the life of the injectors, minimizing downtime and maintenance costs for operators.

Impact on Fuel Economy and Performance

Properly functioning injectors are pivotal in optimizing the fuel economy of Caterpillar machinery. With precise fuel delivery, machinery operates efficiently, conserving fuel and reducing costs. Moreover, the improved combustion resulting from high-quality injectors enhances overall machine performance, offering a balance of power and efficiency. Research has shown that the correct functioning of injectors can lead to up to a 5% improvement in fuel economy, which can translate to considerable savings over time, especially for operators of fleets. This increased fuel efficiency not only benefits the bottom line directly but contributes indirectly to the environment by reducing emissions from fossil fuels. Lesser emissions lead to better compliance with environmental regulations, reducing the risk of penalties and improving public image in an era where companies face growing scrutiny over their sustainability practices.

Comparison Table of Injector Specifications

| Model | Operating Pressure (bar) | Flow Rate (cc/min) | Typical Applications | Recommended Maintenance Schedule (hours) |

|---|---|---|---|---|

| Cat Series 320 | 1800 | 70 | Excavators, Bulldozers | 250-500 |

| Cat Series 340 | 2200 | 95 | Loaders, Scrapers | 250-500 |

| Cat Series 370 | 2600 | 110 | Backhoe Loaders, Heavy Trucks | 250-500 |

Understanding Common Injector Issues

Understanding fuel injectors also involves recognizing potential issues that can arise, and their implications for machine performance and fuel economy. Some of the common injector issues include:

- Clogged or Dirty Injectors: Over time, injectors can become clogged due to deposits from fuel or changes in the fuel’s viscosity. This can lead to inconsistent fuel delivery, engine knocking, or poor fuel atomization.

- Leaking Injectors: If an injector is leaking, it can create a hazardous situation resulting in engine flooding, poor performance, and increased emissions. Regular checks can identify leaks before they escalate into significant issues.

- Electrical Failures: The solenoid that controls injector operation may fail due to electrical surges or corrosion, leading to improper fuel injection timing. Diagnostics that check electrical systems are crucial to identifying these failures.

- Poor Fuel Quality: Low-quality fuel can lead to quicker deposits accumulating in injectors, thereby reducing their efficiency over time. Ensuring fuel quality from trusted suppliers can mitigate this issue significantly.

FAQs on Caterpillar Injectors

- How often should Caterpillar injectors be inspected?

Regular inspections every 250-500 hours of operation are advised for optimal performance. It is also wise to inspect injectors when performing other maintenance tasks, such as oil changes. - What is the impact of a faulty injector?

A malfunctioning injector can lead to decreased fuel efficiency, higher emissions, and potential engine damage. If unnoticed, the wear and tear can necessitate expensive repairs or even engine replacement. - How can injector problems be detected early?

Regular diagnostic tests and monitoring of engine performance indicators can help identify issues early. Listen for unusual sounds from the engine, observe vibrations, and track fuel consumption rates for signs of injector issues. - What are common symptoms of injector failure?

Some common symptoms include rough idling, poor acceleration, increases in exhaust smoke, and a check engine light triggering on the dashboard. - How do temperature fluctuations affect injectors?

Extremes in temperature can affect the viscosity of fuel, potentially leading to injector issues. Operators should ensure that injector systems are well-protected against high heat environments when machines are exposed to direct sunlight or high operating temperatures.

Conclusion

Understanding the pivotal role of Caterpillar injectors in machinery highlights their importance in maintaining efficiency and performance. Regular maintenance and precise diagnostics are essential for prolonging their operational life and optimizing their performance. By doing so, operators can ensure machinery remains cost-effective and environmentally friendly, continuing to meet the demands of heavy industries. A comprehensive understanding of how injectors operate, their common issues, and maintenance best practices not only contributes to effective fleet management but also enhances the safety and reliability of operations in demanding job sites. Such insight arms equipment operators and fleet managers with the tools they need to maximize their investments while navigating the complexities of machinery maintenance in an ever-evolving landscape of industrial performance.

Additional Insights into Injector Technology

As technology progresses, so too does the innovation that fuels Caterpillar injectors. New advancements in injector technology promise to enhance overall performance while ensuring compliance with increasingly strict emissions regulations. For example, the adoption of advanced fuel injection systems such as common rail direct fuel injection, variable geometry turbochargers, and electronic control units enables more precise fuel management than older mechanical systems. These innovations allow for variable timing and volume of fuel delivery, optimizing combustion under various operating conditions and significantly improving fuel economy.

The Future of Fuel Injectors in Heavy Machinery

Looking ahead, the future of fuel injectors will likely continue to evolve along with advancements in alternative fuels and renewable energy sources. Caterpillar, like many major manufacturers, is investing in research and development to produce injectors that can accommodate biofuels and hydrogen fuel systems. These initiatives reflect a broader industry trend towards sustainability and the reduction of dependence on traditional fossil fuels. Heavy machinery equipped with advanced injector systems will not only be more efficient but will also play a crucial role in meeting global sustainability goals.

Case Studies on Injector Performance

Real-world applications can offer valuable insights into how injectors impact performance and operational efficiency. For example, a major construction company in the Midwest upgraded its fleet of excavators with new Caterpillar injectors that employ common rail technology. The results showed a dramatic 10% increase in fuel efficiency over the previous injector models and significantly reduced emissions, enabling the company to meet contract specifications for low environmental impact. Regular maintenance schedules combined with the new injector technology resulted in less downtime and greater operational readiness on job sites.

Conclusion on Injector Advancement

By harnessing advanced injector technology, operators can maximize the longevity and performance of their heavy machinery. The investment in high-quality injectors not only pays off in the form of enhanced efficiency but also reduces the overall cost of ownership by decreasing the frequency and severity of maintenance needs. As the industry changes and adapts to new environmental challenges, staying informed about injector technology will empower operators to make the best decisions to achieve operational excellence and sustainability.