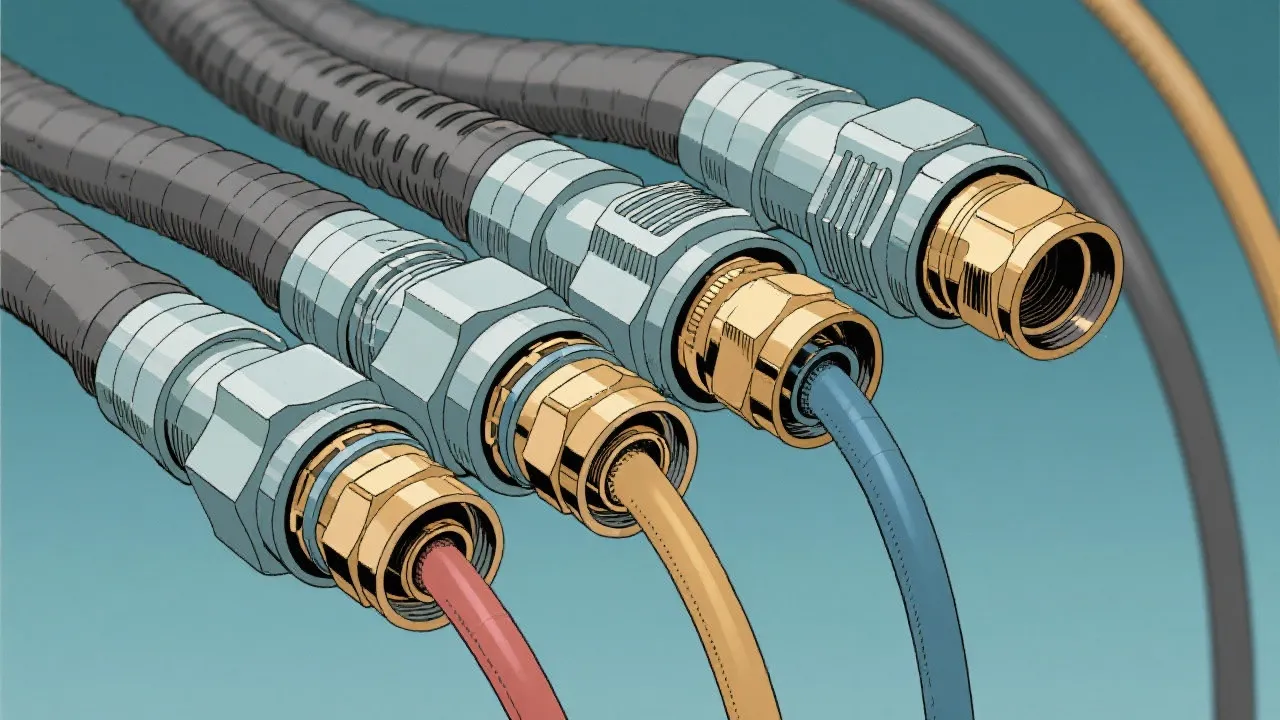

Understanding Pkz Connectors

Explore the significance of Pkz Connectors in today's industrial landscape. These essential components in electrical and electronic systems provide reliable connectivity between various devices. From automobiles to home appliances, Pkz Connectors ensure seamless operations by facilitating efficient electrical flow. Their use is critical in maintaining the integrity and functionality of complex systems across numerous sectors.

Introduction to Pkz Connectors

In modern industries, Pkz Connectors play a pivotal role in enabling and maintaining electrical connections across a plethora of applications. These connectors are crucial, providing robust and reliable connectivity solutions in diverse sectors such as automotive, aerospace, telecommunications, and consumer electronics. The intricate design and engineering of Pkz Connectors cater not only to performance but also to safety and efficiency.

Historical Background of Electrical Connectors

The evolution of electrical connectors can be traced back to the early days of electricity usage. As electrical systems became more complex, the need for reliable and efficient connectivity solutions gave birth to various types of connectors. Pkz Connectors are a part of this evolution, representing a sophisticated development tailored to meet modern electrical demands. Their design and functionality reflect more than just an industrial need; they embody years of technological progression and a deep understanding of electrical engineering. The introduction of Pkz Connectors amidst this historical backdrop showcases how industries have been continuously striving to improve connectivity for enhanced performance.

