Comprehensive Guide to Garwin G450 Vacuum Pump

This article provides an in-depth analysis of the Garwin G450 Vacuum Pump, an essential tool in various industries requiring precision pressure control. Known for its efficiency and reliability, the G450 model is favored in sectors such as manufacturing, pharmaceuticals, and laboratories. It illustrates the pump's technological features, industry applications, and common concerns, offering valuable insights for businesses considering investment.

Understanding the Garwin G450 Vacuum Pump

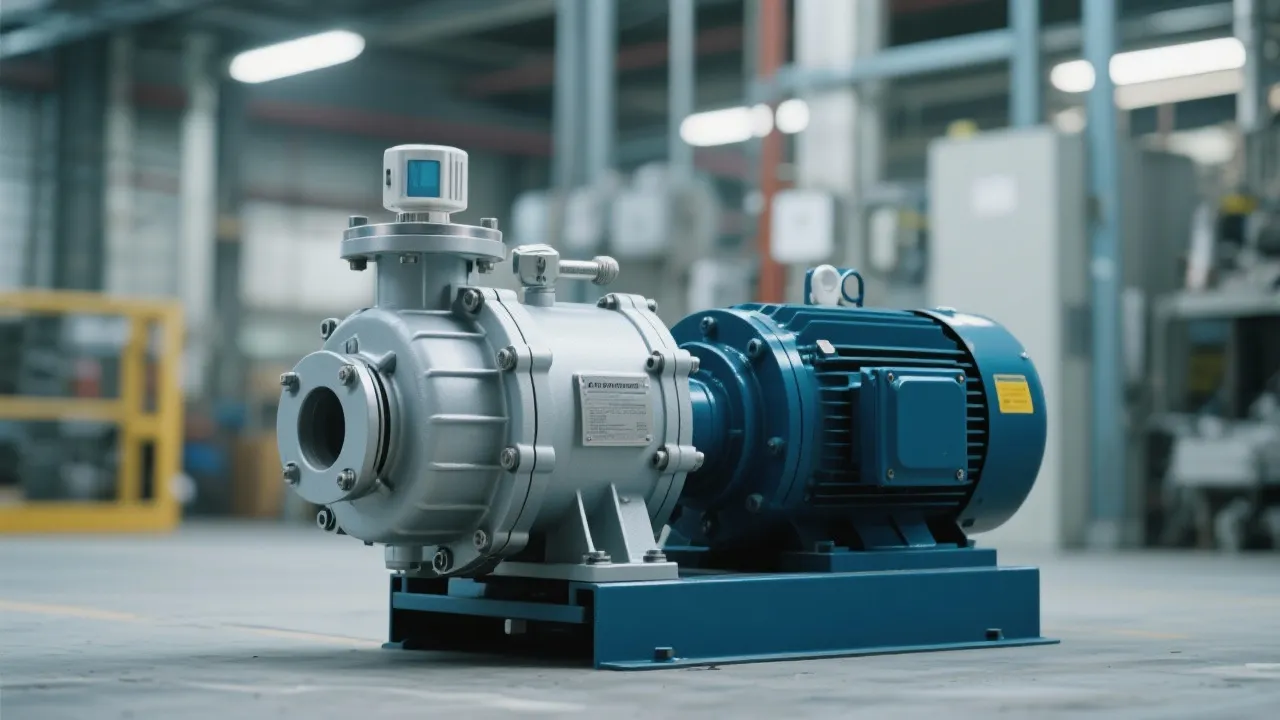

The Garwin G450 Vacuum Pump is a powerful piece of technology used across multiple industries where precise pressure management is crucial. This vacuum pump is renowned for its compact design, durability, and efficiency, making it an excellent addition to manufacturing units, labs, and pharmaceutical environments. In today’s competitive business landscape, such equipment is indispensable for maintaining quality control and ensuring operational efficacy. The application of vacuum pumps like the Garwin G450 can lead to optimized processes, reduced costs, and improved safety across various operations.

Developed with advanced engineering and stringent quality control standards, the G450 exemplifies the latest innovations in vacuum pump technology. Its ability to maintain a stable vacuum under fluctuating operational conditions speaks volumes about its reliability. In environments where every second counts and process consistency is non-negotiable, investing in high-quality machinery like the Garwin G450 becomes a strategic business decision. Not only does it enhance the overall productivity of a business, but it also significantly impacts the quality of the final product, making it essential to consider for companies striving for excellence.

Core Features and Benefits

What sets the Garwin G450 apart is its ability to deliver consistent performance under varied conditions. The pump is designed to handle demanding environments, providing reliable vacuum levels with minimal noise and vibration. Its energy-efficient operation helps reduce operational costs, making it a preferred choice amongst cost-conscious businesses. Furthermore, the G450’s ease of maintenance means less downtime, enhancing overall productivity. One of the key advantages is its swift startup time, allowing businesses to ramp up operations quickly and efficiently.

In addition, the machine’s modular design permits straightforward customization and upgrades, which ensures longevity and future-proofs your investment. Maintenance personnel can easily swap out components as technology evolves or as operational needs change. The Garwin G450’s compatibility with various applications—from chemical processing to food packaging—demonstrates its versatility. Its robust build and smart control system also contribute to its widespread industry application, ensuring it performs well even in harsh conditions or rigorous usage scenarios.

The digital control interface of the Garwin G450 also allows operators to monitor performance in real-time, helping to identify potential issues before they escalate into costly downtime or repairs. This proactive management approach is essential for businesses that prioritize reliability and efficiency. Coupled with the thorough user manuals and customer support provided by Garwin, integrating the G450 into existing systems becomes a streamlined process.

