Understanding Pkz Connectors in Depth

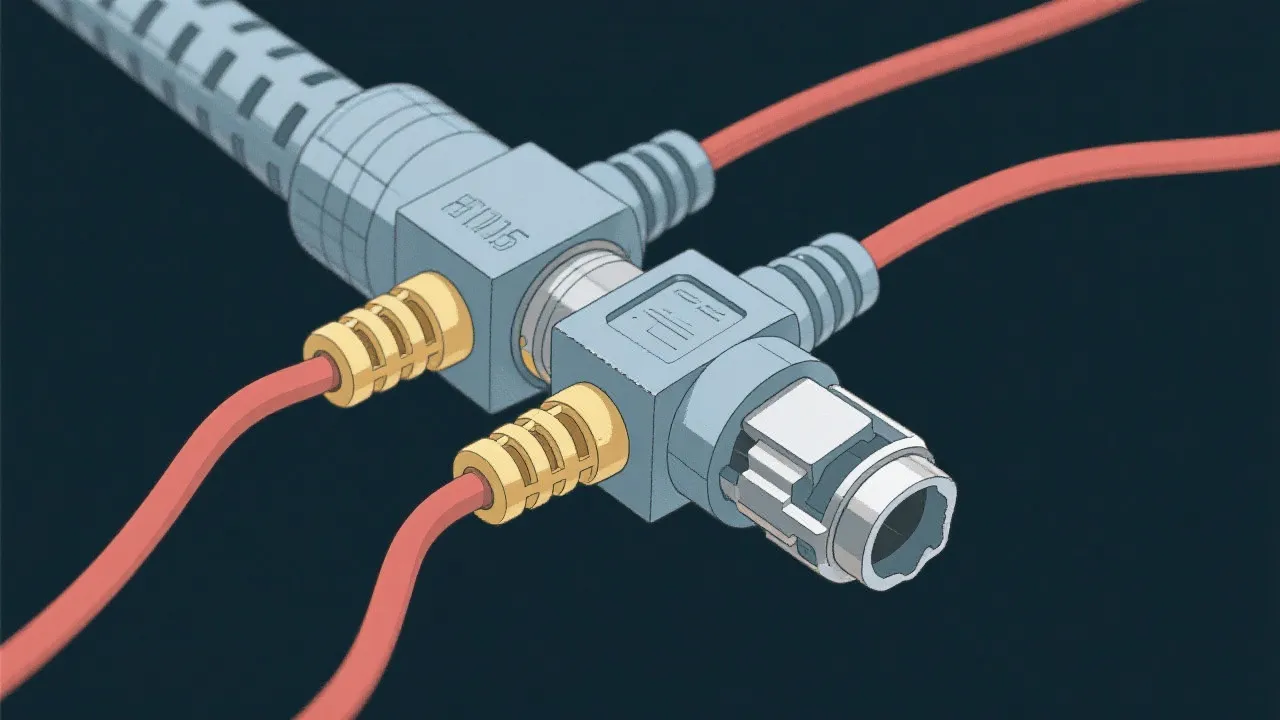

This article provides an insightful look into Pkz Connectors, examining their role in electrical systems. Primarily used for connecting electrical circuits and devices safely and reliably, Pkz Connectors are vital components across various industries. Their importance has grown alongside advances in technology, where precise and durable connections are increasingly necessary.

The Role of Pkz Connectors in Modern Technology

In the fast-evolving landscape of modern technology, Pkz Connectors play a crucial role in ensuring robust and versatile connections across a plethora of electrical applications. Their unique design is optimized to carry electrical currents effectively between diverse devices, solidifying their place in numerous sectors, from automotive to telecommunications. The attributes such as durability, flexibility, and superior connectivity make Pkz Connectors indispensable not only in domestic settings but also in various industrial contexts where reliability is paramount.

