Understanding the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is renowned for its efficiency in removing air and gases, making it indispensable in various industrial applications. This article delves into its operational advantages, providing a comprehensive analysis of its key features, benefits, and considerations for potential users, along with answering frequently asked questions.

Introduction to Vacuum Technology

In industries ranging from electronics to pharmaceuticals, vacuum pumps like the Garwin G450 play a crucial role in maintaining controlled atmospheric conditions. The ability to effectively remove air and other gases is essential for numerous production and research applications, ensuring both precision and safety in operations. Vacuum technology not only aids in maintaining the integrity of sensitive processes but also promotes enhanced efficiency, leading to significant advances in productivity across many sectors.

The Importance of Vacuum Technology

Vacuum technology is vital for various applications that require a controlled and contamination-free environment. In the electronics industry, for example, creating a vacuum is essential to prevent the presence of air and moisture that can damage components during production. Similarly, in the pharmaceutical sector, vacuum technology ensures products are manufactured in sterile conditions, minimizing contamination risks. The applications of vacuum technology extend beyond manufacturing, impacting fields such as research, food processing, and even telecommunications. Each application benefits from the ability to achieve precise atmospheric conditions, which is increasingly important in a world that demands higher standards of quality and safety.

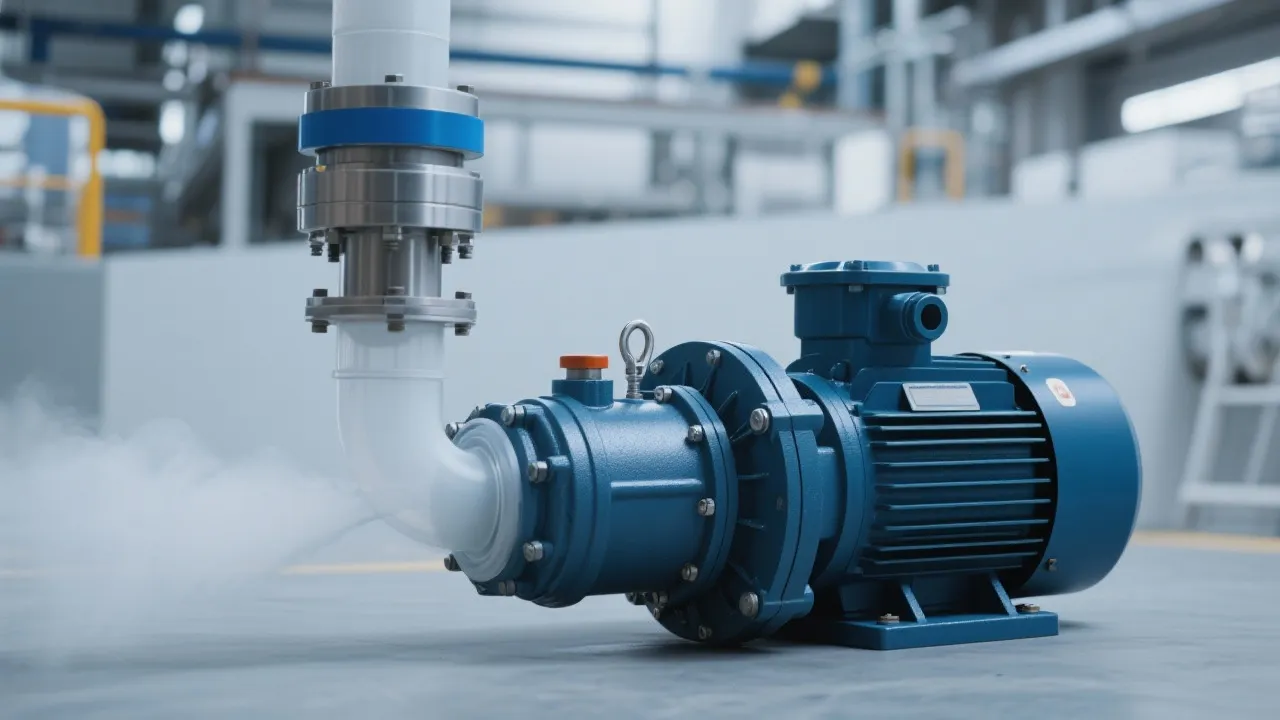

Overview of the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump stands out due to its advanced engineering and robust construction. This device is particularly known for its high efficiency and reliability, making it an excellent choice for businesses requiring dependable vacuum technology. Its design incorporates cutting-edge components that optimize air and gas displacement, ensuring smooth and efficient operation. The G450 is designed to cater to a wide range of applications, providing solutions tailored to both high-performance and standard vacuum requirements.

