Understanding PKZ Connectors

PKZ connectors are pivotal in forming reliable and efficient connections in a wide array of electrical applications. These connectors are engineered to provide secure and stable connections that ensure optimal performance. Understanding their functionality, design, and applications can yield significant benefits in both industrial and domestic settings.

Introduction to PKZ Connectors

In today's technologically driven world, the small yet crucial components like PKZ connectors play an essential role in ensuring seamless operations across various electrical systems. These connectors are characterized by their reliability and efficiency, making them indispensable in both industrial and domestic applications. Their presence enhances performance and safety, contributing significantly to the overall functionality of the devices they are integrated into.

What Are PKZ Connectors?

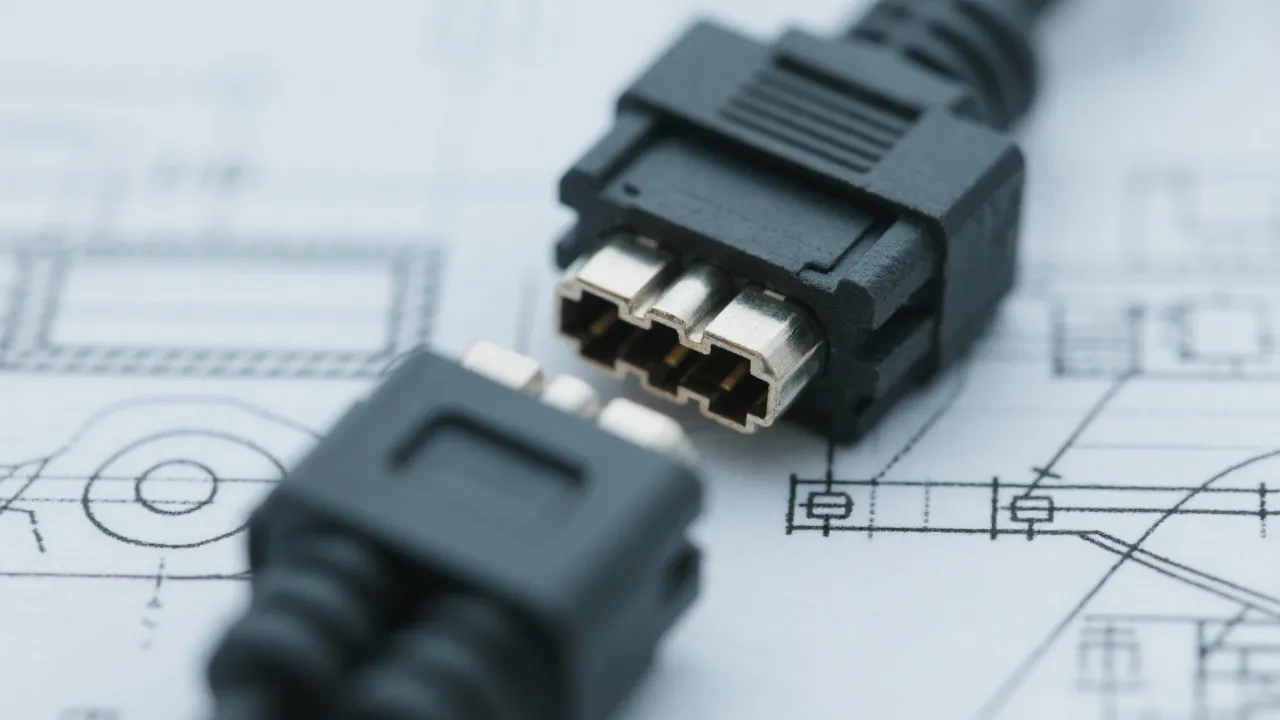

PKZ connectors are specialized devices designed to establish strong electrical connections in a wide range of equipment and machinery. These components are engineered to withstand different environmental conditions and mechanical stresses, ensuring the integrity of the connection. Made from high-quality materials, PKZ connectors can endure harsh conditions, which is why they are often chosen for applications ranging from simple domestic electronics to complex industrial machinery. Some typical materials used in their construction include durable plastics and metals that can withstand corrosion and wear.

Features and Benefits

- Durability: PKZ connectors are built using high-quality materials that resist wear and tear, providing longevity. This durability extends not only the lifespan of the connectors themselves but also contributes to the overall reliability of the systems they are part of.

- Versatility: These connectors come in various sizes and configurations, making them suitable for diverse applications. Whether it's in automotive systems, aerospace engineering, or household appliances, PKZ connectors offer solutions tailored to specific needs.

- Easy Installation: Designed for user-friendly scns, PKZ connectors can be easily installed, reducing downtime. This ease of installation accelerates manufacturing processes and enhances productivity, which is vital in both industrial and consumer markets.

- Reliable Connections: They ensure stable and efficient electrical connections, minimizing the risk of disruption. This reliability not only enhances system performance but also increases safety by reducing the chances of electrical failures that could lead to hazards.

Applications of PKZ Connectors

PKZ connectors are versatile and find applications across multiple domains. Here are a few key areas where they are widely used:

- Automotive Industry: Essential in designing modern vehicles, these connectors ensure reliable connections in electrical systems, facilitating functions such as lighting, infotainment, and engine management systems. Their reliability is critical given the increased complexity and the demanding environments found in today’s vehicles.

- Consumer Electronics: PKZ connectors are often used in everyday devices, from home appliances to personal gadgets. Their role is vital in ensuring that devices operate smoothly and safely, enhancing the user experience.

- Networking and Telecommunications: They play a significant role in maintaining stable connections in communications infrastructure, which is essential for data transfer and communication, especially in an era where connectivity is paramount.