How Pkz Connectors Are Revolutionizing Connectivity

At the heart of their functionality, Pkz Connectors deliver a stable platform for current transmission, which is critical in maintaining system integrity and optimal performance. Unlike some traditional connectors that might falter under pressure, Pkz Connectors stand out by combining cutting-edge engineering with unparalleled reliability. These connectors effectively overcome challenges typical of complex electrical environments, such as overheating, corrosion, and mechanical stress, elevating standards for electrical connections worldwide.

Key Features of Pkz Connectors

- Durable Contacts: The contacts within Pkz Connectors are designed to ensure a stable and long-lasting electrical connection. Materials used in the construction of these contacts are resistant to wear and tear, a feature that significantly reduces the frequency of replacements over time.

- Flexibility: Pkz Connectors can adapt to various configurations and shapes, making them suitable for an array of industrial purposes, including tight spaces where traditional connectors may not fit. This adaptability extends their usability across many applications, enhancing their desirability in the market.

- High Conductivity: These connectors minimize electric resistance, which supports better electrical flow. The use of advanced conductive materials ensures that energy loss due to resistance is significantly reduced, leading to more efficient system operations.

- Environmental Resistance: Pkz Connectors are engineered to withstand harsh operating conditions. They resist temperature fluctuations, moisture, and corrosive elements, making them particularly well-suited for outdoor applications or in industries such as marine and agriculture.

The Science Behind Pkz Connectors

Diving deeper into the technology and design behind Pkz Connectors can greatly enhance appreciation for their exceptional efficiency. These connectors are engineered for precision and performance, employing advanced materials and innovative designs aimed at minimizing electricity loss and preventing overheating during use. The choice of materials is paramount; for instance, advanced alloys that combine conductivity with strength are often utilized, alongside high-quality insulating compounds that protect against electrical arcing and short circuits.

Furthermore, the manufacturing processes of Pkz Connectors involve rigorous quality control to ensure each connector meets strict performance standards. Techniques like precision stamping, molding, and surface treatment are employed to enhance durability and performance. This meticulous approach not only maximizes the connectors’ lifespan but also ensures that they continue to perform under demanding conditions without degradation.

Applications and Advantages of Pkz Connectors

In various industries, Pkz Connectors serve pivotal roles. Their applications range widely, adapting to the unique requirements of different sectors. Whether in automotive manufacturing, telecommunications, electronics, or heavy machinery, these connectors facilitate efficient electrical connections that can endure the rigors of daily operation. Their main advantages include the ability to maintain a reliable and consistent electrical connection, which is vital for reducing downtime caused by faulty connectivity. This reliability plays an essential role in increasing productivity and minimizing overall maintenance costs.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Connecting electrical systems within vehicles. | Improved safety and reduced risk of electrical failures, contributing to higher quality control in production. |

| Telecommunications | Linking communication devices and infrastructures. | Enhanced signal clarity and reduced interference, which is crucial for maintaining seamless communication services. |

| Electronics | Used in consumer electronics for reliable connectivity. | Enhances product longevity and performance, contributing positively to customer satisfaction and reducing return rates. |

| Heavy Machinery | Integrating electrical systems in equipment across construction and manufacturing. | Ensures reliability of operation, thereby enhancing safety and productivity on-site. |

| Medical Devices | Connecting components within diagnostic and imaging equipment. | Ensures the accuracy and reliability of medical tests and diagnostics, ultimately impacting patient care. |

Ensuring Quality: Choosing the Right Supplier

When sourcing Pkz Connectors, selecting a reputable supplier is of utmost importance. Manufacturers should seek suppliers that offer certified products backed by industry-approved standards. Certifications ensure that the connectors can withstand the specific demands of their intended applications. It is equally important to consider warranties, as these provide peace of mind regarding the product's reliability throughout its service life.

Positive supplier reviews from other manufacturers can act as an invaluable resource for making an informed decision. A supplier with a solid track record is likely to offer products that meet strict quality standards and provide excellent customer service. Additionally, ensure that suppliers adhere to compliance guidelines set forth by regulatory bodies, as this compliance is critical in avoiding future connectivity issues that may arise due to subpar products.

