Understanding the Garwin G450 Vacuum Pump

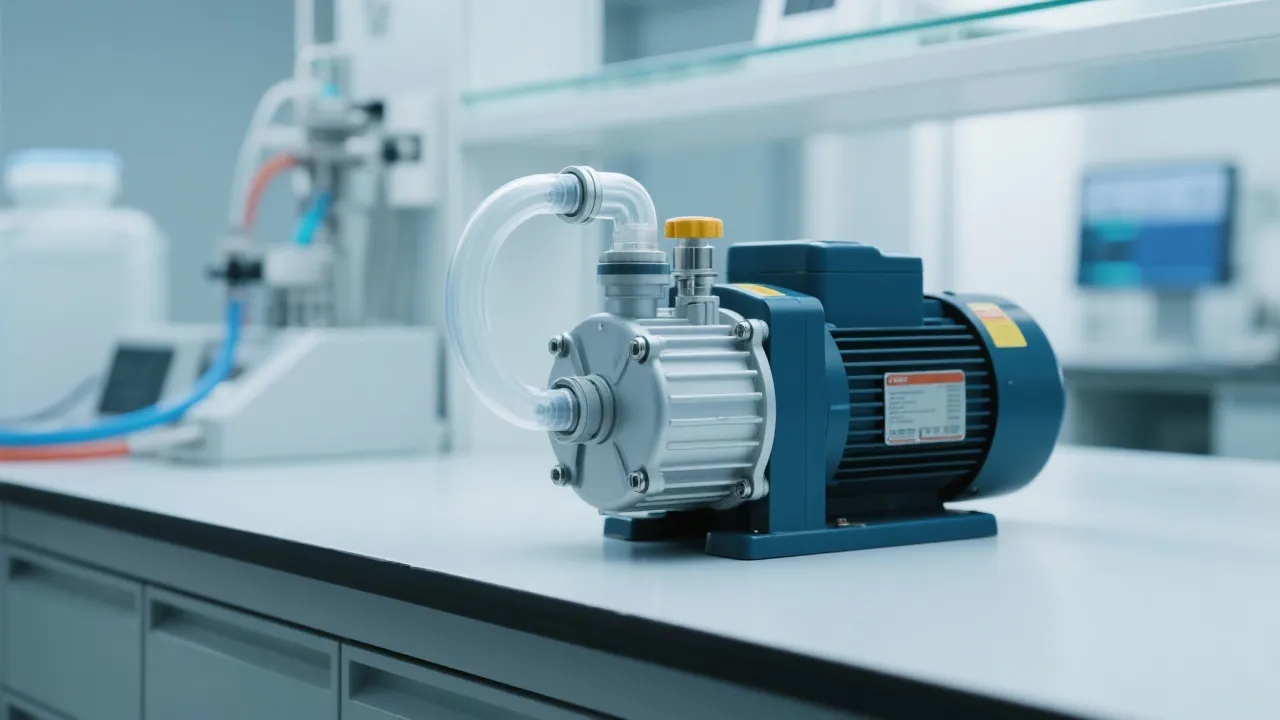

The Garwin G450 Vacuum Pump represents a sophisticated solution in vacuum technology. Known for its robust performance, the Garwin G450 is designed for a variety of applications requiring precise control of pressure and flow within vacuum systems. This article delves into the features, benefits, and applications of the Garwin G450, offering insights from industry experts to guide potential users in their decisions.

An Introduction to Vacuum Technology

Vacuum technology plays a crucial role across a multitude of industries, from healthcare to aerospace engineering. Equipment like vacuum pumps is essential in creating environments necessary for manufacturing, research, and quality control processes. Among the notable innovations in this field is the Garwin G450 Vacuum Pump, a device engineered for efficiency and reliability. This advanced piece of equipment not only contributes to the optimization of processes but also ensures that products meet the stringent quality control standards imposed by various industries.

Essential Elements of Vacuum Technology

To appreciate the significance of vacuum technology, it is important to understand its foundational elements. A vacuum is defined as a space devoid of matter, including air, which allows for the manipulation of materials in a controlled manner. By reducing pressure within a chamber, vacuum technology enables processes like distillation, freeze-drying, and chemical vapor deposition to be performed more effectively. This manipulation can result in purer substances, higher yields, and the ability to carry out reactions that would be impossible under atmospheric conditions.

Features of the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is celebrated for its advanced engineering and design, capable of maintaining stable vacuum conditions in demanding environments. Its robust construction ensures durability and longevity, making it a preferred choice for industries that cannot compromise on reliability. This pump excels in providing consistent performance under continuous operation, minimizing downtime and maintenance costs. Key features of the Garwin G450 include a sophisticated motor design that improves energy efficiency, a vibration-damping mounting mechanism, and built-in data logging systems for real-time performance monitoring.

Benefits of Using Garwin G450

- Efficiency: The pump is designed for high capacity and energy efficiency, which can significantly reduce operational costs. The integration of advanced technology allows for energy savings without sacrificing performance.