Applications of the Garwin G450 Vacuum Pump

Industries utilizing the Garwin G450 Vacuum Pump find value in its adaptability to different environments. In the manufacturing sector, it aids in tasks such as material handling and degassing. The G450 plays a vital role in the production of high-quality goods, ensuring that materials and components are free of air pockets and impurities that could compromise product integrity. Additionally, in assembly lines, it is crucial for tasks such as vacuum sealing, which enhances product longevity and safety.

In laboratories, the pump is ideal for processes like filtration and drying, where precise pressure control is crucial. Research settings benefit from its reliability, as accurate results hinge on controlled environments. From academic institutions to industrial laboratories, the Garwin G450 supports experiments and processes that demand high precision. Its application extends to sensitive processes, such as in biotechnology and analytics, where contamination must be avoided at all costs.

In the pharmaceutical industry, businesses benefit from using the G450 in freeze-drying processes and ensuring the sterility of operations. The capability to achieve and maintain vacuum levels allows for the preservation of sensitive compounds and active ingredients, thereby extending shelf life and effectiveness. Beyond pharmaceuticals, it is also widely used in the food processing industry for vacuum packaging and preservation techniques that help to maintain freshness while extending the shelf life of products. This extends to areas such as meat processing, ready-to-eat meals, and packaged produce where vacuum technology helps prevent spoilage and waste.

Considerations for Investment

Before investing in the Garwin G450, consider the specific requirements of your operation. Assess the expected workload and environmental conditions, ensuring that the pump aligns with your business goals. Understanding factors such as the required vacuum level, flow rate, and the materials being processed will help in selecting the right vacuum pump. Consult with suppliers for detailed specifications and compatibility with existing systems, as this insight can provide clarity in making informed decisions.

In addition to technical specifications, financial feasibility is another critical consideration. Analyze not only the upfront costs but also ongoing operational expenses such as maintenance, energy usage, and component replacement. Evaluating the return on investment will detail how the G450 can save money over time through increased efficiency and reduced downtime. You should also consider any training required for staff to operate the equipment effectively.

Additionally, it is beneficial to consult with other industry professionals who have experience with the Garwin G450 or similar vacuum pump technologies. Their insights can provide realistic expectations regarding performance and reliability. Trade shows and industry conferences often feature live demonstrations, allowing prospective buyers to see the pump in action and ask direct questions from manufacturers. Furthermore, consider the warranty and service options available, as this can provide peace of mind in case of unexpected challenges.

| Feature | Benefit |

|---|---|

| Energy Efficiency | Reduces operational costs significantly, contributing to overall profit margins. |

| Compact Design | Saves space and is easy to integrate into existing layouts, allowing for better use of available floor space. |

| Low Maintenance | Enhances uptime and longevity with minimal repairs, which translates into lower lifetime costs. |

| Customizable | Adaptability to various industrial processes enhances operational flexibility. |

| Advanced Control Interface | Allows real-time monitoring and management of pump performance, minimizing risks of failure and optimizing operations. |

| Versatile Applications | Applicable in multiple sectors including manufacturing, pharmaceuticals, food processing, and laboratories. |

FAQs

- What is the lifespan of the Garwin G450 Vacuum Pump?

- How often should the Garwin G450 be serviced?

- Is the Garwin G450 suitable for cleanroom applications?

- Can the G450 handle corrosive materials?

- What is the maximum vacuum level achievable by the Garwin G450?

- Is training available for operators to use the Garwin G450?

The G450 is built for durability, with proper maintenance it can operate efficiently for several years. Typically, users can expect a lifespan of up to 10 years depending on usage patterns and adherence to maintenance schedules.

Routine maintenance is recommended every 6-12 months, depending on the intensity of use and the environmental conditions. Regular checks for wear and tear, as well as replacing consumable parts, can greatly extend the operational life of the pump.

Yes, its low-contaminant design makes it suitable for cleanroom and laboratory settings. This is crucial in environments where even minor contamination can compromise research outcomes or product quality.

It can handle a range of materials, but for highly corrosive substances, specialized components should be used. It's important to consult with the manufacturer regarding specific chemical compatibilities to prevent any premature degradation of the pump.

The Garwin G450 can achieve impressive vacuum levels, typically reaching down to 0.1 mbar, which is suitable for most industrial applications. For detailed specifications, refer to the manufacturer’s guidelines.

Yes, Garwin often provides training resources for operators to ensure they are familiar with the operation and maintenance of the G450, which minimizes the risk of errors and maximizes safety in the workplace.

Conclusion

The Garwin G450 Vacuum Pump is a cutting-edge piece of machinery that stands out in today’s demanding industrial landscape. Its efficiency, reliability, and adaptability make it a valuable asset for any business looking to improve operation efficiency. Whether in manufacturing, laboratories, or pharmaceutical environments, the G450 offers unmatched performance and a secure return on investment.

Investing in the Garwin G450 means equipping your operations with a tool that not only meets the current demands but also adapts to future needs. Its combination of energy efficiency, low maintenance, and broad applicability ensures that it remains relevant as industry standards evolve. Moreover, the widespread trust and positive reviews from existing users attest to its effectiveness and performance improvement across various settings.

In conclusion, as industries continue to innovate and raise benchmarks for quality and productivity, the importance of sophisticated equipment like the Garwin G450 Vacuum Pump cannot be overstated. It's a testament to the advancements in engineering and technology, allowing businesses to thrive in a competitive environment while emphasizing sustainability and efficiency. With proper consideration and investment, the Garwin G450 can significantly enhance process effectiveness, ultimately leading to higher customer satisfaction and business success.