Understanding Pkz Connectors in Depth

This article provides an in-depth look at Pkz Connectors, essential components in various industries due to their reliability and efficiency. Pkz Connectors are critical for electrical connections, ensuring secure and stable transmission of power and signals. The exploration includes their applications, benefits, and industry insights from an expert perspective, highlighting their significance in modern technology.

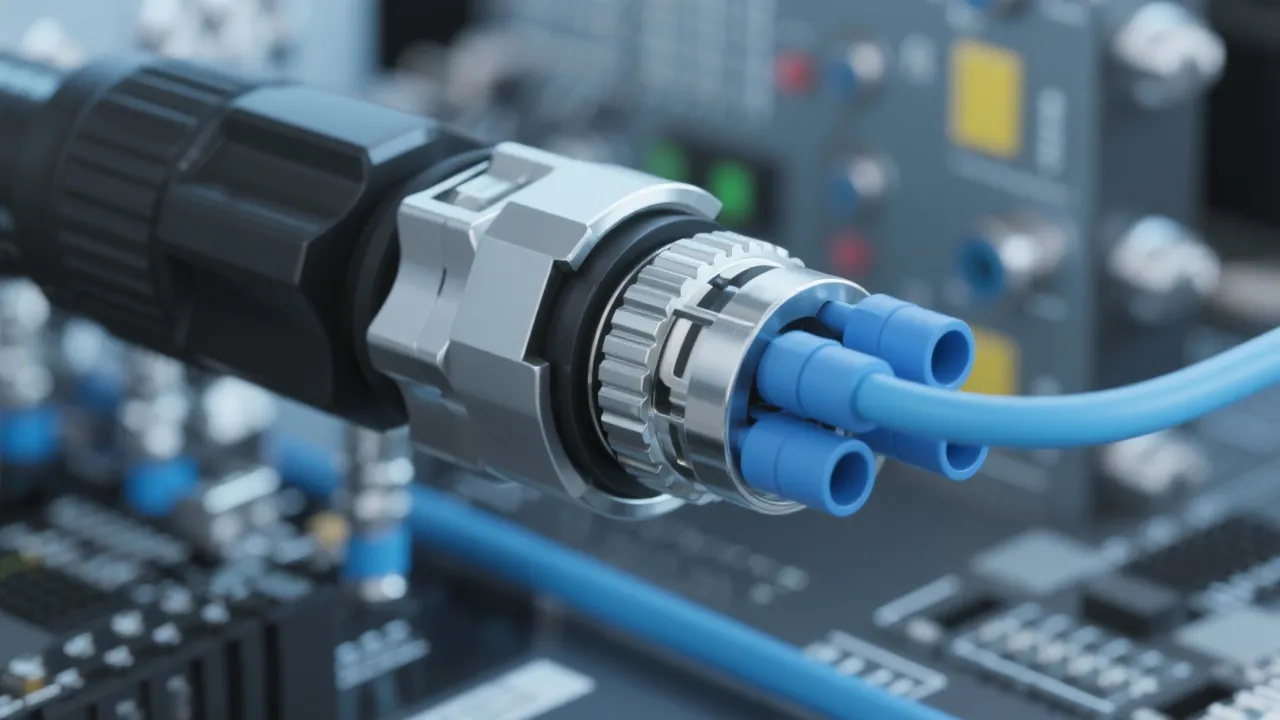

Introduction to Pkz Connectors

Pkz Connectors are at the forefront of electrical and electronic connectivity solutions. They play a vital role in ensuring that electrical systems across various industries remain functional and reliable. These connectors are specifically designed to provide stable and efficient connections while complying with stringent safety standards. Understanding the intricacies of these connectors allows professionals to select and implement the best options for their specific needs, whether in industrial, commercial, or residential settings.

Applications and Importance

Pkz Connectors are extensively used in a myriad of applications, from industrial automation systems to consumer electronics. Their design facilitates both power and data transmission in environments where reliability is paramount. One of the primary sectors benefiting from Pkz Connectors is industrial manufacturing, where machinery and equipment depend on stable connections to ensure uninterrupted operations. Additionally, they find widespread utilization in automotive applications for efficient power distribution throughout vehicles, supporting an array of electronic functions from infotainment systems to safety devices. Even in consumer electronics, such as home appliances and smart devices, the reliable performance of Pkz Connectors ensures user satisfaction and safety.

