The Versatility of Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump offers remarkable functionality in industrial applications. Primarily known for its efficiency, this vacuum pump stands out in various industries requiring reliable suction and pressure management. Experts recommend the Garwin G450 for its robust engineering and adaptability within diverse operational settings, making it a critical tool for ensuring smooth industrial processes.

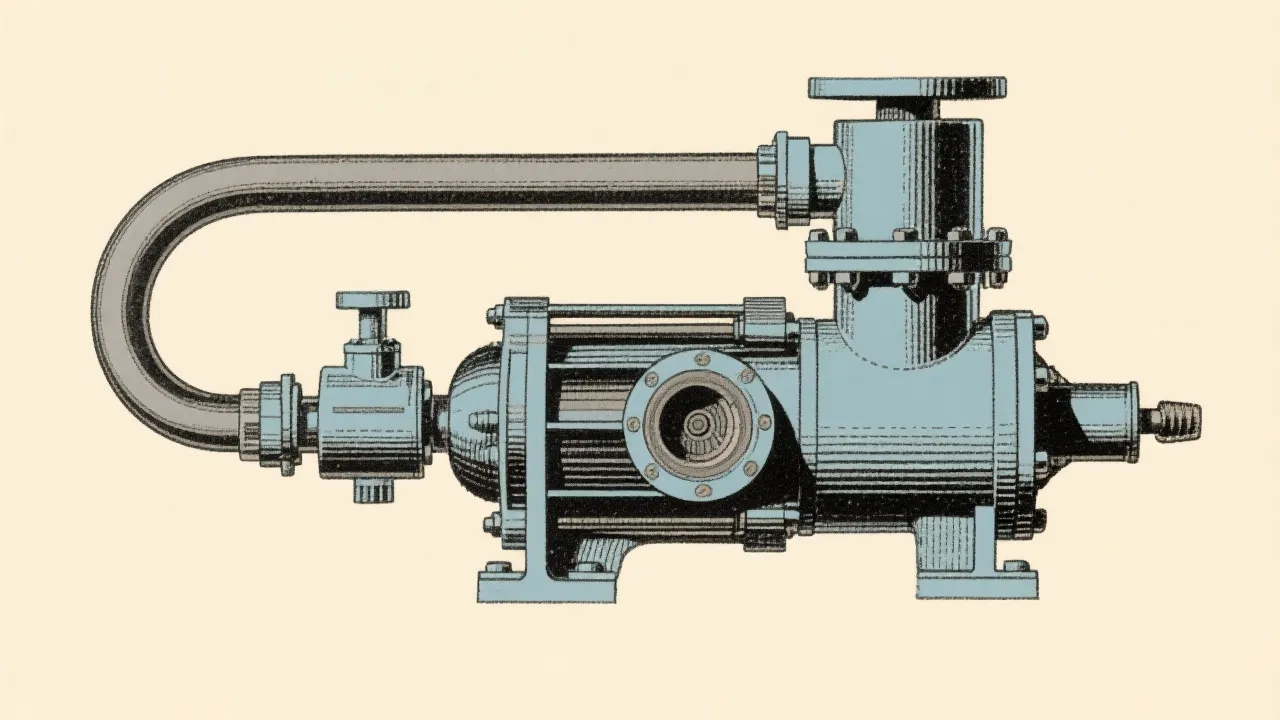

Understanding the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is a cornerstone of industrial equipment designed to handle various vacuum applications efficiently. It is well-regarded for its outstanding performance, durability, and versatility across different settings. Vacuum pumps like the Garwin G450 play a crucial role in maintaining pressure levels and facilitating the movement of fluids and gases in multiple industrial processes, underscoring their importance in today's technologically driven economy. As industries evolve with technological advancements, the role of vacuum pumps has expanded significantly, influencing numerous sectors such as pharmaceuticals, food production, chemical processes, and material sciences.

Core Features and Benefits

The Garwin G450 boasts an array of features catering specifically to the needs of industrial users. Its high pumping speed and the capability of achieving a deep vacuum make it suitable for processes that demand precision. Additionally, its design focuses on energy efficiency, which helps reduce operational costs. The reliability of the Garwin G450 ensures minimal downtime, maximizing productivity. Furthermore, the G450’s ease of operation and simple maintenance regime adds to its appeal, making it user-friendly for technicians and operators alike. In an age where operational efficiency directly correlates with profitability, the Garwin G450 stands out by streamlining processes significantly.

| Feature | Benefit |

|---|---|

| High Pumping Speed | Increases the efficiency of vacuum processes, reducing processing time. |

| Deep Vacuum Capability | Enables precise control of environment conditions. |

| Energy Efficiency | Reduces power consumption, decreasing operational costs. |

| Durable Construction | Minimizes maintenance needs and enhances longevity. |

| User-friendly Interface | Facilitates ease of use and reduces training time for operators. |

| Versatile Application Range | Capable of supporting various industrial processes, enhancing operational flexibility. |

Applications in Various Industries

The Garwin G450 Vacuum Pump finds applications across diverse sectors. In the pharmaceutical industry, it is pivotal in processes such as freeze-drying and solvent recovery. Freeze-drying, or lyophilization, is a method utilized to preserve pharmaceuticals by removing moisture without damaging the product. This process is vital in maintaining the integrity of sensitive compounds. In the food processing industry, the pump is employed for packaging, ensuring products remain fresh and uncontaminated. Vacuum sealing, for instance, is widely embraced to extend the shelf life of food without the use of preservatives. In addition, the chemical industry relies on it for distillation and degassing operations. The ability to achieve a high-quality vacuum is essential in separating chemicals based on boiling points effectively, which is a critical process in chemical manufacturing and preparation.

