Understanding the Garwin G450 Vacuum Pump

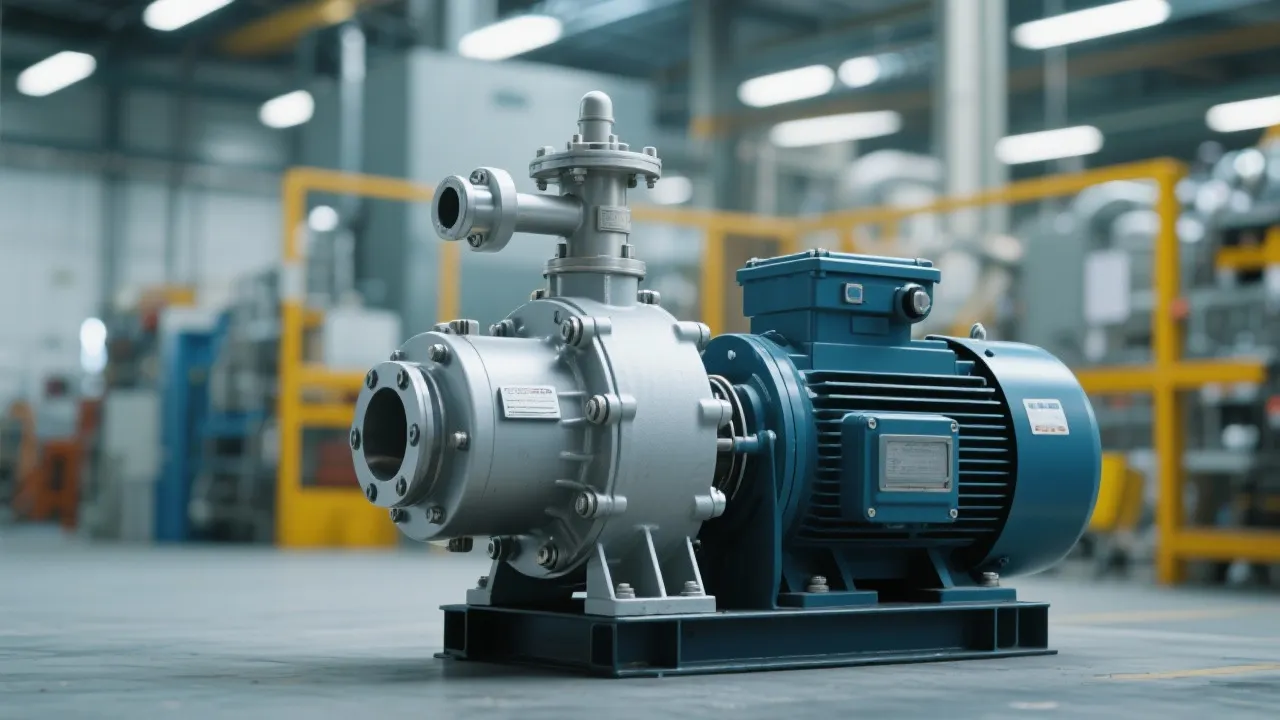

This guide explores the Garwin G450 Vacuum Pump, a device renowned for its efficiency and reliability in industrial applications. Vacuum pumps are essential in various industries, helping to create a vacuum space by removing gas molecules. The Garwin G450 model stands out due to its advanced technology, durability, and versatility, making it a preferred choice for many businesses.

Introduction to the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is a leading piece of machinery cherished for its potent capability to create vacuum conditions by efficiently removing gas molecules from a sealed environment. As an indispensable tool in numerous industrial sectors, this pump boasts advancements in technology, reliability, and user-centric design, which together elevate it above many of its competitors. Designed for performance and enhanced with the latest technology innovations, the Garwin G450 is a cornerstone in modern vacuum solutions.

The Importance of Vacuum Pumps in Industry

Vacuum pumps like the Garwin G450 play a pivotal role in various industries—from automotive to pharmaceuticals—by maintaining optimal operating conditions. These devices work by decreasing the pressure within a chamber, facilitating processes that improve product quality and operational efficiency. The vacuum created is essential for applications like drying, degassing, and air conditioning production. The significance of effective vacuum generation cannot be overstated; it is crucial for minimizing contaminants during pharmaceutical manufacturing and ensuring the longevity of products in the food industry.