Key Features of the Garwin G450

- High Performance: Capable of reaching significant vacuum levels, the G450 ensures operations that demand specific atmospheric conditions are met. The precision with which it operates facilitates processes where even slight variations in pressure can lead to flaws in the output.

- Energy Efficiency: Designed with energy-saving features, the G450 minimizes operational costs without compromising performance. By integrating smart technology that adjusts to the operational load, the pump reduces unnecessary energy consumption, making it an environmentally friendly choice.

- Durability: Constructed with high-quality materials, it withstands rigorous use, ensuring longevity and reduced maintenance needs. The robust design means that the pump can handle fluctuations in workload and extreme conditions, which is a common requirement in various industrial environments.

- Noise Reduction: Equipped with noise-reducing technology, it maintains a low operational noise level, enhancing workplace comfort. The ability to operate quietly is particularly beneficial in environments where noise pollution could distract or disrupt workflow.

Operational Benefits

The Garwin G450 is trusted for its operational efficiency and reliability. Industries benefit from its quick startup, minimal downtime, and ease of maintenance. These attributes result in increased productivity and reduced operational costs, a significant advantage for businesses aiming to optimize their processes. With an emphasis on user-friendly operations, the G450 is designed for easy installation and integration into existing systems. The intuitive controls provide operators with the capability to easily monitor performance metrics and make adjustments as needed, leading to smoother operations and enhanced output quality.

Applications of the Garwin G450 Vacuum Pump

The versatility of the Garwin G450 ensures it has applications across various industries. In the electronics sector, it plays a pivotal role in producing semiconductors and microelectronics, where vacuum conditions prevent the introduction of contaminants during delicate production processes. In pharmaceuticals, the G450 helps in drying and packaging drugs in environments that have strict contamination control measures. Moreover, in the research domain, this pump assists in experiments that require vacuum environments, including material science and chemical studies, facilitating innovation through enhanced experimental conditions.

Comparison Table: Garwin G450 and Competitors

| Feature | Garwin G450 | Competitor A | Competitor B |

|---|---|---|---|

| Vacuum Level | High | Moderate | High |

| Energy Consumption | Low | Moderate | High |

| Durability | High | Moderate | High |

| Noise Level | Low | Moderate | High |

| Maintenance Needs | Low | High | Moderate |

Frequently Asked Questions

- What maintenance does the G450 require?

The Garwin G450 requires regular checks and occasional replacement of parts to maintain its efficiency. This includes seals, filters, and oil changes where applicable. Adhering to a routine maintenance schedule ensures that the pump operates at peak efficiency and minimizes the risk of unexpected failures. - How does it compare cost-wise to other models?

While the initial investment may be higher than some models, the Garwin G450 offers superior value due to its efficiency and lower operational costs. The long-term savings achieved through energy efficiency and reduced downtime often outweigh any upfront price differences. - Is it suitable for my industry?

Given its high performance and diverse applications, the G450 is suitable for industries such as electronics manufacturing, chemical processing, and scientific research. The versatility of this pump allows businesses to use it in a range of demanding conditions, adapting to specific requirements across multiple sectors.

Customer Testimonials

Real-world feedback from users highlights the strengths of the Garwin G450. Customers across various industries commend its reliability and performance, with many noting significant improvements in production efficiency since adopting this pump. For example, a leading semiconductor manufacturer reported a decrease in defect rates attributed to the consistent vacuum levels provided by the G450, showcasing its impact on product quality. Similarly, a pharmaceutical company emphasized the importance of maintaining sterile conditions, which the G450 has successfully facilitated, reassuring them of the pump's pivotal role in their production line.

Conclusion

The Garwin G450 Vacuum Pump is a significant player in the field of vacuum technology, offering excellent performance and reliability. While choosing equipment for industrial applications, it's vital to consider not only the immediate costs but also the long-term benefits in efficiency and reliability. The G450 delivers on these crucial factors, making it a smart choice for various industry needs. Investing in reliable equipment like the Garwin G450 ultimately translates into smoother operations, higher product quality, and significant cost savings over time. As industry standards continue to evolve, the dependability of the G450 will likely keep it at the forefront of vacuum technology, meeting and exceeding the expectations of businesses across the board.