Understanding the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is a sophisticated and dependable piece of equipment utilized across a variety of industries for exhausting, evacuating, and transferring gases within closed systems. As a critical tool in sectors like pharmaceuticals, automotive, and chemical processing, its efficiency and reliability make it essential. Learn more about its features, advantages, and practical applications in this comprehensive overview.

Introduction to Vacuum Pumps

Vacuum pumps are essential components in various industrial processes, offering the capability to exhaust, evacuate, or transfer gases. These devices play a pivotal role in creating a controlled environment necessary for many operations across different sectors. Their functionality is vital in processes where the presence of air or other gases could lead to contamination or inefficiency. The Garwin G450 Vacuum Pump stands out due to its efficiency and reliability, making it a preferred choice in industries that require precise vacuum conditions. This introduction delves into the significance of vacuum pumps more broadly, setting the stage for a closer examination of the Garwin G450 model.

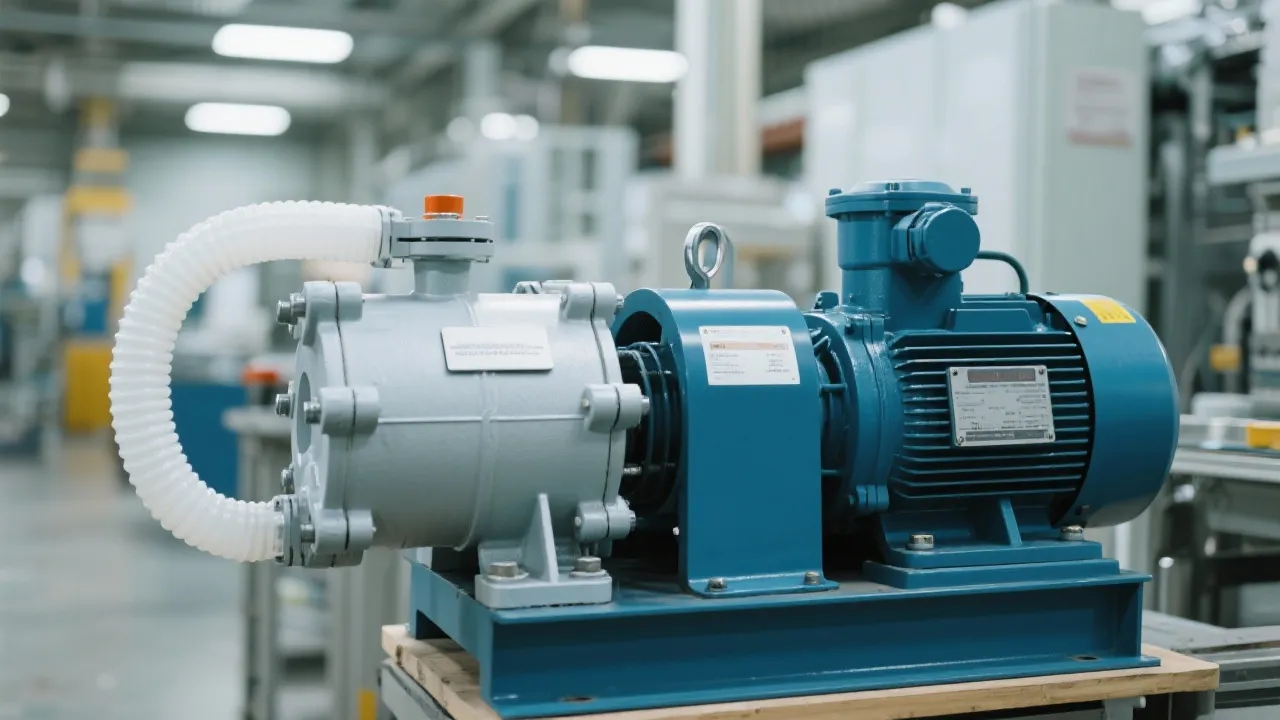

Overview of the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is engineered to deliver high performance in demanding environments. It is known for its durability and efficiency, making it suitable for sectors such as pharmaceuticals, automotive manufacturing, chemical processing, and food packaging. Users appreciate its reduced operational noise, compact design, and lower energy consumption compared to other models in its category. Moreover, the G450 exemplifies technological advancements in vacuum pump design, providing features that enhance its operational capacity while minimizing its environmental footprint. With a robust engineering foundation, it is capable of handling a wide array of applications that require consistent vacuum levels.

