Understanding the Garwin G450 Vacuum Pump

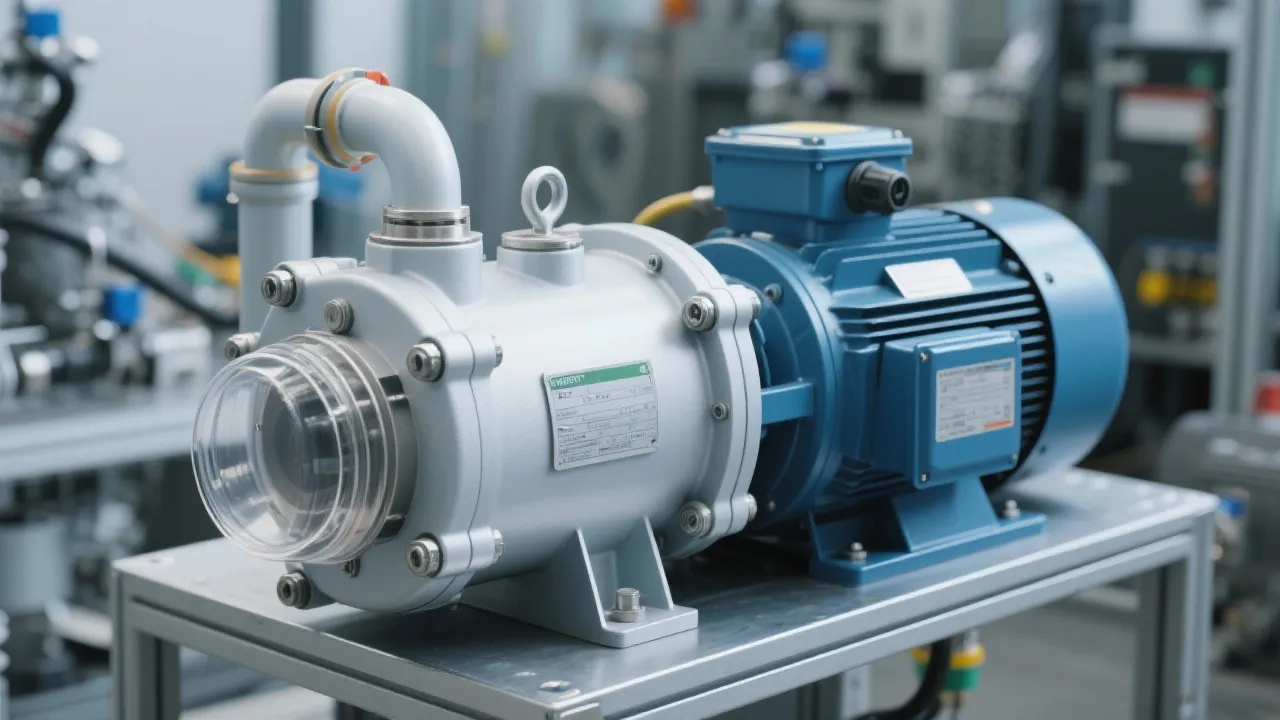

The Garwin G450 Vacuum Pump is a crucial component in various industrial applications, known for its efficiency and reliability. This article delves into the features and benefits of the Garwin G450, drawing on expert insights to provide a detailed analysis of its functionality and performance in the field. Discover how this vacuum pump stands out in technology-driven environments and what makes it a preferred choice for specialists.

Introduction to Vacuum Technology

The world of vacuum technology plays a vital role in numerous industrial processes, from manufacturing to scientific research. Vacuum systems are used to create a controlled environment where certain processes can be performed without the interference of gases and impurities that are usually present in the atmosphere. Among the leading products in this domain is the Garwin G450 Vacuum Pump, a device renowned for its groundbreaking performance and enduring reliability. In this article, we will explore the intricate details of the Garwin G450, providing insights that speak to its groundbreaking role and applications.

Vacuum technology is indeed a complex field that interfaces with a variety of disciplines, including physics, chemistry, and engineering. The applications involve the utilization of vacuum in a myriad of processes, such as thin-film deposition, material processing, vacuum packaging, and even in the field of space technology. This essential technology not only contributes to efficiency but also supports innovation across multiple sectors. Thus, understanding the Garwin G450 becomes imperative to appreciate how vacuum pumps contribute to broader industrial advancements.

Features of the Garwin G450 Vacuum Pump

The Garwin G450 is designed to meet the high demands of various industrial sectors. Its features include:

- Efficiency: The pump boasts a high efficiency rate, reducing operational costs by minimizing energy consumption while maintaining robust performance. It uses advanced technology that optimizes energy use without compromising output, making it an ideal choice for organizations looking to enhance productivity while minimizing costs.

