Understanding Caterpillar Injector Systems

Caterpillar injectors are crucial components in heavy machinery engines, ensuring efficient fuel delivery and optimal performance. These injectors are known for their durability and precision, contributing significantly to the effectiveness of Caterpillar's hydraulic excavators, diesel generators, and other machinery. This article explores their importance, functionality, and the technological advancements that continue to enhance their role in the heavy machinery industry.

The Role and Importance of Caterpillar Injectors

Caterpillar injectors play a pivotal role in the functionality of heavy machinery by administering precise amounts of fuel to the engine cylinders, ensuring optimal combustion and performance. These injectors are integral to the operation of various Caterpillar machines, including hydraulic excavators and diesel generators, both renowned for their durability and efficiency. The injectors not only influence performance metrics but are also critical in managing emissions, making them essential in today’s environmentally conscious market.

Due to the extensive use of these machines in construction, mining, agriculture, and industrial applications, the reliability of Caterpillar injectors directly impacts productivity. Any malfunction can lead to significant downtime, which can be costly for operators. Therefore, understanding the importance of these small but mighty components can lead to better maintenance strategies and operations overall.

How Caterpillar Injectors Work

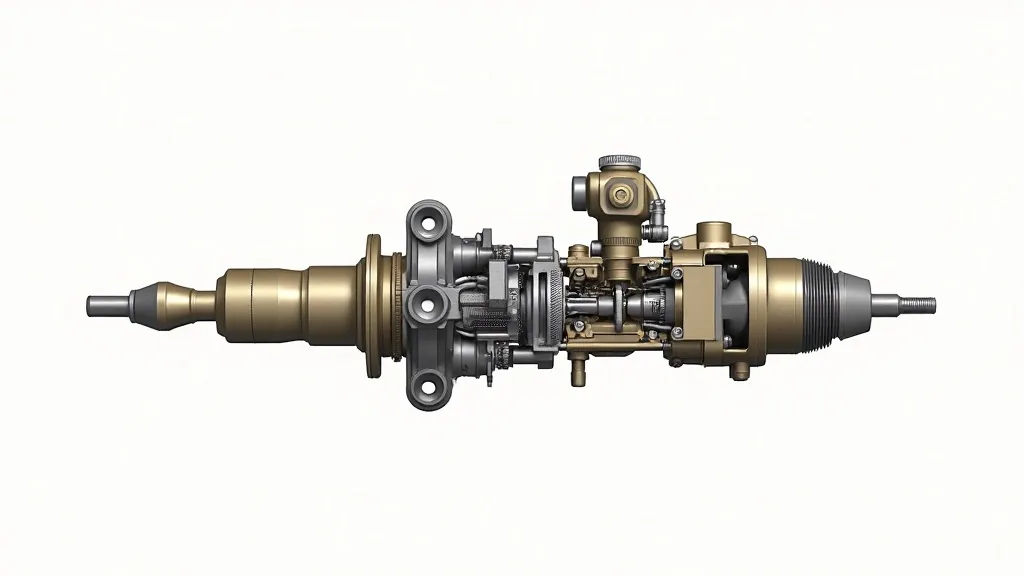

At the core of its operation, a Caterpillar injector delivers fuel into the engine under high pressure, which allows for the fine misting necessary for efficient combustion. This precision delivery system helps maximize engine performance, reduce emissions, and improve fuel efficiency. The injectors are designed to withstand extensive wear and tear from prolonged use in heavy-duty machinery. They operate using a process called direct injection, where fuel is injected directly into the combustion chamber rather than into the intake manifold.

This method allows for better control of the combustion process, leading to more complete fuel burning and reduced residues. The injectors achieve this by using a series of needles, springs, and solenoids that respond to various engine conditions as dictated by an electronic control unit (ECU). As engine demands change with operating conditions—like engine speed and load—the ECU adjusts the timing and quantity of the fuel injected, resulting in optimized combustion efficiency.

Technological Advancements in Caterpillar Injectors

Over the years, Caterpillar has continued to innovate its injector technology. Recent advancements include improved materials for enhanced durability, electronic control systems for better precision, and the integration of more comprehensive diagnostic capabilities. These enhancements aim to minimize downtime and extend the operational life of the injectors, which translates to more cost-effective maintenance and repairs for machinery operators.

One notable advancement has been the shift from traditional mechanical injectors to electronically controlled injectors. Electronic injectors provide greater accuracy in fuel delivery, allowing for multiple injection events during a single combustion cycle, known as pilot injection. This capability improves cold start performance, reduces noise, and lowers emissions significantly.

Another technological development has been the use of advanced fuel filtration systems that ensure cleaner fuel reaches the injectors. Contaminated fuel is a primary cause of injector failure, and improved filtration helps maintain the integrity and functionality of the injectors, thus prolonging their lifespan.

Choosing the Right Caterpillar Injector

When selecting a Caterpillar injector, consider the specific needs of your machinery. Factors such as engine type, model number, and intended operational load all play a role in determining the very suitable injector. Caterpillar’s catalog includes a variety of injectors compatible with different machines, each designed to meet specific performance criteria.