Industry reports indicate a consistent rise in their demand, particularly in sectors prioritizing automation and high-tech solutions. As smart factories emerge and demand for seamless communication between devices increases, the significance of Pkz Connectors cannot be understated. The connectors enable a level of integration that is essential for the Internet of Things (IoT), where devices communicate and collaborate, leading to improved efficiency and reduced operational costs. In this context, the dependency on robust electrical connectivity cannot be ignored, emphasizing the wide reach and criticality of Pkz Connectors across multiple sectors.

Key Benefits of Pkz Connectors

Recognized for their durability and efficiency, Pkz Connectors offer several benefits. First, they provide high resistance to environmental stresses, making them suitable for outdoor and industrial applications. The materials used in Pkz Connectors are typically sourced for their resilience against corrosion, moisture, and extreme temperatures, and thus they stand out in harsh operational environments. For example, outdoor systems that face rain, dust, or direct sunlight can rely on Pkz Connectors to maintain operational integrity.

The connectors also feature effective load handling, which supports the seamless operation of circuits. Their design is optimized to reduce power losses and heat generation, contributing to overall system efficiency. A closer look at their load handling capabilities reveals that they can accommodate both steady-state currents and transient loads without performance degradation. Moreover, users value Pkz Connectors for their ease of installation, reducing time and labor costs associated with complex wiring needs. Innovations in connector technology have led to plug-and-play designs that minimize installation time while maximizing reliability. For instance, pre-terminated cables with Pkz Connectors allow for quicker setup and reduced human error during installation.

Expert Insights on Connector Technology

From an expert's perspective, the significance of connectors like the Pkz multi-dimensional in modern industries cannot be ignored. As technology advances, the demand for connectors that can handle higher data rates and power levels has escalated. Pkz Connectors address these needs efficiently, standing out due to their advanced design and robust materials. Industry experts emphasize the importance of compatibility with evolving technologies, and Pkz Connectors have evolved alongside these technological advancements, ensuring they meet current and future requirements.

Furthermore, experts underline the role of connectors in system scalability. As more devices are integrated into existing systems, the need for connectors that can support increased loads and facilitate new functionality becomes paramount. In industries such as telecommunications, where network capacity continuously needs expansion, Pkz Connectors provide the flexibility required for efficient upgrades. Their modular design allows for the scalability of connectivity solutions which in turn supports future upgrades without the need for significant rewiring or redesign.

Technical Specifications and Customization Options

Pkz Connectors offer various specifications to cater to different industrial requirements. These include current ratings, voltage capabilities, and operating temperature ranges. The adaptability of these connectors allows for customization, making them suitable for specific needs without compromising on performance. For example, in applications that face extreme temperatures, connectors can be customized to withstand specific thermal conditions, ensuring system reliability over prolonged periods.

| Specification | Details |

|---|---|

| Current Rating | Ranges from 5A to 50A, depending on application needs. |

| Voltage Range | Operates efficiently between 12V and 1000V. |

| Environmental Resistance | Handles temperatures between -40°C to 85°C, making them ideal for varying climates. |

| Customization | Available in different sizes and configurations for tailored solutions. |

Moreover, specific connectors can be tailored to integrate seamlessly within a broader system, be it a factory automation setup or an automotive electrical architecture. The ability to bring together multiple connection types, such as power and data in a single connector, simplifies wiring and enhances the overall functionality of devices. Engineers appreciate having the option to select connectors that can also facilitate EMI shielding, ensuring that electronic devices operate without interference from electromagnetic signals. This level of customization is crucial, especially in sensitive applications requiring strict adherence to safety and communication protocols.

Commonly Used Materials in Pkz Connectors

The performance and durability of Pkz Connectors heavily depend on the materials used in their construction. High-quality metals such as copper and tin-plated brass are often used for contacts to ensure excellent conductivity and reduce the likelihood of oxidation. For insulators, materials such as nylon and thermoplastic elastomers (TPE) are commonly utilized due to their strong dielectric properties and durability under mechanical stress.

In addition to base materials, many Pkz Connectors are manufactured with specific coatings or treatments to enhance their resistance to environmental factors. For instance, connectors utilized in marine applications may undergo processes such as anodizing or applying a special anti-corrosive layer, thus ensuring longevity in salty water environments. This attention to materials encapsulates the ethos of producing connectors that are not only effective but resilient across a range of scenarios.