- Durability: Constructed with premium materials, the Garwin G450 ensures good durability and reduced maintenance needs. The rugged design protects vital components from wear and tear, ensuring a longer lifespan and reducing the total cost of ownership over time.

- Compact Design: Despite its powerful functioning, the G450 maintains a compact design, making it easy to integrate into existing systems without requiring additional space. This makes it suitable for various installations, from small workshops to large industrial settings.

- Low Noise: Equipped with noise reduction technology, it operates with minimal sound disturbance, improving workplace conditions. A quieter operation not only makes the work environment more pleasant but also helps meet strict noise regulations in sensitive areas.

- Advanced Control Systems: The Garwin G450 features modern control technology that allows for real-time monitoring and adjustments. Users benefit from intuitive interfaces that provide essential data, enabling smarter operational decisions.

The Industry Impact of the Garwin G450

The introduction of the Garwin G450 Vacuum Pump has brought significant advancements to various industries such as semiconductor manufacturing, pharmaceuticals, and chemical processing. Its consistent performance and energy efficiency have made it a staple in environments where precision and reliability are paramount. The semiconductor industry, in particular, relies on vacuum technology to deposit thin films and to etch patterns on silicon wafers. The G450’s ability to provide a stable, low-pressure environment is crucial for achieving the high-quality results needed in chip production.

In the pharmaceutical sector, maintaining sterile environments is critical for manufacturing processes, from the production of medicines to the packaging of drug products. The Garwin G450's reliability ensures that these processes meet strict regulatory standards while minimizing contamination risks. Furthermore, its efficiency plays a role in lowering the costs associated with pharmaceutical production, which is increasingly vital in a market where margins are continuously squeezed.

Additionally, the chemical processing industry utilizes vacuum technology for processes such as distillation, drying, and concentration, where the removal of unwanted gases or vapors is essential. The G450 provides the necessary pressure conditions to optimize these processes, contributing to improved yield and product quality. By delivering dependable performance, the Garwin G450 strengthens the operational capabilities of these critical industries, further showcasing the pump's diverse applicability and importance.

Technical Specifications

| Specification | Detail |

|---|---|

| Pumping Speed | 450 m³/h |

| Ultimate Pressure | < 0.03 mbar |

| Motor Power | 5.5 kW |

| Weight | 100 kg |

| Noise Level | 56 dB |

| Air Inlet Diameter | 50 mm |

| Power Supply | 380V/50Hz |

| Cooling Method | Water-cooled |

Expert Insights on the Garwin G450

Industry experts commend the Garwin G450 for its adaptability and consistent performance. According to a leading vacuum technology analyst, "The G450 excels in environments that demand precision, offering unmatched reliability and efficiency." This perception is echoed across various applications where downtime and inaccuracies can lead to significant financial losses. Experts also note that the G450's ability to maintain precise vacuum levels allows for more consistent outputs in manufacturing processes, reducing product variation and improving overall quality.

Furthermore, the flexibility of the G450's design facilitates customization options for various industrial setups. Companies can tailor the pump's operations to meet specific requirements, ensuring a fit-for-purpose solution that aligns with their operational goals. As industries evolve and demand more efficiency and less environmental impact, experts predict that the versatility of models like the Garwin G450 will remain instrumental in driving ongoing advancements in vacuum technology.

Environmental Considerations

With increasing emphasis on sustainability, the Garwin G450 is engineered to comply with environmental regulations. It incorporates eco-friendly components that reduce its carbon footprint, aligning with global efforts to prioritize greener industrial practices. The integration of energy-efficient motors and materials not only reduces energy consumption but also ensures that the manufacturing process adheres to stringent environmental guidelines.

Moreover, the design of the pump minimizes the release of harmful substances into the atmosphere, making it a safer choice in industries that are sensitive to environmental impact. The Garwin G450's commitment to sustainability is also reflected in its ability to be easily serviced and maintained, ensuring that equipment remains in optimal condition for longer periods. This longevity reduces the need for replacements, further supporting eco-friendly initiatives.

Companies that prioritize sustainability within their operations are more competitive in today’s market, where consumers increasingly favor environmentally responsible brands. The Garwin G450, with its eco-conscious design and operation, not only enhances a company’s productivity but also reinforces its commitment to sustainability.

FAQs

- What industries benefit very much from the Garwin G450 Vacuum Pump?

The G450 is invaluable in sectors such as semiconductor manufacturing, pharmaceuticals, and chemical processing due to its precision and reliability. In addition, it finds utility in the food industry, vacuum sealing, and even in research laboratories where maintaining a specific atmospheric condition is critical.

- How does the Garwin G450 contribute to energy savings?

Its high-efficiency motor reduces power consumption, thereby lowering operational costs and promoting energy conservation. In fact, energy audits have shown that using the G450 can lead to noticeable reductions in annual energy costs compared to older, less efficient pump models.

- Is the Garwin G450 suitable for all climates?

