Comprehensive Guide to the Garwin G450 Vacuum Pump

Discover the capabilities of the Garwin G450 Vacuum Pump, a versatile tool revered in various industries for its efficiency and reliability. This article delves into its unique features, operational efficiencies, and diverse applications, providing a thorough understanding for professionals seeking optimal vacuum solutions.

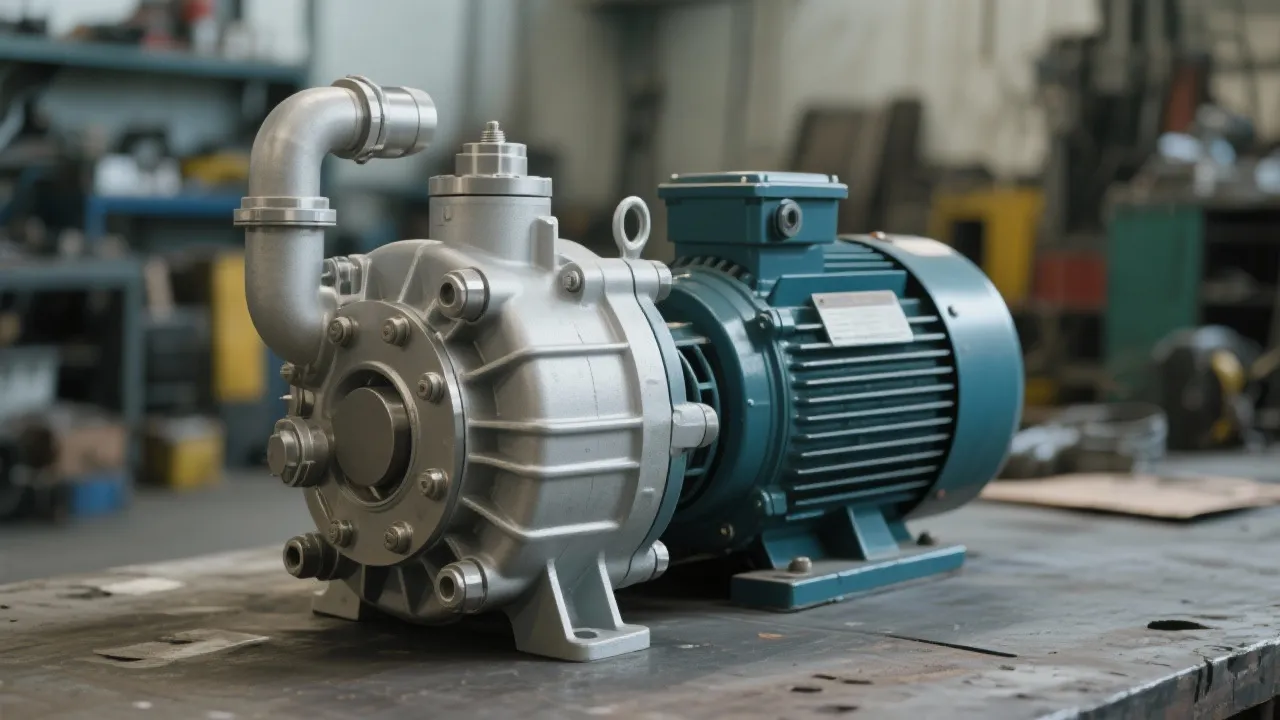

Understanding the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump stands out in the realm of industrial equipment, known for its outstanding performance in maintaining efficient vacuum levels across various operations. Renowned for its durability and advanced technological integration, this vacuum pump is a critical asset in sectors requiring precise and reliable vacuum conditions. With its innovative features and practical designs, the Garwin G450 has evolved to meet the demanding needs of modern industries, redefining the standards for vacuum pump solutions. Understanding these features can help potential users appreciate the pump's impact and significance within their operational frameworks.

Key Features and Benefits

One of the defining attributes of the Garwin G450 Vacuum Pump is its high efficiency, characterized by its ability to deliver consistent performance with minimal energy consumption. The pump’s robust construction ensures longevity, even under demanding operational conditions. Made from high-quality materials resistant to wear and tear, it can function effectively in both continuous and intermittent operation scenarios. Furthermore, its design incorporates advanced noise reduction technologies, making it ideal for use in environments where minimal operational noise is paramount.

Additionally, the G450 model features cutting-edge monitoring systems that integrate data analytics to predict potential failures, allowing for preemptive maintenance that can save time and costs in the long run. This predictive maintenance aspect underscores Garwin's commitment to advancing user experience and operational efficiency. Moreover, the vacuum pump is equipped with thermal overload protection, which prevents overheating and ensures operational safety, further adding to its list of dependable benefits.

Applications Across Industries

The versatility of the Garwin G450 Vacuum Pump allows it to be deployed across a wide range of industries. In the manufacturing sector, it plays a crucial role in processes such as material handling, coating, and drying. For instance, in packaging processes, where vacuum sealing is essential for preserving products, the G450 ensures optimal conditions that prolong shelf life and maintain quality. The precise level of vacuum it offers is invaluable for achieving superior results in products that require a sealed environment.

The pharmaceutical industry relies on the G450 for the precision required in the production of sensitive compounds. Processes such as lyophilization—where moisture is removed from materials under vacuum to preserve them—are critical in this sector, and the G450’s reliability plays a fundamental role in ensuring that these processes are carried out successfully. Similarly, in the electronics sector, the pump is instrumental in ensuring the clean and controlled environments necessary for the production of semiconductors and other delicate components. Given the intricate manufacturing processes in electronics, having a vacuum solution like the G450 can significantly decrease the risk of contamination and defects.