Why Pkz Connectors are Essential

Pkz Connectors stand out for their versatility and reliability. Designed to offer seamless connectivity, they are integral to various systems where maintaining unbroken electrical flow is paramount. In automobiles, for instance, Pkz Connectors ensure the effective integration of electronic control units, power distribution, and safety systems. This is crucial as modern vehicles rely heavily on electronic systems to manage performance and safety features. Similarly, in telecommunications, they facilitate the rapid transmission of data without loss or interference, which is vital in a world increasingly reliant on fast internet communication and data services.

Applications of Pkz Connectors

- Automotive Industry: Used extensively in vehicle electronics, ensuring connectivity between different modules such as navigation systems, lighting, and engine management. The automotive sector has seen a notable shift towards more electronic features, with Pkz Connectors playing a central role in their functionality. From infotainment systems to advanced driver-assistance systems (ADAS), reliable connectors form the backbone of digital innovations in vehicles.

- Consumer Electronics: Facilitate reliable connections in gadgets, ensuring devices function optimally and efficiently. As consumer electronics evolve, the demand for compact and efficient connectors rises. Pkz Connectors can be found in smartphones, tablets, and wearable technology, where space limitations require innovative design solutions to maintain performance without compromising quality.

- Telecommunications: Provide robust solutions for data and signal transmission across networks. Pkz Connectors are critical in the construction of data centers and communication networks, where efficient signal transfer is crucial to preventing data loss and ensuring robust connectivity for an ever-increasing number of users.

- Industrial Machinery: Ensure seamless operation and integration of complex machinery systems. In manufacturing plants, Pkz Connectors allow different machines and systems to communicate reliably. This interconnectivity is essential for automation processes and the smooth flow of production lines.

- Aerospace Applications: Pkz Connectors are utilized in aircraft wiring, as they are designed to withstand extreme temperatures and harsh environmental conditions. The reliability and precision of these connectors are vital for maintaining communication and control systems in aircraft, where safety is paramount.

The Technical Aspects of Pkz Connectors

The technical ingenuity behind Pkz Connectors lies in their design, which allows them to efficiently handle electrical loads, provide insulation, and offer resistance to environmental factors. These connectors are designed to reduce the impact of environmental stressors such as vibration, dust, humidity, and temperature variations, making them suitable for a wide range of applications. Notable features of Pkz Connectors include:

- Material Composition: Pkz Connectors are often made from high-strength materials that ensure durability and reliability. Materials like reinforced plastics and corrosion-resistant metals provide longevity, even in challenging environments.

- Electrical Characteristics: The design of these connectors ensures optimal electrical performance, meaning they can handle high current loads and have minimal power loss or voltage drop across connections.

- Environmental Sealing: Many Pkz Connectors come with sealing features that protect against moisture and dust ingress, thus ensuring a reliable connection in outdoor or industrial settings where exposure to harsh environments is common.

- Ease of Installation: The design of Pkz Connectors simplifies installation processes, reducing assembly time and minimizing the chance of installation errors. Features such as color-coded pins and built-in guides assist engineers in correctly aligning components.

Quality and Standards

The manufacturing of Pkz Connectors involves stringent quality control measures to ensure they meet international standards for safety and performance. These standards govern their use in critical applications, where any failure could lead to substantial repercussions. Compliance with standards such as ISO 9001 and IEC 60512 ensures that Pkz Connectors are subjected to rigorous testing procedures that assess their durability, reliability, and overall performance. Manufacturers often conduct tests covering a range of parameters, including:

- Electrical Testing: This encompasses tests for current carrying capacity, voltage drop, and insulation resistance to guarantee the connectors function as intended without overheating or causing circuit failure.

- Mechanical Testing: Connectors are subjected to mechanical stress tests, including vibration, shock, and pull tests, to simulate real-world conditions and ensure that the connectors can withstand movement and stress over their operational lifespan.

