Understanding Pkz Connectors in Depth

This article delves into the complexities and applications of Pkz Connectors, essential components in electronics and various technological systems. Pkz Connectors are pivotal for providing reliable electrical connections and facilitating efficient data and power transfer. Understanding their functionality and variations is crucial for industry professionals and consumers alike.

The Significance of Pkz Connectors

Pkz Connectors have emerged as critical components in modern electronics, serving to ensure reliable electrical connections across various platforms. As the demand for more efficient and high-performing electronic systems grows, the role of Pkz Connectors becomes increasingly significant. These connectors not only stabilize electrical connections but also support the robust function of interconnected systems by facilitating seamless data and power transmission. Their design and engineering are tailored to meet the evolving requirements of today's high-tech landscape, making them a pivotal element in electrical and electronic applications.

Considering these developments, manufacturers continuously enhance the capabilities of Pkz Connectors to respond to new challenges posed by advancements in technology. Additionally, as industries push the limits of speed and data capacity, the significance of efficient and reliable connectors cannot be overstated. Without such connectors, the risk of system failure and inefficiency rises, underscoring the necessity of integrating high-quality Pkz Connectors into various systems.

An Overview of Pkz Connectors

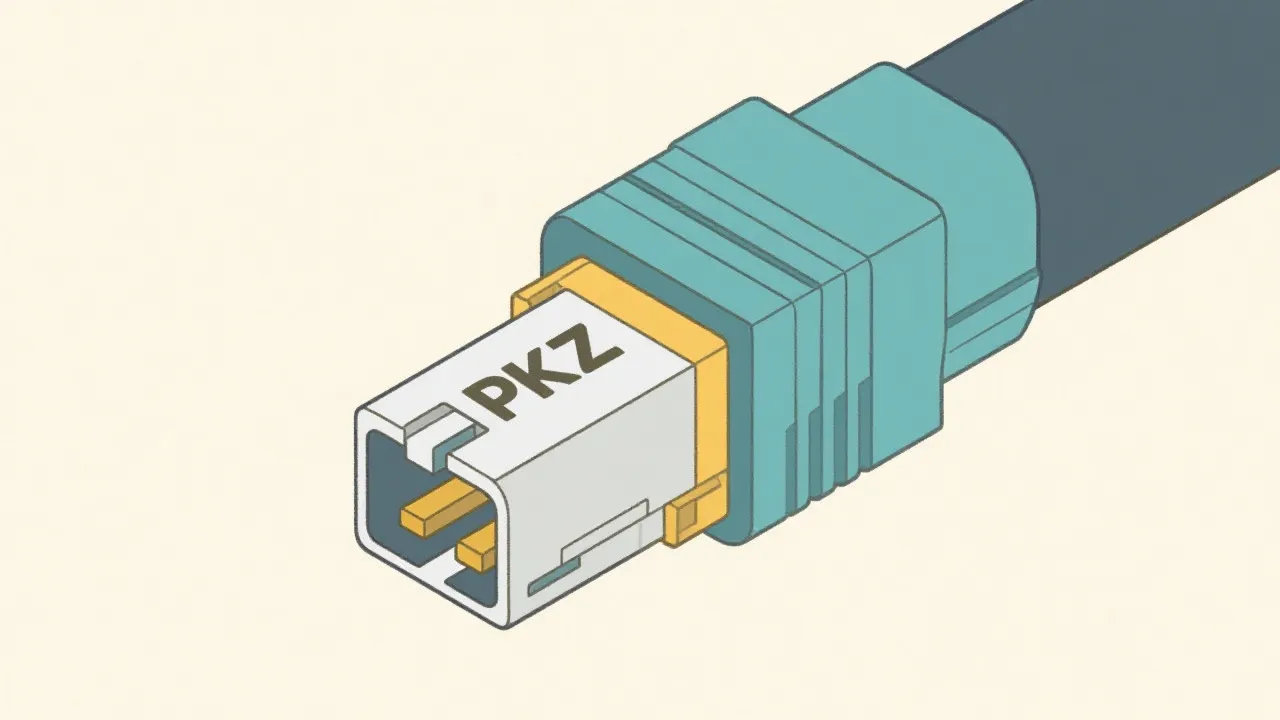

Pkz Connectors are designed to accommodate diverse applications, from industrial machinery to consumer electronics. Their construction involves materials chosen for durability and conductivity, ensuring effective performance even under rigorous conditions. This adaptability makes them ideal for use in multiple sectors, including automotive, aerospace, and telecommunication. Essentially, Pkz Connectors enable the integration of various components, fostering enhanced communication among devices.