In the automotive sector, for example, vacuum pumps are integral during component assembly processes, where precise liquid application and air removal are necessary to enhance adhesion quality and restore durability. In laboratories, the ability to maintain low-pressure environments is vital for experiments and the preservation of sensitive samples. As industries continue to evolve, the need for reliable vacuum solutions, such as those provided by the Garwin G450, becomes increasingly important for maintaining competitiveness, compliance with regulatory standards, and ensuring the highest quality in products and services.

Garwin G450 Features and Specifications

At the heart of the Garwin G450 Vacuum Pump lies its advanced engineering, which ensures both performance and efficiency. Key features include a robust motor, precision components, and a user-friendly interface designed to facilitate straightforward operation and monitoring. Built with high-quality materials, the G450 is designed to withstand high operational demands, reflecting a dedication to durability and good viability.

| Feature | Specification |

|---|---|

| Maximum Flow Rate | 250 cubic meters per hour |

| Ultimate Vacuum | 0.5 mbar absolute |

| Power Consumption | 5.5 kW |

| Noise Level | 72 dB at 1 meter |

| Weight | 120 kg |

Each of these specifications underscores the pump's capability to perform under rigorous conditions while maintaining operational efficiency. For instance, its impressive maximum flow rate of 250 cubic meters per hour makes it suitable for larger scale applications, while the ultimate vacuum capability of 0.5 mbar ensures that it can handle tasks that require extreme low-pressure environments.

How the Garwin G450 Compares to Other Models

When compared to other vacuum pumps in the market, the Garwin G450 offers superior energy efficiency and lower noise levels, making it an attractive choice for a wide range of applications. Its robust construction enables it to handle more rigorous applications without compromising on performance. When evaluating similar models, factors such as maintenance costs, ease of operation, and compatibility should also be considered.

For example, models from competing brands may present lower purchase prices but can entail higher energy costs and expensive repairs due to less durable construction. The G450's reputation for reliability often leads to reduced downtime in production lines, directly contributing to improved overall productivity and cost savings in the long run. Additionally, the Garwin G450 often features a modular design, allowing for easy upgrades in technology as new innovations emerge without needing to replace the entire unit.

Installation and Maintenance

- Installation: Setting up the Garwin G450 involves securing it in a stable environment, connecting the necessary inlet and outlet pipes, and ensuring an adequate power supply to match its specifications. It is critical to ensure that all fittings are secure to avoid any leaks, which could compromise performance. Proper alignment and vibration dampening are also essential during installation to extend the life of the pump.

- Maintenance: Regular maintenance involves checking for wear and tear, ensuring seals and gaskets are intact, and lubricating moving components to prevent unnecessary friction. Routine inspections will prolong the lifespan of the pump. Additionally, users are encouraged to keep the pump clean and ensure that cooling systems are functioning correctly. Maintenance schedules should be established based on operational hours and specific environmental conditions to anticipate when parts may need replacing or servicing.

The importance of adhering to maintenance schedules can be emphasized further; neglecting regular checks can result in reduced performance, increased energy consumption, and potentially costly repairs. Moreover, users should keep detailed logs of maintenance activities, as this not only helps track the pump's performance over time but can also improve the reliability of warranty claims when necessary.

Application of the Garwin G450 Vacuum Pump

The versatility of the Garwin G450 makes it suitable for a range of applications across various sectors. In the pharmaceutical industry, for instance, this pump is commonly used during the formulation and packaging processes, helping maintain sterile environments and ensuring that medications remain uncontaminated. Moreover, its ability to achieve low vacuum levels is critical when dealing with products sensitive to oxidation, where controlled atmospheric conditions are necessary to safeguard product integrity.

In the food processing industry, vacuum technology plays a central role in packaging, allowing for extended shelf lives by limiting oxygen exposure. The Garwin G450's ability to create a reliable vacuum assists food manufacturers in efficiently packing goods without compromising their freshness. Additionally, this pump is pivotal in processes like freeze-drying and degassing, where removing air from within products is vital for preserving flavor and texture.

In laboratories, the G450 is employed in various tasks, from scientific experiments to equipment maintenance. Its precision and reliability allow researchers to create controlled environments for critical experiments, especially in areas like materials science and chemical research. Laboratories across disciplines have recognized the Garwin G450 for its contribution to enhancing the reproducibility and accuracy of results.

