The Garwin G450 Vacuum Pump Revolution

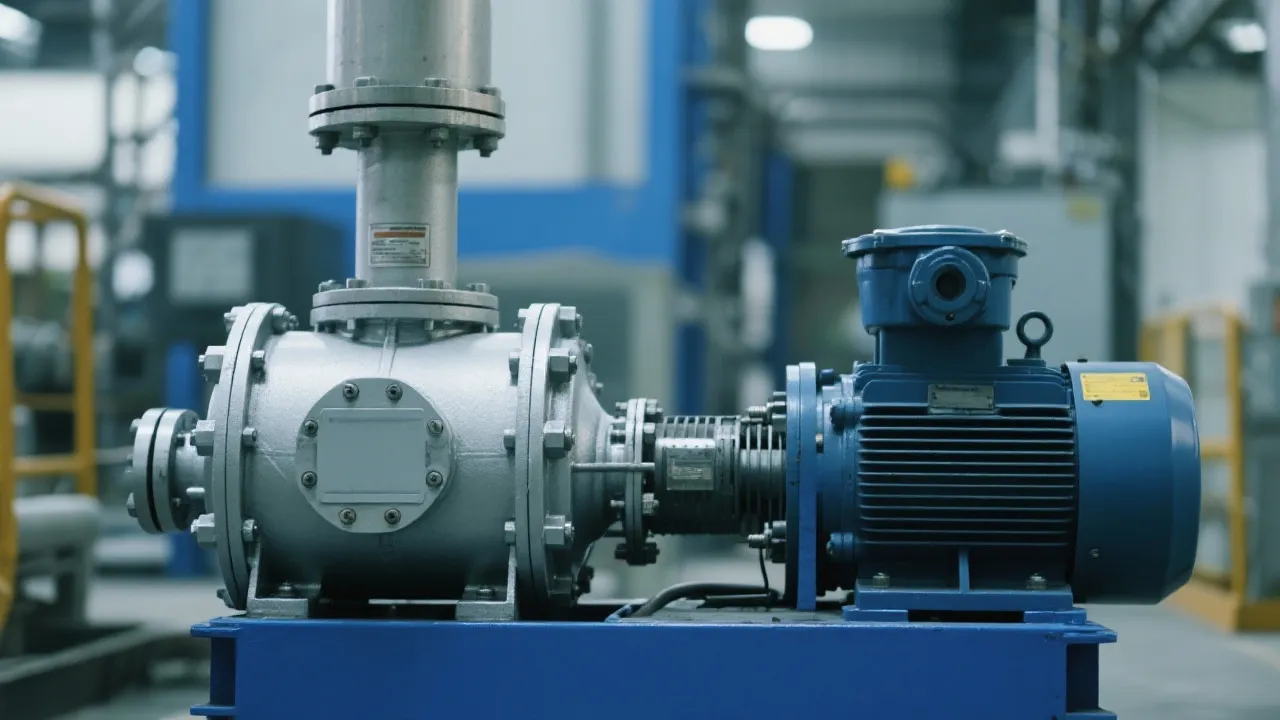

The Garwin G450 Vacuum Pump stands as a pivotal tool in the machinery sector, excelling in various industrial applications. Known for its efficiency and reliability, this vacuum pump caters to diverse industries such as manufacturing, pharmaceuticals, and automotive. The device's superior engineering ensures optimal performance, making it a preferred choice for businesses seeking advanced vacuum solutions.

Introduction to the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is a marvel of engineering, catering to a wide range of industrial needs. This heavy-duty machinery plays a critical role in maintaining operations in sectors such as manufacturing, pharmaceuticals, and automotive industries. Known for its uncompromised performance, the Garwin G450 is designed to provide enhanced vacuum capabilities, ensuring maximum industrial efficiency and productivity. The significance of vacuum technology in contemporary industrial operations cannot be understated, as it serves as the backbone for various processes, from material handling to precision assembly.

Features and Technical Specifications

At the heart of its impressive performance are the features and specifications that define the Garwin G450. This vacuum pump boasts a robust build, crafted with materials that promise durability and longevity. Its high-performance motor enables efficient suction, critical for various applications requiring vacuum technology. The pump's precision engineering minimizes energy consumption while maximizing output, setting a benchmark in industrial standards. Some additional specifications contribute to the overall efficiency of the Garwin G450:

- Maximum Pressure: Can achieve a pressure of up to 10^-3 mbar, making it suited for deep vacuum applications.

- Pumping Speed: Features an impressive pumping speed of 450 m³/h, ensuring rapid evacuation of air and gases.

- Weight: Its robust design weighs approximately 120 kg, providing stability during operation.

- Noise Level: Operates within a sound level of just 65 dB, which is significantly quieter than many competing models.

- Dimensions: Compact dimensions (90 cm x 60 cm x 40 cm) allow for easy integration into existing setups.

Applications Across Industries

One of the key reasons the Garwin G450 is highly sought after is its versatility. In the manufacturing sector, it supports processes that require clean environments, such as semiconductor production and plastics. The pharmaceutical industry benefits from its reliability in maintaining sterile conditions. Automotive sectors depend on it for processes that demand exacting precision. Its application extends to any industry where vacuum technology is imperative.

In the food processing industry, for example, the Garwin G450 is employed for vacuum packing foods to extend shelf life while preserving flavor and nutritional value. Similarly, in the environmental sector, it is utilized for vacuum filtration, allowing for the effective separation of liquids from solids. The medical industry also benefits from the Garwin G450, which is critical for suction devices and laboratory processes, further demonstrating its adaptability across various fields.