- Precision: Its ability to finely control vacuum pressure makes it ideal for sensitive applications such as semiconductor manufacturing and pharmaceuticals. This precision ensures that the processes yield predictable and repeatable results.

- Durability: With superior build quality, the Garwin G450 offers a long lifespan even in rugged use cases. This durability translates into lower total cost of ownership since replacements and extensive maintenance are minimized.

- Noise Reduction: The design of the Garwin G450 includes features that reduce operational noise, making it suitable for environments where noise levels need to be kept to a minimum, such as laboratories and medical facilities.

- Compact Design: Despite its robust capabilities, the Garwin G450 maintains a compact design that allows for easy installation in various setups, optimizing space utilization.

Applications of the Garwin G450 Vacuum Pump

From use in laboratories to integration in manufacturing processes, the Garwin G450 is versatile enough for a wide array of applications. It is particularly beneficial in settings that require meticulous control of vacuum conditions, such as in chemical processing, food packaging industries, and in the production of electronic components. For instance, in the pharmaceutical industry, the Garwin G450 is often used for lyophilization, a process that involves freeze-drying drugs. This requires precise vacuum control to ensure the integrity and effectiveness of the pharmaceutical products.

In the food packaging industry, vacuum pumps are essential for extending the shelf life of products by removing air and inhibiting the growth of bacteria, thus maintaining product quality. The Garwin G450 is engineered to handle varying demands across different processes, making it an ideal choice for food packagers looking to innovate their preservation techniques. It can also be utilized in the manufacturing of composites and in vacuum-assisted resin transfer molding (VARTM), a technique commonly used in aerospace engineering to create lightweight and strong materials.

Insights from Industry Experts

Experts in vacuum technology herald the Garwin G450 for its ability to balance high performance with energy conservation. They note the importance of its reliability in environments where maintaining a consistent vacuum is critical. Additionally, its user-friendly interface allows for intuitive operation and quick troubleshooting. Such ease of use is vital in an industrial setup where time is often a critical factor. Moreover, many industry professionals highlight the pump’s adaptability across various settings, from laboratory environments to heavy manufacturing units.

Comparison Table: Garwin G450 vs. Other Models

| Feature | Garwin G450 | Other Models |

|---|---|---|

| Max Capacity | High | Variable |

| Energy Efficiency | Optimized | Standard |

| Durability | Long-lasting | Average |

| No Noise Level | Low | Moderate |

| Weight | Lightweight | Heavy |

| User Interface | Intuitive | Complex |

FAQs

- What industries benefit from the Garwin G450?

- This vacuum pump is ideal for industries such as pharmaceuticals, semiconductor manufacturing, and food packaging that require precise vacuum control. Its versatility allows it to adapt to various applications, making it a go-to choice in multiple sectors.

- Is the Garwin G450 easy to maintain?

- Yes, it is designed for straightforward maintenance with easy access to key components, minimizing downtime. Regular checks can be performed without using specialized tools, allowing operators to maintain the pump efficiently.

- What is the warranty period for the Garwin G450?

- The Garwin G450 typically comes with a two-year warranty, covering manufacturing defects and performance issues, backing the reliability of this advanced vacuum pump.

- How does the Garwin G450 compare in terms of energy usage?

- The Garwin G450 is designed to consume less energy compared to other models, which can lead to considerable savings in operational costs over time, making it an environmentally friendly option.

- Can the Garwin G450 be customized for specific applications?

- Yes, certain adaptations can be made to the Garwin G450 to meet the unique requirements of specific industrial uses, thereby enhancing versatility and functionality.

The Future of Vacuum Technology

The field of vacuum technology continues to evolve, incorporating advances in materials science, automation, and control systems. Manufacturers are increasingly focused on improving efficiencies and reducing their environmental impact. Future developments may include the integration of IoT (Internet of Things) technology, which would allow for real-time monitoring and diagnostics. Such advancements could not only enhance the performance of vacuum systems like the Garwin G450 but also optimize their operation to further reduce energy consumption.

The expansion of applications into newer fields such as nanotechnology and environmental sciences also suggests that vacuum pumps will play an even more critical role in future innovations. Furthermore, the ongoing need for cleanroom environments in various industries, especially in pharmaceuticals and electronics, suggests that demand for high-performance vacuum systems will only continue to grow.

Conclusion

The Garwin G450 Vacuum Pump stands out for its combination of efficiency, precision, and durability, making it a valuable asset for any industry relying on advanced vacuum technology. The pump's robust features and adaptability meet the diverse needs of users in different sectors. For those seeking to enhance their operational capabilities, this pump is an investment worth considering. Adopting the Garwin G450 not only positions companies for enhanced performance but also embraces a commitment to quality, efficiency, and sustainability in today's competitive industrial landscape. As industries evolve, the Garwin G450 exemplifies the type of innovative technology that will shape the future of vacuum processes.