Features and Benefits

- High Efficiency: The Garwin G450 features advanced motor technology that ensures efficient power consumption, reducing operational costs. This efficiency translates to lower carbon emissions, contributing to more sustainable industrial practices.

- Durable Construction: Made with high-quality materials, this pump is designed to withstand the rigors of tough industrial environments. Its construction includes corrosion-resistant alloys, ensuring longevity when used in harsh chemical environments.

- Low Noise Operation: Ensures a quieter working environment, which is essential for compliance with workplace noise regulations. This feature not only benefits operators but also minimizes disturbance in sensitive environments, such as healthcare facilities.

- Compact Design: Its compact footprint allows for easy installation in spaces with limited room. This design aspect becomes crucial in industries where operational spaces are limited and equipment layout is critical to efficiency.

- Advanced Control Systems: The Garwin G450 is equipped with sophisticated control systems providing users with real-time data on pump performance. These systems allow for remote monitoring and diagnostics, enhancing overall operational oversight.

Practical Applications

The versatility of the Garwin G450 Vacuum Pump sees it deployed in various industries:

- Pharmaceuticals: Used in processes like freeze-drying and tablet coating, the Garwin G450 ensures that products maintain their integrity during manufacturing. The controlled environment created by the pump enhances the efficacy of pharmaceuticals while meeting stringent regulatory standards.

- Automotive: Essential for applications such as brake system evacuation and leak testing, its reliability ensures that automotive components function safely and efficiently. This vacuum pump is crucial in verifying the integrity of systems under production, minimizing the risk of failures post-manufacture.

- Chemical Processing: Applied in distillation processes where high vacuum conditions are necessary. This capability is vital for producing high-purity chemicals, preventing contamination and ensuring product quality.

- Food Packaging: Utilized in vacuum sealing processes that prolong shelf life and preserve quality. The ability to maintain a vacuum prevents oxidation and microbial growth, making food products safer and more appealing to consumers.

- Electronics Manufacturing: In the production of sensitive electronic components, the G450 is employed to create a controlled atmosphere that prevents moisture and other contaminants from affecting product quality. Such applications often require a delicate balance of vacuum levels and pressure to ensure that products are manufactured to precise specifications.

Specifications Overview

| Feature | Specification |

|---|---|

| Pumping Speed | 450 m³/h |

| Maximum Vacuum | 0.1 mbar |

| Power Consumption | 7.5 kW |

| Noise Level | 60 dB |

| Dimensions (L x W x H) | 900 mm x 600 mm x 700 mm |

| Weight | 150 kg |

| Operating Temperature Range | -10°C to 50°C |

Maintenance and Care

To ensure optimal performance and longevity, proper maintenance is crucial for any vacuum pump, including the Garwin G450. Regular upkeep not only prolongs the life of the equipment but also ensures safety and efficiency in operations. Below are essential maintenance practices:

- Regular Oil Checks: Maintain oil levels to ensure lubricants are effective. Low oil levels can lead to increased wear on components, decreasing efficiency.

- Filter Replacement: Periodically inspect and replace filters to prevent dust and debris from entering the pump mechanism. This step is vital in maintaining high quality in applications, particularly in cleanroom environments.

- Seal Inspection: Regularly inspect seals for wear and deteriorations. Damaged seals can lead to air leaks, which negatively impacts vacuum performance.