Moreover, in the electronics sector, the Garwin G450 is used to create controlled atmospheres necessary for manufacturing components like semiconductors. Creating vacuum environments minimizes contaminants during production, which can significantly impact the efficiency and reliability of electronic devices. In robotics and material handling, the pump's capacity to generate vacuum power allows for automated processes such as pick-and-place applications, further improving efficiency in manufacturing settings.

Expert Insights and Recommendations

Industry experts consistently recommend the Garwin G450 due to its adaptability and performance. Its innovative design and quality build make it a top choice for professionals across sectors. Many have noted its robust performance in high-stress environments, where other pumps may fail. Such reliability often leads to prolonged equipment life and higher return on investment for companies using the Garwin G450.

Furthermore, integrating new technologies with the Garwin G450 can enhance its capabilities, making it a future-proof investment for businesses aiming to maintain competitive edges. Advanced sensors for monitoring performance metrics, smart connectivity features for remote operation, and predictive maintenance systems can all be integrated with the G450. As organizations increasingly turn to Industry 4.0 practices, those who invest in enhancing their vacuum systems will benefit from increased efficiency and reduced costs.

Maintenance Best Practices

Routine maintenance practices are crucial for keeping the Garwin G450 functioning optimally. Regular checks and prompt servicing of worn-out parts will ensure the pump operates without issues. It is essential to follow the manufacturer's maintenance guidelines strictly. Routine inspections should include checking oil levels, replacing filters, inspecting hoses for wear, and ensuring seals remain intact. Delaying maintenance can lead to performance degradation, increased energy consumption, and unexpected downtimes.

Another significant aspect of maintenance is training personnel adequately. Operators should receive comprehensive training on the G450’s functionalities, including understanding warning signals and how to respond to common malfunctions. Implementing a proactive maintenance strategy that includes scheduled service intervals and prompt attention to repair needs can significantly extend the lifespan of the pump and ensure ongoing high performance.

FAQs

- What maintenance does the Garwin G450 require?

Regular checks and prompt servicing of worn-out parts will ensure the pump operates without issues. It is essential to follow the manufacturer's maintenance guidelines. Attention to lubrication frequency and maintaining cleanliness around the pump are also paramount.

- Is the Garwin G450 suitable for remote locations?

Yes, the pump's robust construction makes it ideal for use in challenging environments, including remote areas requiring reliable equipment. Many operations can be performed without constant supervision, adding to the G450's attractiveness for remote settings.

- Can the pump be integrated with existing systems?

Absolutely, the Garwin G450's design allows it to be seamlessly integrated with existing industrial systems, enhancing overall process efficiency. The ability to interface with various automation systems makes the G450 versatile and adaptable to a wide range of operational requirements.

- What is the expected lifespan of the Garwin G450?

The expected lifespan can vary depending on the frequency of use and maintenance practices. However, with proper care, many users report performance stability for over a decade. Regular maintenance plays a crucial role in achieving this longevity.

- Does Garwin offer support for troubleshooting issues?

Yes, Garwin provides a dedicated support team for troubleshooting and general inquiries, ensuring that users can quickly resolve any issues that may arise during operation. Access to technical resources online also aids in quick fault diagnosis.

Future Trends and Developments

As technology progresses, the future of vacuum pumps is likely to be shaped by several significant trends. First, the increasing emphasis on energy efficiency and sustainability will push manufacturers like Garwin to innovate further. Future models of the G450 may incorporate advanced energy recovery systems, allowing pumps to utilize energy more efficiently, thereby reducing their carbon footprint. This trend is critically relevant as industries seek to comply with stricter environmental regulations and corporate sustainability goals.

Another trend is the ongoing digital transformation within industries. Vacuum pumps are expected to become more integrated with IoT technologies, enabling real-time monitoring and data analysis. This data can yield insights into performance trends, helping operators anticipate maintenance needs and optimize workflows. Predictive analytics will enable businesses to identify potential failures before they occur, leading to enhanced reliability and efficiency across operations.

Additionally, advancements in materials science may lead to the development of lighter yet more durable pump components, further enhancing the portability of devices and extending service life. Innovations may also include cost-effective ways to address sound and vibration issues that can be particularly important in certain applications.

Conclusion

The Garwin G450 Vacuum Pump exemplifies the pinnacle of industrial pumping technology. With its superior features and broad range of applications, it plays a vital role in various sectors, from pharmaceuticals and food production to electronics and material handling. As industries continue to evolve and adapt to new challenges, the Garwin G450 stands out as a reliable partner, ensuring efficient processes and high-quality outputs. By investing in such advanced equipment, businesses can enhance their operational efficiencies, improve product quality, and remain competitive in an increasingly demanding market. The future of industrial vacuum solutions looks promising as trends toward sustainability, digital integration, and material innovation shape new developments.