Compatibility is crucial, as using an injector that does not match your engine can lead to inefficient fuel combustion, increased emissions, and ultimately could damage engine components. It is advisable to consult the machine's manual or engage with a Caterpillar dealer to ensure the injector choice aligns perfectly with your equipment’s specifications.

| Injector Model | Application | Key Features |

|---|---|---|

| C7/C9 Common Rail Injector | Hydraulic Excavators | High precision, reduced emissions |

| 320D2 Injector | Diesel Generators | Enhanced durability, electronic control |

| 3116 Injector | Marine Engines | Corrosion resistance, high-pressure capability |

| 3406E Injector | Trucks and Buses | Agile fueling, performance scaling |

Troubleshooting and Maintenance Tips

Even with advanced technology, Caterpillar injectors can experience issues that may affect engine performance. Common signs of injector problems include reduced engine power, increased fuel consumption, and irregular emissions. Regular maintenance checks and using diagnostic tools can help identify and resolve these issues promptly. It's also advisable to follow Caterpillar's guidelines for injector care and replacement intervals to prevent unexpected breakdowns.

Routine inspections are essential for maintaining injector performance. This includes checking for any signs of leakage around the injectors, as well as ensuring that fuel filters are clean and functioning correctly. Additionally, using high-quality fuel can minimize the risk of injector clogging. Modern injectors are highly sensitive, and contaminants can severely impact their performance.

If you experience injector-related issues, it is beneficial to utilize diagnostic equipment capable of reading fault codes from the engine's ECU. These codes can provide insights into the health of the injectors and other engine components. Identifying issues early can prevent more severe damage and costly repairs.

FAQs

- What are the signs of a faulty Caterpillar injector? Key indicators include engine misfires, irregular idling, increased fuel consumption, and a noticeable drop in engine power output.

- How often should Caterpillar injectors be replaced? Injector replacement is generally recommended based on operational hours and manufacturer guidelines, typically around 100,000 to 150,000 miles for heavy machinery. However, if you notice performance issues sooner, it may be wise to inspect them immediately.

- Can I repair a Caterpillar injector myself? While some issues can be resolved with basic mechanical skills, it is often best to consult with a certified Caterpillar technician for complex repairs or replacements to ensure accurate diagnostics and quality parts.

- What should I do if I suspect an injector issue? It is advisable to conduct a diagnostic check using appropriate tools and to consult your machine's manual. If necessary, engage a professional technician for a thorough inspection and repair.

- Are there aftermarket injectors available? While several aftermarket injectors may fit, it’s crucial to ensure they meet Caterpillar's quality standards, as inferior products can lead to further engine problems and void warranties.

The Importance of Preventive Maintenance

Understanding the role of preventive maintenance in sustaining the efficiency of Caterpillar injectors is crucial for any operator. Just like any other component of a heavy machine, injectors require regular check-ups and maintenance to function optimally. Preventive maintenance not only extends the life of the injectors but also enhances the overall performance and reliability of the machinery.

This promotes a culture of care and precision among operators and technicians alike. Some best practices include:

- Consistent monitoring of fuel quality to avoid contamination that could harm injectors.

- Routine checks of fuel filters to ensure they are not clogged or degraded.

- Regular engine diagnostic scans to catch potential issues early.

- Adhering to a maintenance schedule that aligns with the manufacturer's recommendations.

Real-World Applications and Case Studies

Caterpillar injectors are not only vital for the machinery itself but also for the industries that rely on them. Let’s delve into a few real-world applications and case studies that illustrate the significance of injectors in various settings.

Construction and Excavation

In the construction sector, the efficiency of heavy machinery directly correlates with project timelines and operational costs. A construction company working with Caterpillar hydraulic excavators noticed significant fuel wastage and performance drops due to injector malfunctions. By investing in precision injectors and establishing a routine maintenance protocol, the company reduced fuel consumption by 15% and increased machine availability, which ultimately led to completing projects ahead of schedule.

Agriculture

In agriculture, where every hour of machine downtime can result in lost yield, injector performance is paramount. A farm specializing in large-scale crop production found that using high-quality Caterpillar injectors with improved diagnostic capabilities enabled them to optimize their fuel usage during planting. This adjustment not only improved yield outcomes by ensuring power was utilized efficiently but also provided notable savings during the fuel budgeting period.

Marine Operations

In marine applications, reliability is critical, given the harsh conditions and high operational demands. A fishing company operating boats powered by Caterpillar 3116 marine engines implemented a comprehensive injector maintenance program. Regular diagnostics and timely replacements minimized unexpected failures, enabling them to meet their operational schedule and enhancing fuel efficiency. The result was not just cost savings but also improved compliance with emissions regulations.

Future Prospects for Caterpillar Injectors

As industries continue to evolve and shift towards eco-friendliness, the future of Caterpillar injectors will likely incorporate new technologies that focus on sustainability. Innovations may include increased integration with hybrid and electric powertrains, where injectors will play a crucial role in blending different fuel sources effectively.

Advancements in computer modeling and artificial intelligence may also enable the development of injectors that can adapt in real-time to changing conditions within the engine. This level of sophistication can lead to further reductions in emissions and enhanced efficiency, supporting global efforts toward cleaner waste management and operational protocols.

Moreover, as governments worldwide implement stricter emission standards, Caterpillar injectors will likely evolve to comply with these regulations. Ongoing research and development in fuel types could see the emergence of injectors specifically designed to work with alternative fuels, further increasing the relevance of Caterpillar machinery in an expanding market.

Conclusion

In conclusion, Caterpillar injectors are essential for the efficient operation of heavy-duty machinery. Understanding their functionality, choosing the right model, and implementing a robust maintenance routine can significantly improve your equipment's performance and longevity, ensuring that your investment in Caterpillar machinery is well protected.

As industries grow increasingly reliant on advanced machinery, the pivotal role of components like injectors becomes ever clearer. Their continuous technological evolution and the necessity for meticulous maintenance will define the future of heavy machinery's operational success.