- Cooling System Checks: Ensure that cooling systems function correctly to prevent overheating. The G450 may incorporate cooling mechanisms that require routine checks to optimize performance.

- Performance Monitoring: Utilize the advanced control systems featured in the G450 to monitor performance parameters. Keeping track of operational metrics can alert operators to potential issues before they lead to operational failures.

FAQs

- Q: What maintenance is required for the Garwin G450 Vacuum Pump?

A: Regular maintenance includes checking oil levels, replacing filters, and inspecting for wear and tear. Operators can also take advantage of the monitoring systems in place for automated alerts regarding maintenance needs. - Q: Can the G450 be used in cleanroom environments?

A: Yes, it is designed to operate efficiently in cleanroom settings with minimal particulate emissions. The materials used in its construction are selected specifically to prevent contamination. - Q: Is the Garwin G450 compatible with corrosive substances?

A: The pump is available in models with specially coated internals to handle corrosive gases safely. These models are suitable for chemical processing industries where corrosive elements are a concern. - Q: How does the Garwin G450 perform compared to its competitors?

A: The Garwin G450 generally outperforms comparable models in terms of energy efficiency, noise levels, and overall reliability. User feedback often highlights the G450’s quieter operation and less frequent maintenance needs, contributing to its popularity. - Q: What safety features does the G450 include?

A: The G450 includes several safety features, such as over-temperature protection and a built-in emergency shut-off mechanism, which automatically disables the pump in critical situations. - Q: Can the Garwin G450 be customized for specific applications?

A: Yes, customizable options are available, allowing users to select features or configurations best suited for specific industrial requirements.

Conclusion

In summary, the Garwin G450 Vacuum Pump offers exceptional performance, making it a valuable asset across multiple industrial sectors. Its balance of efficiency, durability, and versatility ensures it meets the demanding needs of modern workflow environments. As industries continue to evolve, the need for reliable and efficient vacuum technology will grow. The Garwin G450 stands out as a model that not only meets today's challenges but is also adaptable for tomorrow's innovations.

Investing in Vacuum Technology

For businesses considering investments in vacuum technology, understanding the operational requirements and the unique advantages of each model is essential. The Garwin G450 represents a substantial commitment to reliability and efficiency, positioning it as a top choice for companies seeking to enhance their operational workflows.

Investing in high-quality equipment like the Garwin G450 can result in long-term savings, improved product quality, and increased operational safety. Companies can benefit from reduced downtime and maintenance costs while improving their productivity levels. Additionally, the environmental benefits of energy-efficient equipment promise to contribute positively to corporate sustainability initiatives.

Future Trends in Vacuum Technology

The world of vacuum technology is continuously advancing, encapsulating innovations that promise to redefine industry standards. Key trends shaping the future include:

- Energy Efficiency: With an increasing emphasis on sustainability, vacuum pumps are being designed with advanced efficiency-reduction technologies, such as variable speed drives, to minimize energy consumption.

- Smart Pump Technology: Integrating IoT (Internet of Things) technologies allows vacuum pumps to communicate performance data remotely, facilitating predictive maintenance and improving operational oversight in real-time.

- Environmental Regulations: Stricter environmental regulations are pushing manufacturers to develop greener solutions, including pumps designed to minimize emissions and employ eco-friendly materials.

- Modular and Scalable Designs: Future vacuum pumps are likely to adopt modular designs, allowing for easy upgrades or modifications to meet specific industrial needs as they arise.

Conclusion: Why Choose the Garwin G450 Vacuum Pump?

Ultimately, the Garwin G450 Vacuum Pump exemplifies how modern vacuum technology can align with the strategic objectives of industries around the world. Its robust set of features and benefits not only cover basic operational requirements but also prepare businesses for future challenges. The knowledge that they possess a reliable and efficient vacuum solution can help companies focus on their core activities and innovation, setting a foundation for future growth.

With the Garwin G450, industries can remain at the forefront of their respective markets without compromising on quality or efficiency.