The intricate design of Pkz Connectors often includes features that promote not just strength but also efficient electrical performance. These features can include gold plating for superior conductivity, varied pin configurations for specialized functions, and embedded locking mechanisms to prevent accidental disconnections. Each characteristic plays a critical role in ensuring that the connectors can withstand physical stresses while maintaining optimal electrical performance. Furthermore, manufacturers are increasingly deploying automated manufacturing processes that bolster precision and consistency, leading to improved reliability in connector performance.

Applications of Pkz Connectors

The versatility of Pkz Connectors is reflected in their widespread usage across various sectors. Industrial sectors rely heavily on these connectors for machinery that requires strong and stable connections. They are essential in applications requiring high durability due to environmental impacts, such as exposure to dust, moisture, and temperature fluctuations. For example, factory automation systems depend on robust connectors to maintain continuous operational productivity while minimizing downtime caused by connection failures.

In consumer electronics, Pkz Connectors are vital for devices that hinge on seamless data exchange and efficient power consumption. These connectors can be found in smartphones, laptops, and home electronics, where compact designs and high-performance characteristics are crucial. The rise of smart home devices has significantly increased the demand for reliable connectors that can facilitate constant, high-speed communication between devices, enabling them to operate efficiently as part of an integrated system.

Moreover, in the telecommunication industry, Pkz Connectors play a crucial role in maintaining the integrity of signal transmission, thereby optimizing communication networks. The deployment of fiber optics and advanced wireless communication technologies further underscores the necessity for connectors that can handle higher frequencies and data volumes without degradation. In this context, connectors must ensure minimal signal loss and maintain high fidelity in data transmission, which is essential for services like broadband internet, mobile telephony, and data centers.

Types of Pkz Connectors

Pkz Connectors are available in various forms, each crafted to fit specific needs. Understanding the different types of connectors is essential for effectively meeting application requirements. The primary types include board-to-board connectors, wire-to-board connectors, and wire-to-wire connectors. Each type boasts unique features that address distinct connectivity challenges.

For instance, board-to-board connectors are renowned for their compact design and capability to support high-density applications. These connectors allow two printed circuit boards (PCBs) to connect directly, which is integral for devices that require efficient spacing and reduced size, such as smartphones and portable electronics. Additionally, they excel in applications involving high-speed data transfer, making them indispensable in data-sensitive environments.

Wire-to-board connectors, on the other hand, are chosen for their robust connection in wiring systems. These connectors enable wires to be attached securely to a PCB, facilitating power and signal transmission while accommodating various wire gauges. Their versatility allows them to be used in numerous applications, from consumer electronics to automotive systems, where reliability and strength are paramount.

Lastly, wire-to-wire connectors are critical in creating connections between two wires without needing a circuit board. This type is important for cable networks and electrical distribution systems, providing flexibility and high-voltage capabilities. Their design allows for modular configurations and is particularly favored in automotive and aerospace applications, where space is often limited and high performance is mandatory.

Features That Distinguish Pkz Connectors

When selecting Pkz Connectors, several key features should be considered to ensure optimal performance. Understanding these features can guide engineers and designers in making the best choices for their specific applications. These include:

- Durability: Connectors must withstand environmental factors such as temperature fluctuations, humidity, and mechanical stress. This durability ensures long-term reliability in various settings, including industrial and outdoor applications.

- Conductivity: High conductivity is essential for minimizing energy loss and maintaining efficient flow in electrical systems. Connectors made from materials such as copper or those with gold plating provide excellent conductivity, which is crucial for high-performance applications that demand fast signal transmission.

- Compatibility: Connectors must be compatible with other system components to facilitate integration. Ensuring compliance with industry standards and common specifications can prevent costly rework and design modifications during production.