FAQs

- What are Pkz Connectors used for?

Pkz Connectors are primarily used for establishing electrical connections in various devices and systems across multiple industries. Their versatility makes them suitable in applications ranging from automotive electrical systems to telecommunications and consumer electronics. - What makes Pkz Connectors different from other connectors?

The durability, adaptability, high conductivity, and resistance to environmental stressors set Pkz Connectors apart. These features ensure that they maintain connectivity integrity even in challenging operating conditions, which is not always the case with other standard connectors. - Can Pkz Connectors be used in extreme environments?

Yes, Pkz Connectors are specifically designed to withstand harsh conditions. They are often treated with special coatings and made from high-quality materials that resist moisture, temperature extremes, and corrosive elements, making them suitable for demanding applications. - Are Pkz Connectors compliant with industry standards?

Most reputable manufacturers ensure their Pkz Connectors meet essential industry standards. It’s crucial to verify certifications from suppliers to ensure they align with relevant regulations in your industry. - How do I ensure I am purchasing high-quality Pkz Connectors?

Look for trusted suppliers who provide detailed product specifications, certifications, and warranties. Researching supplier reviews and seeking products that meet stringent industry standards will help ensure quality.

In conclusion, understanding the utility and benefits of Pkz Connectors can significantly enhance the efficiency and reliability of modern electrical systems. By facilitating robust connections, these connectors contribute to the seamless operation of devices and systems across various industries. As technology continues to advance, the role of Pkz Connectors becomes ever more essential, underpinning the interconnectedness of today’s digitally-driven world. Their evolution reflects the increasing demands of modern applications, where the highest standards of performance, safety, and reliability are non-negotiable. The future of Pkz Connectors looks promising, driven by ongoing innovations and the need for cutting-edge solutions in an increasingly electrified global landscape.

Looking Ahead: The Future of Pkz Connectors

As we move further into the age of technology, the demand for reliable and efficient electrical connections will only grow. Pkz Connectors are positioned to meet this demand, with advancements in materials science and engineering driving the production of even more efficient models. Innovations may include the integration of intelligent connectors with built-in diagnostics that can provide real-time information on the status of electrical connections, enhancing maintenance procedures.

Moreover, as industries push toward greener solutions, Pkz Connectors will need to evolve to meet the growing emphasis on sustainability. This could involve the adoption of eco-friendly materials that maintain performance while reducing environmental impact. Such changes represent a significant opportunity for manufacturers to lead in sustainability while catering to the next generation of electrical applications.

Real-World Examples of Pkz Connectors in Action

To illustrate the impact of Pkz Connectors in real-world applications, consider a high-end electric vehicle that incorporates Pkz Connectors throughout its electrical systems. These connectors facilitate communication between the battery management system, electric motors, and on-board electronics, ensuring seamless operation while enhancing safety standards. Their reliable performance is vital to providing drivers with efficient and safe vehicles that meet rigorous performance standards.

In telecommunications, Pkz Connectors help sustain the backbone of our communication networks. For instance, they might connect various network devices such as routers and switches in a data center environment. The ability for these connectors to minimize signal loss directly contributes to maintaining high-speed internet services, supporting business operations and customer satisfaction alike.

Additionally, in medical devices, Pkz Connectors have been crucial. In imaging systems such as MRI and CT scans, where electrical connectivity is paramount for accurate diagnostics, these connectors provide the reliability needed to deliver precise healthcare solutions. Their role in ensuring that equipment functions without disruption reflects the importance of quality connectors professionally produced for critical applications.

Conclusion

As we reflect on the importance of Pkz Connectors, it becomes clear that they are not just components but foundational elements of modern technology. Their design and engineering have set new standards for reliability, adaptability, and performance across various sectors. Understanding their functionality and application opens avenues for innovation, enhancing both existing technologies and paving the way for future advancements. As industries evolve to meet new challenges, the continued development and enhancement of Pkz Connectors will remain essential to bridging electrical connections that power our world.