Understanding PKZ Connectors

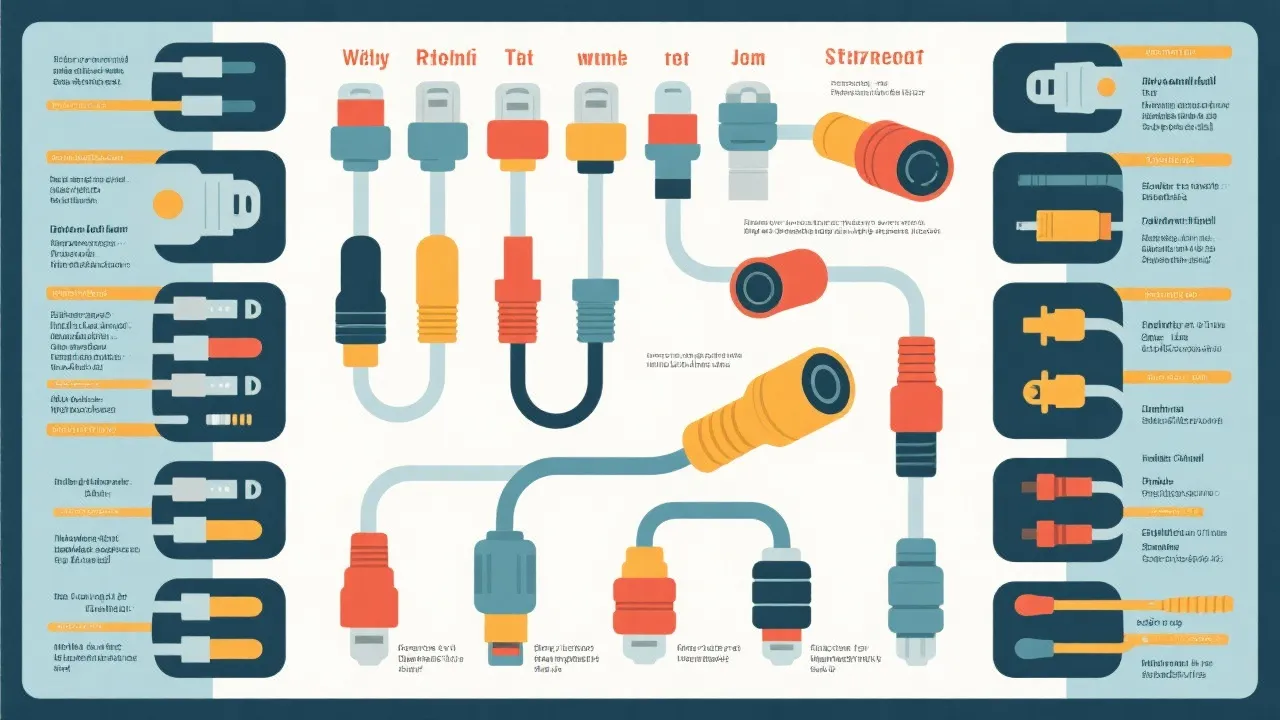

In this guide, we explore the role of PKZ Connectors in modern electrical systems, highlighting their importance for secure and reliable connections across various applications. PKZ Connectors are designed to provide optimal functionality in industrial and commercial settings, ensuring safety and efficiency in power distribution, as well as in complex electronic and data communication systems.

Introduction to PKZ Connectors

PKZ Connectors play an essential role in the electrical and data communication industry. They are fundamental components that ensure secure and efficient connections in various applications, from industrial power systems to intricate electronic networks. Understanding PKZ Connectors' design, capabilities, and applications is crucial for professionals seeking to enhance system reliability and performance.

The importance of connectors like PKZ cannot be overstated in today's fast-paced technological landscape. These components are not just passive interconnections; they are dynamic elements that help facilitate data transfer, signal integrity, and overall system efficiency. In a world increasingly driven by automation, connectivity, and data exchange, the demand for reliable connectors continues to grow, making an understanding of products like PKZ essential for engineers, technicians, and project managers.

Key Features and Benefits

PKZ Connectors are known for their robustness and reliability, which makes them suitable for demanding environments. These connectors provide a stable and durable interface between different system components, reducing the risk of connection failures. Some of their prominent features include:

- High-Durability: Built with high-quality materials to withstand harsh conditions and continuous use. PKZ Connectors often incorporate advanced materials that are resistant to abrasion, temperature fluctuations, and corrosive environments.

