Understanding the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is poised at the forefront of technological advancement in the vacuum solutions industry. Known for its reliability and efficiency, this pump is a vital component in various industrial applications, delivering consistent performance with innovative features. In this article, we delve into the distinctive attributes, operational mechanisms, and industry relevance of the Garwin G450 Vacuum Pump.

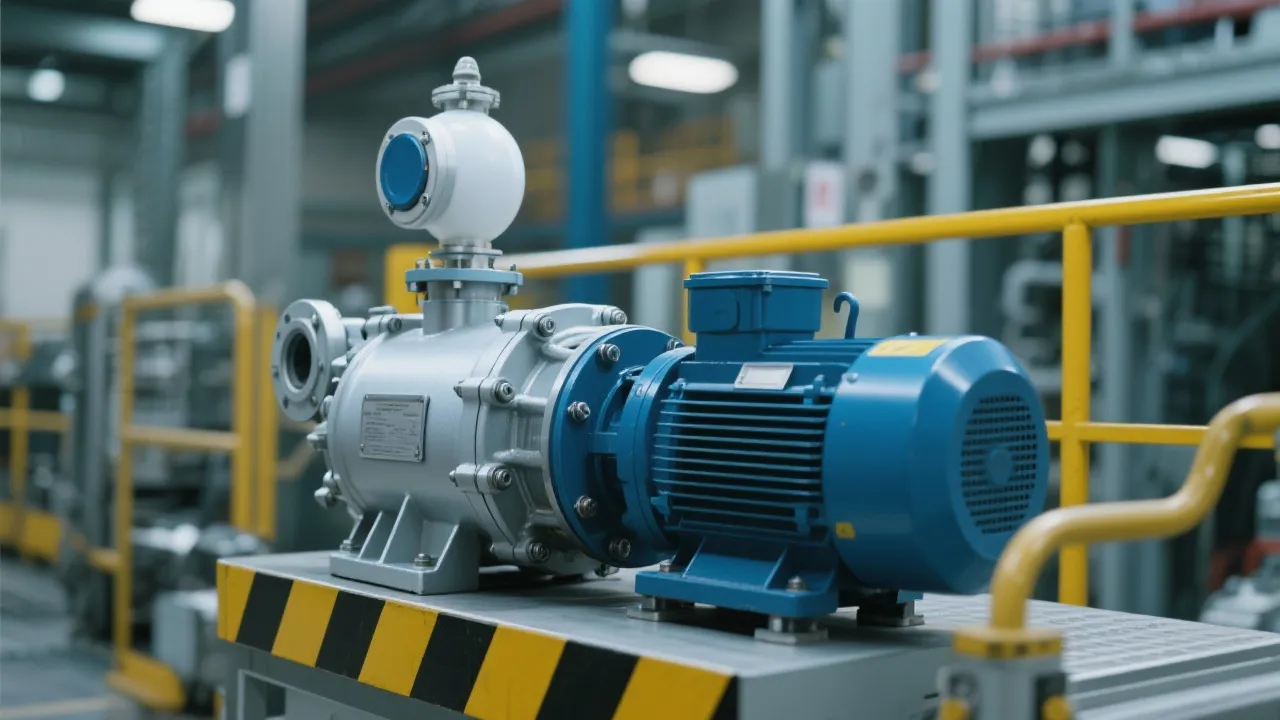

Introduction to the Garwin G450 Vacuum Pump

The industrial landscape demands high-functioning equipment that can deliver precision and efficiency, which precisely describes the Garwin G450 Vacuum Pump. As a critical tool utilized across multiple sectors, its design meets the rigorous demands of contemporary industrial environments. This article explores the features, advantages, and applications of the Garwin G450, offering an in-depth understanding for potential users and industry professionals.

Principal Features of the Garwin G450 Vacuum Pump

The Garwin G450 stands out due to its advanced features including a compact design, high suction capacity, and low noise operation. Its robust construction ensures durability and a longer service life, making it a cost-effective solution for diverse industrial applications. The pump's innovative technology also optimizes energy consumption, thus reducing operational costs for businesses. Apart from these attributes, the G450 features a user-friendly interface, which allows operators to adjust settings easily and access important operational metrics at a glance. This usability is especially beneficial in fast-paced industrial settings where time efficiency is paramount.

Operational Efficiency and Performance

Performance is key for vacuum pumps, and the G450 is equipped to handle demanding tasks with ease. Its efficiency lies in its ability to maintain consistent vacuum levels, which is crucial for processes that depend on stable atmospheric conditions. The pump's adaptability and resilience under continuous use enhance its reputation as a reliable component in production lines, laboratories, and other environments. Users often report substantial improvements in process efficiency due to the G450's ability to create and sustain the vacuum required for various applications. Furthermore, its energy-efficient design translates to significant cost savings over time, benefitting organizations that prioritize operational cost management and sustainability.

Applications in Various Industries

The versatility of the Garwin G450 Vacuum Pump allows its application in fields such as pharmaceuticals, chemical processing, and electronics manufacturing. In these sectors, its role ranges from aiding in solvent recovery and degassing operations to facilitating the packaging of sensitive electronics components. In the pharmaceutical industry, for example, the G450 is essential in processes like freeze-drying, where maintaining precise vacuum conditions is vital for product quality. Similarly, in the chemical processing sector, the pump can handle vapor extraction during distillation processes, ensuring high efficiency and safety. Its ability to adapt to both laboratory and large-scale manufacturing settings makes it a favorite among engineers and plant managers alike.

