Understanding Modern Pkz Connectors

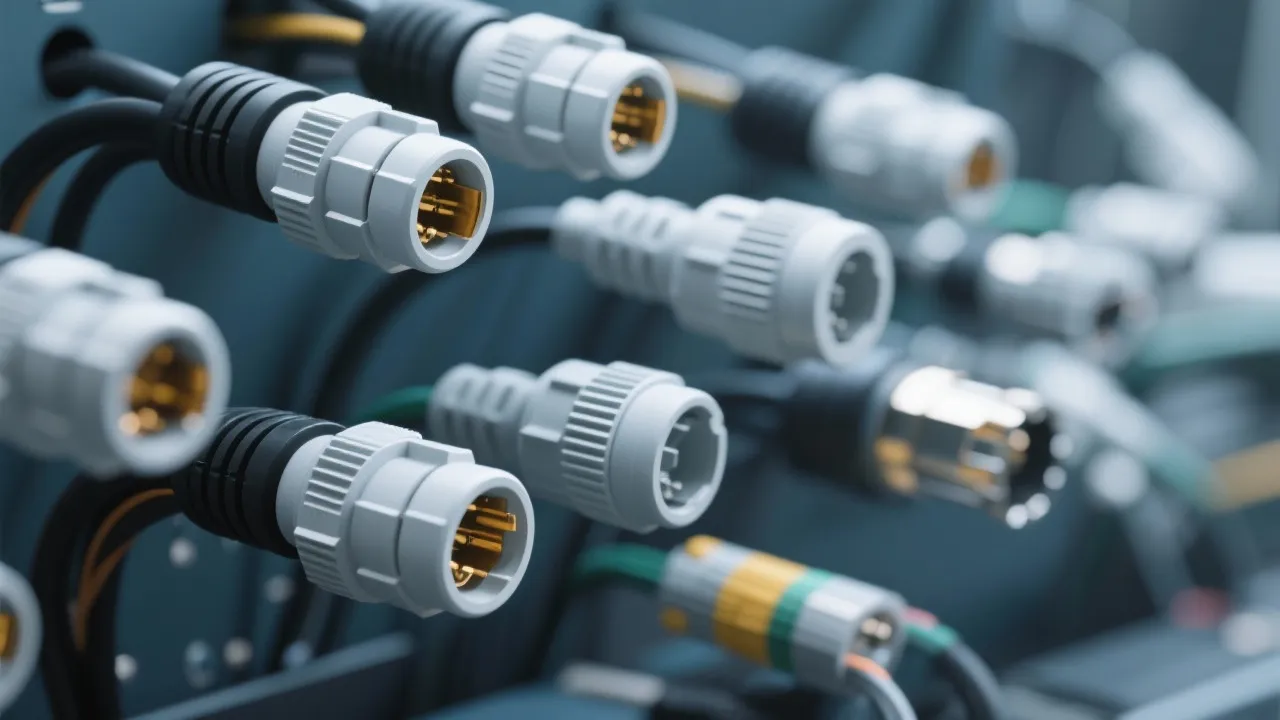

This in-depth guide explores the significance of Pkz Connectors in modern electrical and electronic applications. As vital components in creating secure and efficient electrical connections, Pkz Connectors revolutionize how industries leverage interconnectivity for various applications. Their reliable and versatile nature makes them indispensable in advanced electronic circuitry and systems.

Introduction to Pkz Connectors

Pkz Connectors have established themselves as indispensable components in contemporary electrical and electronic applications. Known for their robust performance and reliability, these connectors are integral to creating secure and efficient electrical connections. As technology continues to evolve, the demand for more efficient and reliable connectivity solutions is at an all-time high. Pkz Connectors stand out in this landscape due to their innovative design and tailored applications, addressing the needs of various industries.

Importance of Pkz Connectors

One of the very critical aspects of Pkz Connectors is their ability to ensure secure electrical connections in challenging environments. Their design typically emphasizes high durability, resistance to environmental stressors, and a reliable connection mechanism, making them suitable for industrial, automotive, and consumer electronics applications. In a world where electronic devices are constantly being pushed to their limits, the importance of reliable connectors cannot be overstated. Whether it's the vibration inside a moving vehicle or the moisture present in an industrial setting, Pkz Connectors maintain their integrity, which is vital for the seamless operation of devices.