Yes, the Garwin G450 is designed to perform optimally across a range of environmental conditions, ensuring consistent output worldwide. It can adapt to varying temperatures and humidity levels, enabling it to function effectively in both temperate and extreme climates.

- What maintenance does the Garwin G450 require?

Regular maintenance for the G450 includes checking and replacing filters, monitoring for oil levels, and ensuring the cooling system is functional. Adopting a routine maintenance schedule not only prolongs the pump's lifespan but also ensures it operates with peak efficiency.

- Can the Garwin G450 be integrated with existing vacuum systems?

Yes, the compact design and flexible specifications of the G450 facilitate easy integration into existing vacuum setups. Its compatibility with various systems ensures that upgrading to the G450 can enhance overall performance without the need for a complete overhaul.

- What safety features does the Garwin G450 include?

The G450 comes equipped with several safety features, including automatic shutdown in case of overheating and pressure regulation systems to prevent backflow. These safety mechanisms protect both the equipment and operators, enhancing the safety profile of industrial operations.

Applications of the Garwin G450 Vacuum Pump

The versatility of the Garwin G450 extends to numerous applications across various sectors. Some notable applications include:

- Semiconductor Manufacturing: The G450 is used in processes such as vacuum deposition, where thin films are applied to semiconductor wafers. This application is critical for producing modern electronics, which rely on precise control of the deposition environment.

- Pharmaceutical Production: In pharmaceuticals, the pump supports sterile manufacturing processes, ensuring that products are free from contamination. It is particularly used during the lyophilization (freeze-drying) process, where removing moisture is essential for product stability.

- Chemical Processing: The G450 is indispensable in chemical manufacturing, where vacuum is required for distillation and extraction processes. Its reliability ensures high purity and yield of chemical products.

- Food Industry: The pump is employed in vacuum packaging applications that extend the shelf life of food products by preventing oxidation and microbial growth.

- Research and Development: Many laboratories utilize vacuum pumps for a variety of experimental setups, such as vacuum chambers and cryovacuum systems, where controlled environments are critical for accurate scientific results.

Choosing the Right Vacuum Pump

Selecting the appropriate vacuum pump for specific applications involves several considerations. Factors such as required pumping speed, ultimate pressure, material compatibility, and environmental conditions play crucial roles in making the right choice. When evaluating the Garwin G450, potential users must assess how its specifications align with their operational needs.

Additionally, considerations related to maintenance, energy efficiency, and integration capabilities should not be overlooked. Understanding the specific requirements of the application will help ensure that the G450 delivers optimal performance. Engaging with providers for tailored advice can aid in making an informed decision based on industry needs and future growth projections.

Furthermore, prospective buyers may wish to consider feedback from current users regarding performance, durability, and support services. Testimonials and case studies can provide valuable insights into how the G450 performs in real-world scenarios. This corresponds with an informed approach to acquiring vacuum technology that meets both current needs and future growth requirements.

Future Trends in Vacuum Technology

The landscape of vacuum technology continues to evolve, driven by advancements in material sciences, automation, and digitalization. Smart technologies are increasingly being integrated into vacuum pumps, allowing for sophisticated monitoring and control of performance metrics in real-time. This trend is expected to revolutionize maintenance strategies, enabling predictive maintenance based on actual usage patterns rather than scheduled interventions.

As industries strive to minimize their environmental impact, the focus on energy efficiencies will only intensify. Future developments in vacuum technology will likely prioritize eco-friendly materials and processes that reduce waste and optimize energy use even further. Innovations such as hybrid systems that combine different pumping technologies may also emerge, giving users even more options tailored to specific applications.

The Garwin G450, with its forward-thinking design, stands poised to meet these evolving demands in vacuum technology, supporting industries through adaptability and efficiency. By embracing these changes, manufacturers and research institutions can pave the way for a more sustainable and technologically advanced future.

Conclusion

The Garwin G450 Vacuum Pump represents a significant achievement in vacuum technology, combining efficiency, durability, and adaptability in its design. Its applications across critical sectors such as semiconductor manufacturing, pharmaceuticals, and chemical processing showcase its vital role in modern industrial operations. The G450 not only meets the rigorous demands of these industries but also aligns with contemporary values of sustainability and economic efficiency.

As industries continue to evolve and adapt to new challenges, the Garwin G450 will undoubtedly remain a cornerstone of reliable vacuum solutions. Technology will advance, and through it, vacuum technology will play a pivotal role in shaping future industrial processes. By leveraging innovative products like the G450, companies can improve operational efficiencies, reduce environmental impacts, and drive further advancements in production methodologies.

Overall, understanding and adopting technologies such as the Garwin G450 is essential for businesses aiming to stay competitive and sustainable in the ever-changing landscape of industry. Investments in quality vacuum technology are investments in future growth and resilience.