- Industrial Machinery: In robust industrial settings, they ensure the efficient operation of heavy machinery. Their capacity to tolerate extreme conditions is crucial for industries such as manufacturing, where operational efficiency is linked directly to the reliability of connections.

Design Considerations

When selecting PKZ connectors for a specific application, several factors need to be considered to ensure optimal performance. It's crucial to understand the electrical, mechanical, and environmental requirements of the application, including factors like current rating, voltage, connection type, and environmental conditions such as temperature and exposure to chemicals. For example, applications in outdoor settings demand connectors that can withstand water exposure and UV radiation, while those used in manufacturing might require resistance to dust and mechanical vibrations.

Moreover, it is important to consider the dimensions and form factor of the connectors, ensuring they fit within the designated space of the equipment they will be used in. A compact design is often favored in consumer electronics to maintain aesthetics and functionality without compromising on performance. Additionally, regulatory and safety standards may influence the choice of connectors, especially in industries such as automotive and medical sectors where compliance is mandatory.

Comparison Table: PKZ Connectors vs Traditional Connectors

| Feature | PKZ Connectors | Traditional Connectors |

|---|---|---|

| Durability | Highly durable with extended lifespan | Varies, often less durable |

| Installation | Designed for ease of installation | May require specialized tools |

| Flexibility | Wide range of applications | Limited to specific uses |

| Cost-Effectiveness | Good savings due to durability | Potentially higher maintenance costs |

| Connection Quality | High-quality connections that minimize signal loss | Variability in connection quality, depending on the design |

| Maintenance | Low maintenance requirements | May require regular checks and maintenance |

FAQs

Q1: Can PKZ connectors be used in outdoor applications?

Yes, PKZ connectors are often designed to withstand harsh environmental conditions, making them suitable for outdoor applications. Their resistance to temperature changes, moisture, and UV radiation is a significant factor that enhances their usability in such settings.

Q2: Are there specific tools required for installing PKZ connectors?

Most PKZ connectors are designed for easy installation and do not require specialized tools, though it may depend on the particular model and application. However, some complex installations may demand basic tools like screwdrivers or crimping tools for secure connections.

Q3: How do PKZ connectors improve system reliability?

By providing stable and secure connections, PKZ connectors minimize connection failures, thus enhancing system reliability. This reduction in failure rates not only leads to more efficient performance but also prolongs the lifespan of both the connectors and the overall system.

Q4: Do PKZ connectors pose any safety risks?

When installed correctly, PKZ connectors are designed to meet safety standards that minimize electrical hazards. It is crucial, however, to ensure that the connectors are appropriate for the specific application to avoid overheating and potential short circuits.

Q5: How can I determine the right PKZ connector for my project?

To determine the right PKZ connector for your project, consider the specific electrical parameters such as voltage and current requirements, the environment in which the connector will operate, the physical form factor required for your application, and any compliance or certification standards needed.

Conclusion

PKZ connectors represent a vital element in the architecture of modern electrical systems. With their adaptability, reliability, and ease of use, these connectors are a preferred choice across various sectors, ensuring that both industrial and personal devices function seamlessly and effectively. As technology continues to evolve, the demand for high-performance connectors like PKZ will likely increase, driving innovations in design and application. Whether for automotive, industrial, or consumer electronics, understanding the value and applications of PKZ connectors is essential for engineers, designers, and technicians working in these fields.

The Future of PKZ Connectors

The future of PKZ connectors looks promising as technology continues to advance. Innovations in materials and manufacturing processes will enhance their functionality and performance. As industries grow more dependent on automation and interconnected systems, the demand for reliable electrical connections increases.

One significant trend is the push towards miniaturization in electronics. Devices are becoming smaller and more compact, necessitating connectors that are not only durable but also space-efficient. Manufacturers of PKZ connectors are likely to focus on developing smaller connectors without sacrificing performance. This trend will require advancements in design, ensuring that even the smallest connectors can handle high power and data rates without compromising safety.

Additionally, as the focus on sustainability increases globally, there may be a shift towards producing PKZ connectors from environmentally friendly materials. Innovations in biodegradable plastics or recycled metals could play a role in this development, aligning with green technology initiatives and helping industries reduce their carbon footprint.

Advancements in Technology

As technology advances, there will be a significant emphasis on smart connectors. These connectors could integrate sensors that monitor electrical performance, providing real-time feedback on connection stability and potential failures. Implementing smart technology within PKZ connectors would enhance their reliability further and allow manufacturers and users to maintain systems more effectively, identifying issues before they escalate into costly problems.

Integrating PKZ Connectors in Smart Systems

In line with the rise of smart technologies and the Internet of Things (IoT), PKZ connectors are expected to play a crucial role in integrating various devices and systems. The ability to have reliable connections across multiple devices is essential for smart systems to function seamlessly. Smart homes, industrial automation, and connected vehicles all require high-quality connectors to ensure data is transmitted accurately and efficiently.

Moreover, the implementation of advanced materials in PKZ connectors, like high-grade thermoplastics and specialized coatings, can further reduce wear and tear, which is invaluable in environments where connectors are frequently plugged and unplugged. This advancement can be especially beneficial in industries like telecommunications and automotive, where connectors are subjected to extensive stress and environmental challenges.

Conclusion: The Lasting Impact of PKZ Connectors

In conclusion, PKZ connectors are more than just a technical component; they are a vital part of the modern electrical landscape. From enabling the functionality of everyday devices to ensuring the reliability of complex industrial systems, PKZ connectors serve as a backbone in electrical engineering. The continuous evolution in their design and application reflects the dynamic nature of technological advancement. As new challenges arise in the electrical and electronic sectors, PKZ connectors will adapt and innovate, paving the way for future developments that will enhance performance and contribute to a smarter, more connected world.