Technical Overview of Pkz Connectors

Pkz Connectors are characterized by their modular design, which allows easy assembly and maintenance. They are typically composed of high-quality materials such as polyamide for insulation and brass or copper for conductive elements, ensuring longevity and efficient conductivity. Their various configurations cater to different needs, from simple wire-to-wire connections to complex board-to-board assemblies. This versatility plays a crucial role in the design of electronic systems, allowing for easy upgrades and modifications as technology advances or as user requirements change. The innovative engineering behind Pkz Connectors reflects a deep understanding of electrical needs, leading to the development of connectors that not only perform well but also adapt to different environments over time.

Applications of Pkz Connectors

The versatility of Pkz Connectors makes them suitable for various applications, demonstrating their critical role in various industries:

- Consumer Electronics: Pkz Connectors are often used in mobile phones, laptops, and other personal devices, where compact size and reliable connectivity are paramount. In the fast-paced consumer electronics market, where design aesthetics and functionality must coexist, these connectors offer the necessary balance, allowing manufacturers to create thinner and lighter devices without compromising on performance.

- Automotive Industry: In vehicles, these connectors ensure reliable connections for control units and sensors, where durability and resistance to vibration are critical. Automotive applications often face unique challenges, such as extreme temperatures, exposure to dirt, and vibrations, which Pkz Connectors are engineered to withstand, thus enhancing the safety and efficiency of modern vehicles.

- Industrial Automation: They serve as crucial components in control cabinets and systems requiring high reliability and precision, especially in harsh manufacturing environments. As industries turn towards automation and smart technologies, the need for reliable interconnect solutions becomes ever more pronounced, and Pkz Connectors play an essential role in facilitating this evolution.

- Telecommunication Systems: In telecommunications, Pkz Connectors are vital for maintaining signal integrity between devices and over long distances. The increasing demands for higher bandwidth and lower latency in communication systems make these connectors essential to ensuring that signals remain clear and robust.

- Aerospace and Defense: Within these sectors, Pkz Connectors are preferred for their performance in extreme conditions, including high altitudes and varying atmospheric pressures. The rigorous standards required in aerospace applications necessitate products that are thoroughly tested and proven to perform reliably under pressure, literally and figuratively.

Reasons to Choose Pkz Connectors

Pkz Connectors offer numerous advantages over traditional connectors, making them a preferred choice among engineers and designers alike. Their benefits can be dissected as follows:

| Feature | Benefit |

|---|---|

| Modularity | Facilitates varied configuration setups and easy system upgrades, significantly reducing downtime during maintenance. This aspect encourages higher design flexibility in projects that require rapid changes or enhancements. |

| Durability | Ensures reliable performance under extreme conditions, reducing replacement needs. High-quality materials and a robust design philosophy guarantee that these connectors perform well over extended periods, even in demanding settings. |

| High Conductivity | Minimizes energy losses and enhances overall system efficiency, leading to lower operating costs for electronic devices. As technology pushes for greener and more efficient solutions, using connectors that support these goals is essential. |

| Temperature Resistance | Withstand a wide temperature range which is crucial for applications in both warm and cold environments. This quality makes them suitable for both external and internal electronic devices without risk of failure. |

| Easy Installation | Designed for simple plug-and-play operations, minimizing manual labor and reducing installation time and costs significantly. This aspect is particularly beneficial for manufacturers looking to keep production moving swiftly. |

FAQs

What are the main types of Pkz Connectors?

Pkz Connectors come in multiple types, including wire-to-wire, wire-to-board, and board-to-board connectors. Each type is designed to meet specific application needs. For instance, wire-to-wire connectors are ideal for connecting individual wires together, wire-to-board connectors are used to connect wires directly to a printed circuit board (PCB), and board-to-board connectors allow for the interconnection of two PCBs.

How do Pkz Connectors withstand harsh environments?

Pkz Connectors are constructed from durable materials and designed to resist temperature fluctuations, vibrations, and moisture, making them ideal for various challenging environments. These characteristics are vital for industries that encounter extreme conditions, such as locations that reach high humidity levels, outdoor settings with wide temperature variations, or manufacturing floors with high vibration machinery.

Where can I purchase Pkz Connectors?

Pkz Connectors can be sourced from reputable electrical manufacturers and distributors specializing in electronic components. Ensure that they meet your specific technical requirements for optimal performance. Reputable suppliers often provide detailed specifications and certifications, affording engineers confidence in their compatibility and reliability.

Are Pkz Connectors customizable?

Yes, many suppliers offer customizable options for Pkz Connectors to suit specific application needs, such as different connector sizes, materials, and configurations. Customization capabilities can address unique design requirements that standard connectors may not fulfill, enabling engineers to achieve specific project objectives.