Maintenance and Longevity of Pkz Connectors

Ensuring the longevity and reliability of Pkz Connectors requires appropriate maintenance practices. Though designed for durability, connectors can still experience wear from environmental factors or mechanical movements. Regular inspections and maintenance checks are vital for identifying potential issues early on. This includes monitoring connections for signs of wear, corrosion, or thermal degradation.

For outdoor applications, protective measures are essential. Implementing enclosures or coverings for exposed connectors can significantly increase their lifespan. Regular cleaning to remove dirt and grime can also enhance connectivity and prevent interference. In industrial settings, where dust and harsh chemicals may be prevalent, the use of protective coatings or seals can further prolong connector life and performance.

Best Practices in Connector Selection

Choosing the right Pkz Connector involves several key considerations, ensuring safety and performance are kept at the forefront. Firstly, understanding the electrical specifications such as current, voltage, and environmental conditions is crucial. Additionally, assessing the application environment—whether it is indoors, outdoors, or subject to extreme temperatures—plays a significant role in selection.

Another factor to consider is the connector type. Pkz Connectors come in various forms including circular, rectangular, and modular options, each designed for specific applications. Understanding the compatibility of these types with your devices and systems is essential to avoid connectivity issues. Furthermore, engaging with trusted suppliers who can provide insights and recommendation based on real-world applications may enhance the decision-making process. They often have knowledge of the latest advancements in connector technology, offering guidance that aligns with industry standards and practices.

FAQs

What industries very commonly use Pkz Connectors?

Pkz Connectors are widely used across electronics, automotive, industrial manufacturing, and telecommunications sectors. Their versatility and reliability make them a preferred choice in environments ranging from high-tech laboratories to rugged industrial plants.

Can Pkz Connectors withstand harsh environmental conditions?

Yes, they are specifically designed to operate effectively under various environmental stresses, including moisture and high temperatures. This makes them ideal for both outdoor and industrial applications where reliable connections are vital.

Are there specific standards for Pkz Connectors?

These connectors comply with international safety and quality standards, ensuring reliable performance in critical applications. Certifications such as UL, CE, and RoHS compliance are common, adding value to the reliability and safety of the connectors.

How do I choose the right Pkz Connector for my needs?

Consider the electrical requirements and environmental conditions of your application. Consulting with a supplier or industry expert can also provide tailored advice. Furthermore, analyzing past applications and performance reports can give vital insights into what types of connectors have met requirements successfully.

Future of Pkz Connectors and Connectivity Solutions

As technology continues to evolve, so too does the demand for innovative connectivity solutions. The future landscape for Pkz Connectors is promising, with ongoing developments to meet the needs of advanced technologies such as renewable energy systems, automation in manufacturing, and increased use of smart technologies in residential applications. The integration of artificial intelligence (AI) into industrial settings is set to change how connectivity solutions are designed, and Pkz Connectors are likely to evolve to maintain their relevance in these sectors.

Trends indicate a growing emphasis on miniaturization, as devices become smaller and more integrated. Pkz Connectors will need to adapt by offering compact designs that do not compromise on functionality or safety. Furthermore, as the focus on sustainability grows, there will be increased scrutiny on the materials used in connector production. Manufacturers will likely strive to develop eco-friendly alternatives, ensuring that electrical connectors are not only efficient but also environmentally responsible.

Understanding these trends and preparing for changes in connector technology will allow businesses to remain competitive and maintain operational efficiency. Incorporating Pkz Connectors into future projects will require staying abreast of advancements in connector design and performance characteristics. Companies that prioritize innovation in their connectivity solutions will be better positioned to capitalize on emerging market opportunities.

Conclusion

Understanding the importance and functionality of Pkz Connectors is crucial for anyone involved in industries reliant on electrical connections. Their distinct benefits make them indispensable in ensuring high performance and safety. Moreover, as industries expand and technology evolves, the role of Pkz Connectors will only grow in significance. Continued advancements in connector technology suggest that Pkz Connectors will remain an integral part of various systems. Remaining informed about their capabilities and proper applications allows businesses to maximize efficiency and minimize downtime. By embracing innovation and preparing for the future of connectivity, industries can ensure they harness the full potential of these essential components.