Energy Efficiency of the Garwin G450

As industries increasingly focus on sustainability, the energy efficiency of equipment like the Garwin G450 has become a significant selling point. This pump is designed not only for performance but also to minimize energy consumption while maximizing output. By employing advanced technology, such as variable speed drives, the G450 can operate at optimal efficiency levels tailored to the specific demands of the application.

Lower energy consumption does not only equate to cost savings for the end-user but also contributes to environmental sustainability by reducing the overall carbon footprint of industrial processes. Industries utilizing the Garwin G450 can promote their commitment to eco-friendly practices, which can enhance their brand image and competitiveness in the market.

Performance Monitoring and Troubleshooting

The Garwin G450's user-centric design includes features for performance monitoring, allowing operators to track the condition and efficiency of the pump in real-time. This feature enables early detection of issues before they lead to significant downtime or costly repairs. Indicators such as temperature, pressure readings, and flow rates can offer insights into the pump's operational health. By keeping an eye on these metrics, operators can make informed decisions on when maintenance is required.

In the event of performance degradation, troubleshooting the Garwin G450 can often be straightforward. Common issues may include abnormal noise levels, fluctuations in vacuum pressure, or changes in efficiency. Each of these symptoms can typically be traced back to easily identifiable causes, such as blockages in the inlet or outlet, worn seals needing replacement, or inadequate power supply. Essential troubleshooting information is detailed in the user manual, providing operators with guidance on how to systematically diagnose and resolve issues, thereby minimizing disruptions to operations.

Training and Support for Users

To maximize the effectiveness of the Garwin G450 Vacuum Pump, proper training and support for users are crucial. Many manufacturers, including Garwin, provide comprehensive user manuals and additional training resources to educate users about the operation and maintenance of their pumps. Understanding how to operate the pump efficiently and safely can enhance not only the pump's performance but also the safety of the operating environment.

Support services, such as customer helplines and on-site training sessions, can also assist operators in familiarizing themselves with advanced functionalities or troubleshooting procedures. Investing time in training ensures that personnel are confident when handling equipment, reducing the likelihood of mishaps and ensuring regulatory compliance within sensitive environments.

FAQs

- Q: What industries benefit most from the Garwin G450?

- A: Industries such as pharmaceuticals, automotive, and food processing significantly benefit due to the pump’s reliable and efficient performance. Additionally, sectors like electronics manufacturing and research labs utilize vacuum pumps for precise vacuum control and product integrity.

- Q: What is the expected lifespan of the Garwin G450?

- A: With regular maintenance, the pump can last over a decade without major issues. Users are encouraged to adhere to maintenance schedules to maximize lifespan and operational efficiency.

- Q: Can the Garwin G450 be used in cleanroom environments?

- A: Yes, its design and construction make it suitable for cleanroom applications where sanitary conditions are necessary. The choice of materials and sealing technology used in the Garwin G450 ensures it meets the stringent requirements of clean room certifications.

- Q: Is the Garwin G450 energy efficient?

- A: Yes, the Garwin G450 is designed for energy efficiency, employing advanced technology to minimize energy consumption while maximizing output, making it not only cost-effective but also environmentally friendly.

- Q: How can I ensure that my Garwin G450 operates at peak performance?

- A: Regular maintenance, routine checks for unusual signs of wear, and following the manufacturer’s guidelines for operation and troubleshooting will help ensure optimal performance. Additionally, monitoring key performance indicators can alert users to the need for maintenance before issues become more severe.

Conclusion

In conclusion, the Garwin G450 Vacuum Pump stands out as a premier choice for businesses seeking efficiency combined with durability. Its advanced features and robust design allow it to meet various industrial needs effectively. By choosing the Garwin G450, industries can enhance their operational capabilities and enjoy a reliable service experience. The ongoing commitment to innovation in both design and functionality positions the Garwin G450 not only as an essential tool for today’s industrial applications but also as a forward-thinking solution that aligns with the evolving demands of the marketplace.

As industries look towards future advancements and improvements, the versatility and reliability of the Garwin G450 ensure that it will remain a vital part of industrial processes for years to come. With continued investment in research and development and partnerships with key industry stakeholders, the Garwin G450 stands ready to evolve in line with technological advancements and the ever-changing landscape of industry demands.

This long-term perspective is not only beneficial for current users but also fortifies the Garwin brand reputation, making the G450 a trusted choice for new customers seeking robust and efficient vacuum solutions.