- Size: The connector’s size should align with the application’s spatial constraints, especially in compact systems. Miniaturization is a key trend in electronics, making the size of connectors increasingly important for modern technologies.

- Locking Mechanisms: Many Pkz Connectors feature locking mechanisms that prevent accidental disconnection which is paramount in high-vibration environments. This feature is particularly valuable in automotive and aerospace applications, wherein failure could have significant consequences.

- Ease of Assembly: Connectors designed for easy assembly can save time during installation. Features such as snap-fit designs or color-coded contacts enhance the assembly process, reducing the potential for errors.

Industry Insights

Industry experts emphasize the importance of staying current with technological advancements in connector design. As electronics evolve, so do the demands on connectors, prompting continual improvement and innovation. Pkz Connectors are at the forefront of this evolution, catering to emerging needs such as higher speed data transmission and reduction in connector size. For instance, the adoption of wireless technologies necessitates new connector designs that can support data integrity without physical connections while ensuring compatibility with existing systems.

Furthermore, as industries shift towards greener technologies, the push for eco-friendly materials and processes has also permeated the connector market. Manufacturers are increasingly exploring the use of recyclable materials and less energy-intensive production techniques, aligning their products with broader sustainability goals. This shift not only helps in compliance with environmental regulations but also appeals to a growing base of environmentally conscious consumers and businesses.

Comparison Table of Pkz Connector Types

| Type | Application | Key Features |

|---|---|---|

| Board-to-Board | High-density electronics | Compact design, high speed |

| Wire-to-Board | Integrated circuits | Strong mechanical hold, easy assembly |

| Wire-to-Wire | Cable networks | Flexibility, high voltage |

FAQs About Pkz Connectors

- What are Pkz Connectors used for? They are utilized for creating reliable electrical connections across various devices and systems, integral both in consumer gadgets and industrial systems.

- What sectors extensively use Pkz Connectors? Sectors such as automotive, aerospace, telecommunication, and consumer electronics heavily rely on these connectors, particularly in high-stakes applications where safety and performance are vital.

- How do I choose the right Pkz Connector? Consider factors such as application requirements, environmental conditions, the specific design features that the application necessitates, and adherence to industry standards.

- Are there standard specifications for Pkz Connectors? While each type may have general specifications, it is essential to adhere to industry standards applicable to particular sectors or applications for safety and compatibility.

- What innovations are occurring in the Pkz Connector industry? Innovations include advancements in materials, such as the use of lighter and more durable substances, as well as the development of smarter connectors equipped with sensors for real-time diagnostics.

- How do Pkz Connectors contribute to circuit board design? Their compact nature allows for denser layouts on PCBs, enabling more powerful and sophisticated electronic designs without increasing physical size.

Conclusion

In conclusion, Pkz Connectors are indispensable components in modern electronic systems, ensuring reliable connectivity and supporting efficient operation across a kaleidoscope of applications. Their adaptability across multiple industries underscores the importance of understanding their functionality and the impact they have on overall system performance. As technological advancements continue to shape the dynamics of electronics, Pkz Connectors will remain central to achieving high-performance, reliable systems.

With the ever-increasing need for faster data transfers, miniaturized components, and enhanced efficiencies, Pkz Connectors stand poised to adapt and thrive. As new technologies emerge, such as IoT devices and advanced automation processes, the demand for innovative connector solutions will escalate. Manufacturers will need to continue investing in research and development to create connectors that not only meet current standards but also anticipate future trends. Ultimately, the evolution of Pkz Connectors will significantly contribute to the advancement of various technologies, making them vital components in the future of electronics.

Moreover, collaboration between manufacturers, engineers, and design teams is essential to foster innovation, ensuring that Pkz Connectors evolve in line with industry needs. By waving the flag for high standards of quality and performance, those involved in the supply chain of Pkz Connectors can help shape the future of connectivity and interoperability in electronic systems. As we look ahead, the potential for Pkz Connectors to revolutionize connectivity in the digital age is vast and invigorating, insinuating new possibilities for integration and functionality in an ever-connected world.