- Efficient Signal Transmission: Designed to minimize electrical resistance and interference, enhancing signal integrity. This ensures that data transmission remains fast and error-free across long distances and diverse environmental conditions.

- Simplified Installation: User-friendly designs that simplify the installation and maintenance process, from color-coded coding systems for easier wiring to intuitive locking mechanisms that make connecting and disconnecting a hassle-free experience.

- Versatility: Suitable for a broad range of applications in various industries, including manufacturing, automotive, telecommunications, medical technologies, and renewable energy sectors. This adaptability is bolstered by extensive customization options that allow the connectors to meet the specific requirements of each application.

Applications of PKZ Connectors

PKZ Connectors are employed across diverse sectors due to their adaptability and reliability. Some common applications include:

- Industrial Automation: Used in controlling machinery and facilitating communication between various control systems. Here, they serve as critical junctions that handle power distribution and signal communication in everything from assembly lines to robotics.

- Data Communication Networks: Ensure reliable data transmission in both wired and wireless communication setups. In data centers, for instance, these connectors are vital for linking servers to networking equipment, optimizing throughput and minimizing latency.

- Automotive Industry: Integral in automotive electrical systems, assisting in the management of power and signal distribution. As vehicles become increasingly electrified and software-driven, the demand for high-performance connectors that can deliver both power and data is growing, making PKZ Connectors an ideal choice.

- Aerospace and Defense: Essential for complex systems that require high precision and reliability. In these applications, PKZ Connectors are frequently utilized in communication systems, navigation equipment, and various onboard electronics to ensure that connections remain intact even in extreme conditions.

- Medical Equipment: In the healthcare sector, PKZ Connectors support the reliable operation of diagnostic machines, patient monitoring systems, and surgical tools, where consistent performance can directly impact patient safety and care.

- Renewable Energy: With the growing emphasis on sustainable energy solutions, PKZ Connectors are increasingly found in solar power systems, wind turbines, and electrical battery storage systems, helping ensure efficient and durable connections in environments that may be exposed to extreme weather conditions.

Considerations for Selection

When selecting PKZ Connectors, professionals should consider several technical specifications and environmental factors to ensure optimal performance:

- Current and Voltage Ratings: Choose connectors that can handle the system's electrical load without overheating. It's imperative to analyze the electrical specifications of the entire system to ensure the correct match.

- Environmental Resistance: Considerations such as temperature, humidity, and exposure to chemicals need to be accounted for. Connectors may be rated for specific IP (Ingress Protection) levels that define their resistance to dust and moisture, which should be matched to the operating environment.

- Compliance with Standards: Ensure the connectors meet industry-specific standards and certifications. Compliance with international and local electrical standards, such as IEC, UL, and RoHS directives, is critical in ensuring safety and reliability.

- Compatibility: Ensure the chosen connectors are compatible with existing system components, in terms of both mechanical fit and electrical characteristics, to avoid introducing additional points of failure.

- Cost and Availability: Finally, evaluate not just the initial cost but also the long-term durability and performance over time, including availability. This is particularly critical in industries that rely on just-in-time production processes.

Installation and Maintenance Tips

Proper installation and maintenance of PKZ Connectors are vital for their longevity and performance. Here are some expert tips:

- Ensure all contacts are clean and free from corrosion before installation. Use appropriate cleaning agents compatible with connector materials to avoid damaging them.

- Follow manufacturer guidelines for torque and alignment during installation, as improper torque can lead to mechanical failure over time.

- Perform regular inspections to check for signs of wear and tear. Look for discoloration, bent pins, and other irregularities that may indicate a potential failure.

- Use appropriate tools and techniques for connector disassembly and reassembly to avoid damage. Employing specialized tooling can ensure consistent torque application and prevent damage to connectors.

- Document installation procedures and conduct periodic testing to ensure that the connections remain secure and effective over time, especially in high-stakes environments such as healthcare and aviation.

Industry Trends and Innovations

The connector industry is evolving with advancements in technology and increased demand for high-performing and compact solutions. Some current trends include:

- Miniaturization: Development of smaller connectors that save space without compromising performance. This trend is particularly evident in the automotive and consumer electronics industries, where the push for lightweight and compact designs is leading to innovative connector solutions.

- Smart Connectivity: Integration of sensors and diagnostics features for enhanced monitoring and control. These smart connectors can provide real-time feedback on connection status, which helps in predictive maintenance and enhances overall system reliability.

