Optimizing Electrical Systems with Pkz Connectors

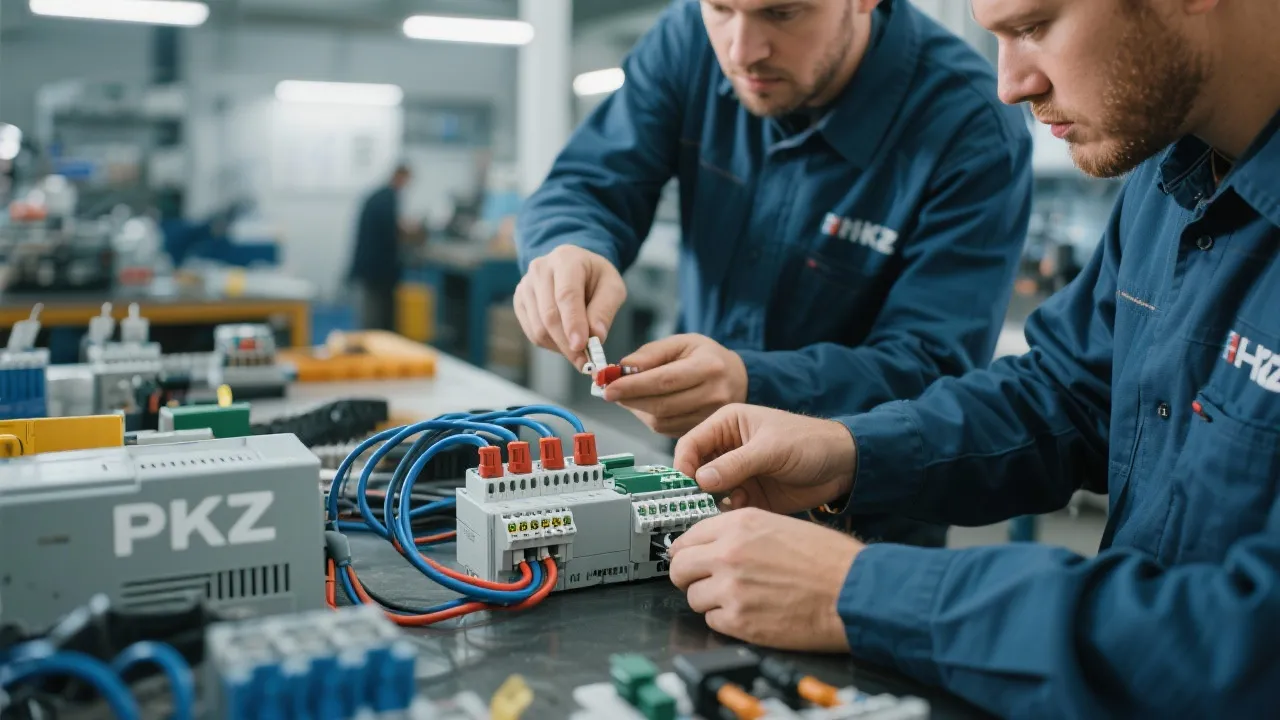

Pkz Connectors have emerged as a critical component in modern electrical systems, offering superior performance and reliability. These connectors are engineered to ensure secure connections in various applications, from industrial to residential settings. Their introduction into the electrical industry marked a shift towards more efficient and safer connections, addressing numerous challenges traditionally faced in electrical systems.

Introduction to Pkz Connectors

Pkz Connectors have revolutionized the electrical industry with their unique ability to provide effective, reliable, and secure connections across a wide range of applications. From industrial setups to residential wiring, these connectors ensure that electrical systems operate smoothly and efficiently. As electrical systems become increasingly complex, the demand for robust connectors like Pkz continues to grow. With innovations in design and technology, Pkz Connectors offer solutions that not only meet but exceed the needs of modern electrical applications.

Advantages of Pkz Connectors

Among the top features of Pkz Connectors is their durability and safety. Made from high-quality materials, they are designed to withstand extreme conditions, including high temperatures and rigorous mechanical stresses. Their precision-engineered design ensures a perfect fit, reducing the risk of disconnections that can lead to system failures or safety hazards.