- Environmental Testing: Pkz Connectors are evaluated under various environmental conditions, including humidity, temperature extremes, and exposure to chemicals, to ensure they perform reliably regardless of the circumstances.

Comparative Analysis of Pkz Connectors

| Connector Type | Performance | Applications |

|---|---|---|

| Standard PKZ | High reliability, moderate load capacity | General purpose, consumer electronics |

| Heavy-duty PKZ | Extremely robust, high load capacity | Industrial machinery, automotive |

| Miniature PKZ | Compact, efficient for tight spaces | Wearable technology, compact electronics |

| High-Speed PKZ | Enhanced data transmission efficiency | Telecommunications, networking equipment |

| Adaptable PKZ | Versatile fittings for various configurations | Custom applications, modular systems |

Future Trends in Pkz Connectors

The future of Pkz Connectors is steering towards innovation driven by advancements in technology and materials. The integration of smart technologies is one area where these connectors are expected to evolve, offering enhanced diagnostic capabilities and remote management features. This can optimize performance monitoring and aid in predictive maintenance, thereby reducing downtime caused by unexpected failures.

Moreover, the push for sustainability is likely to influence the materials and manufacturing processes involved. As industries recognize their environmental impact, there is a growing focus on creating connectors from eco-friendly materials without compromising performance reliability. This green initiative is not only beneficial for the environment but can also appeal to a market segment increasingly concerned about sustainable practices.

Additionally, advancements in manufacturing techniques like 3D printing may introduce new design possibilities, enabling manufacturers to create customized and lightweight Pkz Connectors tailored to specific applications. The rapid expansion of the Internet of Things (IoT) and smart devices will continuously drive the need for efficient, high-performance connectors to facilitate seamless connectivity across a multitude of devices.

Maintenance and Care for Pkz Connectors

Ensuring the longevity and reliability of Pkz Connectors is paramount in any application. Regular maintenance and care can significantly extend the life of connectors and prevent performance issues. Here are some essential practices to follow:

- Regular Inspection: Periodically inspect connected systems for signs of wear, corrosion, or damage. Early detection of issues can help prevent sudden failures.

- Cleaning: Keep connectors free from dust, dirt, and contaminants. Depending on the environment, connectors may require cleaning with suitable solvents to maintain a reliable connection.

- Testing: Utilize testing equipment to check electrical parameters like resistance, capacitance, and signal quality. Regular testing can help identify potential problems before they lead to failures.

- Temperature Management: Monitor operating temperatures, especially in high-load applications. Ensure connectors are used within recommended temperature ranges to prevent overheating.

- Environment Awareness: Be aware of environmental factors affecting connectors, such as humidity, vibration, and exposure to chemicals. Using connectors with suitable resistance to these conditions can greatly enhance reliability.

FAQs

- What makes Pkz Connectors preferable over other types?

Pkz Connectors are engineered for reliability, efficient connectivity, and resistance to environmental stress, making them ideal for crucial applications. - Can Pkz Connectors be customized?

Yes, many manufacturers offer customization options to cater to specific needs and applications, ensuring optimal performance. - How are Pkz Connectors tested for quality?

They undergo rigorous testing to meet international standards for electrical performance, durability, and safety. - What are the signs of a failing Pkz Connector?

Common signs include intermittent connectivity, visible corrosion, physical damage, and abnormal heating during operation. - Are Pkz Connectors suitable for outdoor applications?

Many Pkz Connectors are designed with environmental sealing features that make them suitable for outdoor use. However, specific designs should be selected based on environmental conditions. - Can Pkz Connectors withstand extreme temperatures?

Yes, certain Pkz Connectors are designed to operate effectively within a broad temperature range, making them suitable for applications in extreme environments.

As industries continue to evolve, the role of Pkz Connectors becomes increasingly vital. Their adaptability and robust performance make them indispensable in maintaining the integrity of complex systems, paving the way for future technological advancements. Pkz Connectors are not merely components; they serve as a foundation for the reliable electrical infrastructure upon which modern technology relies, ensuring seamless integration across various applications. With ongoing innovations, manufacturers will continue to explore new functionalities and designs, ensuring these connectors remain a vital component of future electrical systems.