Comparison Table: Garwin G450 Vacuum Pump

| Feature | Specifications |

|---|---|

| Suction Capacity | 50 m3/h |

| Noise Level | Below 65 decibels |

| Power Consumption | 0.75 kW |

| Weight | Approx. 30 kg |

| Dimensions | 450 x 300 x 400 mm |

| Wattage | 750 W |

| Typical Vacuum Range | Up to 100 mbar |

| Operating Temperature | -10 to +40 °C |

Market Accessibility and Supplier Information

The Garwin G450 is accessible through a network of reliable suppliers who ensure that the product meets the required standards and comes with adequate customer support. This accessibility provides convenience for industries ready to integrate advanced vacuum technologies into their operations. For detailed inquiries regarding pricing and availability, consulting authorized dealers near you is advisable. In addition to physical suppliers, the Garwin G450 can also be purchased online from various industrial equipment retailers. Online platforms often provide additional resources such as customer reviews, product comparisons, and detailed specifications that assist buyers in making informed decisions.

Unique Selling Points

Among the compelling attributes of the Garwin G450 are its user-friendly maintenance protocols and digital interface that facilitates easy monitoring and control. These aspects, combined with the provision of comprehensive customer service, heighten the overall value proposition of this vacuum pump. The digital interface not only displays operational metrics but also provides alerts for maintenance needs, minimizing downtime and allowing for proactive management of equipment health. Furthermore, the G450’s design considers environmental factors, offering a low-emission operation that aligns with global sustainability initiatives. This is an essential characteristic for companies looking to reduce their carbon footprint while maintaining efficiency.

FAQs

- What maintenance is required for the Garwin G450 Vacuum Pump?

The G450 requires periodic checks and oil changes based on operational hours to ensure optimal performance. Users are also advised to inspect the inlet filter regularly and replace it as needed to prevent particulate contamination from affecting pump efficiency. - Can the Garwin G450 handle continuous operation?

Yes, the design of the G450 is robust and suitable for continuous, 24/7 operation, which is paramount for industries that rely on uninterrupted production cycles. Ventilation around the pump should be ensured to avoid overheating during extended use. - Is the Garwin G450 suitable for cleanroom environments?

Absolutely, its low noise and emission characteristics make it ideal for cleanrooms. The pump’s design minimizes the release of particulates and contaminants, ensuring compliance with strict cleanliness standards often required in pharmaceutical and semiconductor industries. - What is the warranty period for the Garwin G450?

The G450 typically comes with a standard warranty that covers manufacturing defects. Be sure to check with your supplier for specific details regarding warranty length and coverage. - Can the G450 be integrated into automated systems?

Yes, the G450 can be integrated into automated systems through its digital interface, which allows for easy data exchange and process control, making it suitable for industries employing Industry 4.0 practices. - What is the average lifespan of the Garwin G450 Vacuum Pump?

With proper maintenance, the Garwin G450 can have a lifespan of several years. Regular maintenance, proper use, and adherence to recommended operational parameters play key roles in extending the pump’s life span.

User Testimonials

Real-world feedback from industry professionals further validates the effectiveness and reliability of the Garwin G450 Vacuum Pump. Users across various sectors have praised its performance particularly in environments where high precision is required. For instance, a laboratory manager in the biotech sector noted how the G450 improved their vacuum processes during sample preparation, leading to improved yields in their experiments. Efforts were subsequently increased towards the optimization of ongoing research as the pump provided consistent and reliable vacuum levels.

Similarly, a production supervisor in an electronics manufacturing plant reported significant improvements in the packaging process after integrating the G450 into their operations. The vacuum levels achieved by the pump allowed for better sealing of products, reducing defects and enhancing overall product integrity, leading to higher customer satisfaction rates.

Technical Support and Resources

To ensure users can fully optimize their usage of the Garwin G450 Vacuum Pump, manufacturers often provide extensive technical support and resources. These resources include detailed user manuals, maintenance guides, and access to customer service representatives who are knowledgeable and equipped to troubleshoot common issues. Online forums and user communities dedicated to the G450 allow users to share experiences and solutions, creating a platform for collective problem-solving. Additionally, workshops and training sessions may be offered by suppliers or manufacturers to help personnel better understand the operational nuances of the G450, maximizing efficiency and productivity.

Conclusion

The Garwin G450 Vacuum Pump is emblematic of the synergy between technology and industrial needs. As sectors continue to evolve, dependable tools like the G450 will be indispensable in driving efficiency and innovation. As industries are increasingly challenged to enhance productivity while managing cost and compliance, the G450 offers a balanced solution that meets these demands. Businesses looking to invest in vacuum technology would find that integrating the Garwin G450 not only fortifies their operational framework but positions them competitively in their respective markets.

With its numerous benefits, from reduced energy consumption to its robust durability, the Garwin G450 Vacuum Pump stands as a testament to modern engineering and provides a pivotal role in enhancing productivity across multiple sectors. Future advancements and innovation in vacuum technology may further solidify the standing of the Garwin G450 as a leading choice for industrial applications.