Beyond pharmaceuticals and electronics, the G450 is also utilized in laboratories for applications such as distillation and filtration. The need for stringent vacuum conditions in laboratory settings makes the Garwin G450 a preferred choice among professionals seeking quality and trustworthiness in their equipment. Its applications extend even further into the food and beverage industries, where it helps in processes like vacuum brewing and packaging, ensuring that the end products are both safe and of high quality.

Technological Innovations and Maintenance

Technological advancement in the Garwin G450 is evident in its intelligent control systems, which enhance operational efficiency by automatically adjusting to fluctuations in required vacuum levels. The intelligent software interfaces not only provide real-time data but also allow for remote monitoring and management, giving operators the ability to control the pump from a distance. This adaptability not only optimizes performance but also contributes to prolonged equipment life by minimizing wear and tear. Recent enhancements have made remote troubleshooting easier, reducing downtime and maintenance costs for users.

Regular maintenance of the pump is simplified through its user-friendly design, which allows for quick access to essential components for routine checks and servicing. Garwin has also developed detailed yet easy-to-follow maintenance guides and kits that equip end-users with the tools necessary for basic upkeep. For more complex repairs, authorized service centers offer professional assistance, ensuring that users receive expert care without compromising the performance of their equipment.

In addition, the G450 comes with a comprehensive warranty period that reflects Garwin’s confidence in the product's durability. This warranty not only safeguards the investment made by companies but also exemplifies Garwin's commitment to customer satisfaction. Users are encouraged to keep a meticulous maintenance schedule, as this allows them to maximize the benefits of the pump over its operational lifespan. Strategies for regular maintenance include checking seals for any wear, ensuring that the lubrication is optimal, and observing any unusual noises or vibrations during operation.

Comparison with Similar Models

| Model | Efficiency | Noise Level | Applications |

|---|---|---|---|

| Garwin G450 | High | Low | Manufacturing, Pharmaceuticals, Electronics |

| Competitor A | Moderate | Moderate | General Industrial Use |

| Competitor B | High | High | Heavy-Duty Industries |

When comparing the Garwin G450 to similar models in the market, it is evident that its high efficiency and low noise levels provide it with a competitive edge. Many competitors, while offering high efficiency, compensate with increased noise levels that can disrupt workplace environments. Moreover, the G450's application versatility sets it apart, as it is not limited to heavy-duty industries but is also adaptable for sensitive settings like laboratories and pharmaceutical manufacturing.

Competitor A, for example, may be suitable for general industrial use, but it lacks the advanced features that make the G450 a more compelling choice for industries that prioritize precision and operational integrity. Meanwhile, Competitor B, while offering high efficiency, may not cater well to environments where noise levels are a concern.

The Garwin G450's commitment to innovation and customer satisfaction is reflected in ongoing developments. Continuous feedback from users helps the company adapt its products to ever-evolving industry requirements, ensuring the G450 remains relevant and highly sought-after within the market.

FAQs

- What is the typical lifespan of a Garwin G450 Vacuum Pump? With proper maintenance, the lifespan can extend beyond ten years, offering a robust investment for businesses in need of reliable vacuum solutions.

- Are there any specific installation requirements? Ensure it is placed on a stable surface with adequate space for air intake and exhaust. Additionally, the pump should be installed in an environment that is free from excessive dust and moisture to maintain its efficiency.

- How often should the filters be replaced? Filters should generally be replaced every six months, depending on usage conditions. In high-use environments, monitoring the condition of the filters more frequently is recommended.

- Is technical support available? Garwin provides comprehensive technical support through authorized service centers. Users also have access to detailed manuals and online resources to assist with troubleshooting and maintenance.

- Can the Garwin G450 be used in hazardous environments? While the G450 is built for durability, specific models or modifications may be required for hazardous environments. Always consult with Garwin to determine the best solutions for unique requirements.

- What maintenance practices should be prioritized for optimal performance? Regularly check oil levels, inspect and replace filters, and monitor for any unusual sounds during operation. Keeping the unit clean and free of debris will also contribute to its longevity.

Conclusion

The Garwin G450 Vacuum Pump is a testament to engineering excellence, offering a blend of reliability, efficiency, and advanced technology. Its role in enhancing operational capabilities across various industries is undisputed, making it a top choice for businesses seeking dependable vacuum solutions. The thoughtful design incorporated within the G450 does not merely address current industrial needs but anticipates future demands as well.

As industries continue to innovate, the adaptability and longevity offered by the Garwin G450 equip businesses to navigate a rapidly changing landscape. Future innovations and continuous improvements promise to further strengthen its position as an industry leader, ensuring that it remains at the forefront of vacuum technology. Investing in a Garwin G450 is not just a decision for today, but a strategic choice that prepares operations for the challenges of tomorrow.

Ultimately, the investment in the Garwin G450 Vacuum Pump reflects a commitment to quality, efficiency, and innovation. Companies across various sectors can confidently utilize this pump to enhance productivity while ensuring compliance with industry standards and environmental requirements. As the industrial landscape evolves, the Garwin G450 will undoubtedly adapt and continue to meet the rigorous demands of its users.