- Sustainability: Use of recyclable materials and energy-efficient designs to reduce environmental impact. The growing focus on sustainability in manufacturing practices is prompting manufacturers to explore eco-friendly materials and processes in connector production.

- Advanced Manufacturing Techniques: The application of techniques such as additive manufacturing (3D printing) allows for rapid prototyping and customization of connectors, improving lead times and facilitating tailored solutions for specific applications.

- Wireless Solutions: The advent of wireless connectivity is shifting some focus away from traditional connectors, pushing the industry to innovate in developing high-performance connectors that meet the demands of modern wireless technologies.

Case Studies of PKZ Connectors in Action

Understanding how PKZ Connectors are utilized in real-world scenarios can provide deeper insights into their benefits and applications. Here are several case studies highlighting their effectiveness:

Case Study 1: Automotive Applications

In the automotive sector, a leading manufacturer faced challenges with its current wiring harness due to frequent electrical failures that resulted in costly downtime. The company opted to replace its existing connectors with PKZ Connectors specifically designed for automotive applications. These connectors provided enhanced sealing against moisture and contaminants while also improving the reliability of data transmission systems within the vehicle.

The results were significant: electrical failures were reduced by over 50%, leading to enhanced vehicle performance and increased customer satisfaction. Additionally, the programming of these connectors allowed for easier integration into the existing manufacturing flow, thus minimizing labor costs and installation time.

Case Study 2: Renewable Energy Systems

A solar energy company focused on expanding its product line for residential applications implemented PKZ Connectors in its inverter systems. Each inverter required high-durability connectors to handle the varying conditions of outdoor installations.

The PKZ Connectors provided the necessary reliability, ensuring that the system would maintain performance even under adverse weather conditions. The company reported a 30% increase in system reliability, reducing maintenance visits and associated costs while boosting the overall trust in their product line.

Case Study 3: Aerospace Industry

In the aerospace sector, a company was tasked with upgrading its avionics systems, which demanded connectors that could withstand vibrations and extreme temperatures. By integrating PKZ Connectors known for their rigorous testing and certification, the company could meet the stringent safety and performance standards required in aviation applications.

As a result, the updated connector systems reported increased durability and performance stability, leading to a successful deployment of the new avionics suite in multiple aircraft. This not only improved system performance but also provided confidence in the safety and reliability of the aircraft.

FAQs

- What industries benefit from PKZ Connectors?

Industries such as manufacturing, telecommunications, automotive, aerospace, medical, and renewable energy commonly utilize PKZ Connectors due to their reliability and versatility. They are favored wherever consistent electrical performance is critical. - Can PKZ Connectors be customized?

Yes, manufacturers often provide customization options to meet specific application needs, including bespoke configurations and materials, ensuring that these components meet unique operational demands. - How do PKZ Connectors enhance safety in electrical systems?

By ensuring secure connections and reducing the likelihood of electrical failures, PKZ Connectors enhance overall system safety and reliability. Features like improved moisture resistance and the ability to handle vibration create a safer operational environment. - What kind of testing do PKZ Connectors undergo?

PKZ Connectors are typically subjected to rigorous testing protocols to assess their performance under various conditions. This includes electrical testing, mechanical strength assessments, environmental resistance checks, and life-cycle testing to simulate years of use. - Are PKZ Connectors suitable for outdoor applications?

Yes, many PKZ Connectors are specifically designed to withstand outdoor conditions, featuring protective measures like sealed enclosures to guard against moisture, dust ingress, and severe temperature changes.

Conclusion

PKZ Connectors are integral to the efficient and safe operation of various electrical and data systems. Their robust design and versatile functionality cater to multiple industries, making them one of the critical components in modern technology solutions. As connectivity demands grow and the need for reliable, high-performance connectors becomes increasingly apparent, professionals in the industry should focus on selecting the appropriate connectors that meet their specific requirements while anticipating future advances in connectivity solutions and sustainable practices.

Moreover, staying informed about emerging industry trends and innovations related to PKZ Connectors and their applications will empower stakeholders to make educated decisions that enhance system performance and reliability. As technology continues to advance, connectors will remain at the forefront, enabling the seamless connectivity that supports our increasingly interconnected world. Adopting and maintaining PKZ Connectors contributes significantly to the reliability and performance of modern technological infrastructures, ensuring that industries can continue to innovate and excel in their respective fields.