Pkz Connectors also facilitate easy installation and maintenance. Their user-friendly design allows for quick and secure connections, making them an ideal choice for both professionals and DIY enthusiasts. Furthermore, they are engineered to minimize electrical losses, contributing to more energy-efficient systems. The self-locking mechanisms in these connectors provide an additional layer of security, ensuring that connections remain intact even in environments that experience vibrations or movement.

Moreover, Pkz Connectors are available in a wide variety of configurations. This versatility allows them to work seamlessly in numerous applications, accommodating different wire sizes and types. Such adaptability is crucial in today’s diverse electrical landscape, where one-size-fits-all solutions may fail. Whether in harsh industrial environments or delicate home setups, Pkz Connectors prove their worth through innovation and reliability.

Integration of Pkz Connectors in Various Environments

The versatility of Pkz Connectors makes them suitable for diverse environments. In industrial settings, for example, they are often used to connect heavy machinery and sophisticated control systems. Their robust design ensures that even in very demanding conditions, the integrity of the electrical connections is maintained. These connectors can handle significant mechanical stress while maintaining optimal conductivity and performance.

In residential areas, Pkz Connectors are commonly utilized to enhance the safety and efficiency of home electrical systems. They adapt easily to different wiring configurations, making them a practical choice for electricians working on new installations or renovating existing systems. Homeowners find peace of mind knowing that these connectors are designed to minimize the risk of electrical fires and short circuits.

Further expanding their application, Pkz Connectors are also making significant inroads in growing sectors such as renewable energy. In solar and wind power systems, where reliability and efficiency are paramount, these connectors facilitate better performance and longevity of electrical connections. The increased adoption of electric vehicles (EVs) and smart home technologies further illustrates the necessity of reliable connector systems, with Pkz Connectors paving the way for seamless integration.

Comparison of Connectors

| Connector Type | Primary Use | Key Features |

|---|---|---|

| Pkz Connectors | Universal | Durability, Safety, Easy Installation |

| Standard Screw Connectors | General | Simple Design, Cost-Effective |

| Insulation Displacement Connectors | Data Networks | Fast Installation, No Stripping Required |

| Receptacle Connectors | Various Electrical Appliances | Convenience, Versatile Connection Options |

| Terminal Block Connectors | Panel Wiring | Multiple Wiring Options, Compact Design |

Installation Guide for Pkz Connectors

Installing Pkz Connectors requires attention to detail to ensure a secure and effective connection. Below is a step-by-step guide that outlines the essential processes. Each step is critical to achieving an optimal installation, and following these guidelines will help maintain the longevity and reliability of electrical systems.

Step 1: Preparing the Wires

Begin by preparing the electrical wires. Use wire strippers to remove the insulation from the ends of the wires. It is essential to strip just the right length—exposing too much wire can lead to shorts, while too little may not make a secure connection. A length of about 1/2 inch is generally sufficient for most Pkz Connectors.

Step 2: Inserting the Wires

Insert the stripped end of the wire into the appropriate slot of the Pkz Connector. Ensure that the wire is fully seated within the connector to prevent any loose connections. For certain models, visual indicators are provided to confirm that the wire is installed correctly.

Step 3: Securing the Connection

For models that require it, use the locking mechanism to secure the wire in place. This might involve tightening a screw or pressing down a locking tab, depending on the design of the connector. Ensure that the connection is tight but be careful not to over-tighten, which could damage the wire or connector.

Step 4: Testing the Connection

Once installed, it’s crucial to test the connection before finalizing the installation. This can be done using a multimeter to check for continuity and ensure that no shorts exist within the system. This step is vital in industrial application where safety is paramount.

Step 5: Final Adjustments

After testing, make any necessary adjustments. Ensure that all connections are secure and that there is no excessive tension on any wires. Consider using cable management solutions to organize and protect wires, especially in complex installations.

Maintenance of Pkz Connectors

Regular maintenance is integral to the longevity of Pkz Connectors. Since these connectors are widely used, understanding their upkeep can prevent faults in electrical systems.

To maintain Pkz Connectors:

- Routine Inspections: Conduct periodic checks to ensure that connections remain secure and free from corrosion or wear. Look for signs of overheating, which can indicate loose or damaged connections.

- Cleaning: Dust and debris can accumulate on connectors, which may affect performance. Using a soft brush or cloth, clean the surface of the connectors regularly.

- Check for Moisture: In environments where humidity or moisture exposure is common, ensure that connectors remain dry. Excess moisture can lead to corrosion and short-circuiting issues.