Comprehensive User Guide

Operating the Garwin G450 Vacuum Pump efficiently requires understanding its mechanism and top practices. Here's a step-by-step guide:

- Installation: Secure the pump on a flat, sturdy surface to minimize vibrations. Ensure the surrounding area is free from debris and obstacles that could impede airflow. It's crucial to install it in a well-ventilated area to allow for effective cooling during operation.

- Connection: Properly connect the hoses and power source, following the manual's protocols to avoid mishaps. Always use high-quality, compatible hoses to prevent leaks and ensure the integrity of the vacuum.

- Operation: Gradually power up the pump. Monitor its performance through the integrated control panel, adjusting pressure levels as necessary for specific tasks. Familiarize yourself with the various settings, including the adjustable speed control, to personalize the operation based on the application at hand.

- Maintenance: Regularly check for wear and tear. Lubricate moving parts according to the schedule recommended in the manual. Additionally, regularly inspect the filters and replace them if necessary to maintain optimal performance.

Maintenance Best Practices

Proper maintenance is essential to prolong the lifespan of the Garwin G450 and keep it operating at peak efficiency. Here are several best practices to consider:

- Routine Checks: Schedule weekly or bi-weekly checks to ensure that all parts are functioning correctly, focusing on belts, seals, and electrical connections.

- Cleaning: Ensure that the exterior and surrounding areas are clean. Dust and debris can interfere with the pump's operation and lead to overheating.

- Fluid Replacement: Certain components may require fluid replacements. Always refer back to the manufacturer's guidelines for specifics on types and replacement frequency.

- Calibration: Periodically calibrate the pressure readings with a reliable gauge to ensure accuracy in production processes.

Comparison Table: Why Choose Garwin G450?

| Feature | Garwin G450 | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Medium | Medium |

| Energy Efficiency | Optimal | Sub-optimal | Moderate |

| Applications | Versatile | Limited | Moderate |

| Price Range | Competitive | High | Moderate |

Procurement and Supplier Information

When considering acquiring a Garwin G450 Vacuum Pump, businesses should consider reliable suppliers who offer comprehensive support services. It's advisable to work with vendors that provide full installation support, ongoing maintenance, and technical assistance to ensure seamless integration into existing systems.

Additionally, potential buyers should compare warranty offers as these can significantly impact long-term satisfaction. A good warranty can cover defects and performance issues while reassuring businesses regarding their investment in high-quality equipment. Suppliers may also provide training for staff to ensure they are familiar with the operation and maintenance of the pump, thus enhancing productivity and reducing the likelihood of operational errors.

Cost-Effectiveness of the Garwin G450

Investing in the Garwin G450 Vacuum Pump may require a significant initial expenditure; however, its long-term benefits highlight its cost-effectiveness. The pump's energy efficiency translates into lower operational costs since it uses less power to achieve the desired vacuum levels compared to many of its competitors. Furthermore, its durability means fewer replacements and repairs over time.

A critical factor in cost-effectiveness is its reduced downtime. The Garwin G450 is engineered to perform continuously under heavy loads without overheating or breaking down, which can be detrimental in environments that depend on high-volume production. Companies can expect consistent outputs and high operational efficiency, allowing them to meet demanding production deadlines and stay competitive in their respective markets.

FAQs

- What industries benefit the most from the Garwin G450?

Industries such as manufacturing, pharmaceuticals, automotive, food processing, and environmental services greatly benefit from its advanced features.

- Is the Garwin G450 energy efficient?

Yes, it is designed to minimize energy consumption while maximizing performance, making it an energy-efficient choice for businesses looking to reduce operational costs.

- How does the Garwin G450 differ from its competitors?

Its robust construction, versatile applications, optimized energy use, and competitive pricing set it apart from many other pumps in the market.

- How often should maintenance be performed on the Garwin G450?

Routine maintenance checks should ideally be conducted weekly, with comprehensive service evaluations performed quarterly to ensure all components remain in top working condition.

- Can the Garwin G450 be used in cleanroom environments?

Yes, the Garwin G450 is designed to operate in cleanroom settings, making it suitable for applications in semiconductor and pharmaceutical manufacturing where air purity is crucial.

- What is the warranty period for the Garwin G450?

Typically, the Garwin G450 comes with a standard warranty of five years, covering defects in material or workmanship, but this may vary by supplier.

Conclusion

The Garwin G450 Vacuum Pump stands out as a cornerstone piece of equipment for industries requiring efficient vacuum technology solutions. Its powerful performance, adaptability to various tasks, and durable build make it a wise investment for companies looking to enhance their operational capabilities. By choosing the Garwin G450, businesses are assured a return on investment through high operational efficiency, reduced downtime, and enhanced productivity.

Furthermore, the support offered by competent suppliers maximizes the value a company gets from their purchase. The combination of an extensive service network, maintenance options, and training provides businesses with everything necessary to integrate the Garwin G450 into their operations effectively. In a landscape where industrial needs are constantly evolving, the Garwin G450 remains a reliable option for businesses seeking to adopt best practices and improve their operational workflows. As various sectors continue to embrace advancements in technology, the Garwin G450 Vacuum Pump exemplifies the perfect blend of performance, durability, and cost efficiency, making it an essential tool for future-forward enterprises.