What quality standards do Pkz Connectors adhere to?

Pkz Connectors commonly meet established industry standards such as UL, IEC, and RoHS, which ensure compliance with safety, quality, and environmental regulations. Adhering to these standards is critical for manufacturing processes and offers assurance in terms of product quality and performance.

How do I determine the right Pkz Connector for my project?

Selecting the appropriate Pkz Connector involves understanding the specific requirements of your application, including environmental factors, electrical specifications, and space constraints. Conducting a thorough analysis of these parameters and consulting with connector specialists can guide you to make informed choices.

Conclusion

Pkz Connectors are a testament to modern advancements in connectivity solutions, offering reliability, adaptability, and efficiency across various industries. Understanding their applications and benefits can significantly enhance the design and performance of electronic systems. The evolution of these connectors not only reflects technological advancement but also emphasizes the importance of thoughtful engineering solutions in an increasingly connected world. For more information on Pkz Connectors, consulting with industry experts or connecting with recognized manufacturers may provide additional insights tailored to specific needs.

Future Developments in Pkz Connectors

As technology continues to evolve rapidly, Pkz Connectors are poised to adapt to the emerging trends within the industry. Innovations in material science and engineering techniques are on the horizon, which may lead to the creation of even more robust and efficient connector solutions. Emerging applications, such as electric vehicles and smart cities, demand connectors that not only meet current challenges but also anticipate future connectivity requirements.

In the coming years, we may see developments aimed at enhancing the electrical performance of Pkz Connectors, possibly introducing features such as self-locking mechanisms that simplify user installation or connectors that offer greater data transmission capabilities without interference. Such innovations would further cement Pkz Connectors' position as a staple in modern electronics.

Sustainability and Environmental Considerations

With today's emphasis on sustainability and environmental responsibility, many manufacturers are beginning to prioritize eco-friendly materials and practices in their production processes. Pkz Connectors are likely to follow suit, with a growing focus on using recyclable materials and reducing waste during production. This aligns with global efforts to combat climate change and promote sustainability within the electronics sector, ensuring that products not only meet performance metrics but also environmental standards.

Furthermore, the implementation of circular economy principles in connector design can lead to longer product life cycles and improved end-of-life handling options. This could take form through the design of connectors that are easier to dismantle and recycle, promoting a more environmentally friendly approach within an industry characterized by rapid technological obsolescence and high turnover rates.

Real-World Case Studies

To better understand the practical applications of Pkz Connectors, examining real-world case studies can be illuminating. For instance, a leading automobile manufacturer recently integrated Pkz Connectors into their electric vehicles. By selecting connectors designed for high voltage and durability, they significantly improved the reliability of their battery management systems. This case illustrates how the right connector choice can lead to enhanced safety and performance in critical automotive applications.

In the consumer electronics sector, a smartphone manufacturer opted for Pkz Connectors to streamline their assembly process, reducing the overall production time by 20%. The modular design allowed for quick adjustments on the assembly line, accommodating changes in device design while maintaining high performance. Such cases reflect how choosing the right connectors can have a tangible impact on operational efficiency and product quality.

Advancements in Testing and Quality Assurance

To meet the rigorous demands of today's applications, ongoing advancements in testing methods and quality assurance processes are becoming more prominent. Manufacturers of Pkz Connectors are increasingly implementing sophisticated testing procedures to ensure product reliability and safety. This includes environmental testing simulating extreme conditions, electrical testing to verify conductivity, and mechanical testing to assess durability under stress.

These enhanced quality control measures not only help in identifying potential failures before products reach the market but also contribute to the long-term satisfaction of end-users. The continued emphasis on rigorous testing standards affirms a commitment to quality and reinforces Pkz Connectors’ role in ensuring seamless connectivity in critical applications.

Conclusion and Call to Action

In summary, Pkz Connectors exemplify the integration of technological advancement with practical application in the world of electronics. Their diverse applications, coupled with advancements in technology and manufacturing practices, signify their importance as foundational elements in modern electronic devices. As the industry continues to shift towards higher performance and sustainability, Pkz Connectors are expected to evolve alongside these trends, setting the stage for future innovations in connectivity solutions.

Understanding the breadth of applications and the advantages these connectors provide is crucial for engineers and designers making informed decisions regarding their projects. For anyone looking to enhance their electronic designs with reliable and efficient connectors, exploring Pkz Connectors will undoubtedly be worthwhile. Engaging with manufacturers and industry experts not only aids in sourcing the appropriate connectors but also enables collaboration on future developments that fulfill evolving technological needs.