- Replacement of Damaged Connectors: If any connectors show signs of damage or wear, they should be replaced immediately to maintain the integrity of the electrical system.

Implementing these maintenance practices will not only extend the life of Pkz Connectors but also enhance the overall reliability of your electrical installations.

Case Studies: Successful Implementation of Pkz Connectors

Examining real-world applications can provide insight into the practical benefits of Pkz Connectors. Below are a few case studies that highlight their successful utilization across different sectors.

Case Study 1: Automotive Industry

In a major automotive manufacturing plant, Pkz Connectors were integrated into the assembly line robots responsible for assembling components. Given the rigorous operational environment, connectors faced challenges such as vibrations and dust contamination. By switching to Pkz Connectors, the plant reported a 50% decrease in connection failures. The connectors’ robustness against mechanical stress significantly reduced downtime and maintenance costs.

Case Study 2: Renewable Energy System

In implementing a solar energy project, engineers chose Pkz Connectors for all electrical junctions between solar panels. This decision was influenced by the connectors’ ability to resist high levels of UV radiation and moisture exposure. The solar farm saw enhanced efficiency due to minimal electrical losses and better performance during adverse environmental conditions. Subsequent data showed a significant increase in energy output, validating the initial investment in quality connectors.

Case Study 3: Smart Homes

A builder specializing in smart home technology turned to Pkz Connectors for their new development project. For communication between various smart devices—including lights, thermostats, and speakers—reliable electrical connections were paramount. The use of Pkz Connectors streamlined the installation process and ensured consistent performance across all devices. Homebuyers reported higher satisfaction rates due to the seamless integration of technology, attributable to the effective use of durable connectors.

FAQs

Q: What makes Pkz Connectors different from other connectors?

A: Pkz Connectors are designed for enhanced durability and safety, providing a reliable solution for various electrical applications with their easy installation and maintenance features. They incorporate advanced features like self-locking mechanisms and are built to minimize electrical losses.

Q: Are Pkz Connectors suitable for outdoor use?

A: Yes, Pkz Connectors are made from high-grade materials suitable for outdoor conditions, ensuring reliable performance despite environmental challenges. They are resistant to moisture, UV radiation, and other outdoor elements that can cause corrosion or deterioration.

Q: Can Pkz Connectors be used in high-voltage applications?

A: Pkz Connectors are engineered to handle a wide range of voltages, making them versatile for different applications, including high-voltage scenarios. The design ensures that they maintain integrity and provide a safe connection without risk of arcing or failure.

Q: What types of wires are compatible with Pkz Connectors?

A: Pkz Connectors are compatible with a variety of wire sizes and types. However, it is important to consult the manufacturer’s specifications to ensure that the selected connector matches the gauge and type of wire being used for optimal performance.

The Future of Pkz Connectors

As technological advancements continue to evolve, the role of Pkz Connectors in the electrical industry is set to expand. With ongoing research and development, these connectors are expected to become even more efficient, eco-friendly, and adaptable to future electrical innovations. By continuously addressing the challenges faced in electrical systems, Pkz Connectors are poised to remain a vital component in the industry for years to come.

Future iterations of Pkz Connectors may incorporate smart technology to allow for real-time monitoring of electrical connections. This capability could facilitate predictive maintenance, reducing downtime and enhancing system reliability. Additionally, advancements in materials may lead to connectors that are even more lightweight, reducing the overall weight of electrical systems without compromising strength.

As renewable energy sources continue to transform the power landscape, the need for reliable electrical connections will only grow. Pkz Connectors will likely play a key role in the development of next-generation energy systems, allowing for improved efficiency and sustainability. The adaptability of Pkz Connectors suggests that they will evolve alongside technologies such as electric vehicles, smart grids, and IoT (Internet of Things) applications.

Conclusion

Pkz Connectors represent a significant advancement in electrical connectivity solutions, offering durability, safety, and ease of use across a multitude of applications. Their design is not only versatile but also perfectly fits the modern demands of both industrial and residential installations. As the future unfolds, these connectors will continue to adapt, ensuring that electrical systems remain reliable and efficient in an ever-changing technological landscape. The ongoing commitment to innovation within this sector suggests that Pkz Connectors will be pivotal in driving progress, supporting the shift towards smarter and more sustainable electrical solutions.