Understanding the Garwin G450 Vacuum Pump

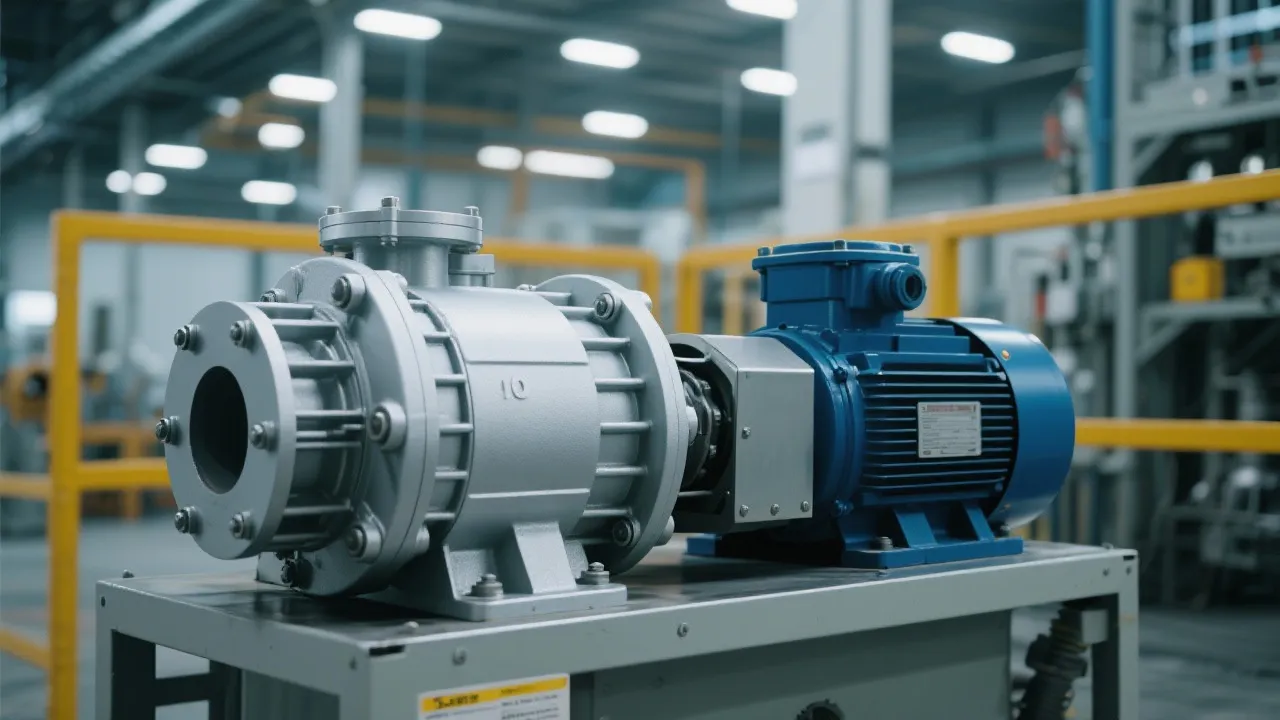

The Garwin G450 Vacuum Pump stands as a critical component in industrial applications, offering efficiency and reliability. This article delves into its significance, operational mechanisms, and potential uses across various industries. We explore the pump's features, advantages, and performance metrics, alongside providing insights from industry professionals and addressing common inquiries regarding maintenance and optimization.

Introduction to Vacuum Technologies

In the realm of industrial and scientific applications, vacuum pumps serve as fundamental tools, allowing processes to occur under controlled pressure environments. Among these indispensable devices, the Garwin G450 Vacuum Pump emerges as a top choice for achieving optimal efficiency and reliability in diverse settings. Vacuum technology is not merely about creating low-pressure environments; it plays a vital role in various applications, including material processing, food packaging, and chemical engineering. The ability to manipulate pressure effectively allows industries to innovate and perfect their processes, resulting in improved product quality and operational efficiency.

Significance of the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is renowned for its capacity to handle rigorous tasks across numerous industries, from electronics manufacturing to laboratories requiring precise atmospheric conditions. Its design emphasizes both robustness and ease of maintenance, making it a trusted option for professionals who demand high performance and durability. The significance of the G450 also extends beyond its technical features; it embodies the need for reliability and efficiency in environments where every second and every micrometer counts. For instance, in the pharmaceutical industry, a slight deviation in vacuum pressure can affect the results of experiments, making the use of a trustworthy vacuum pump like the G450 indispensable.

Technical Features and Advantages

The G450 model is engineered with advanced technologies that provide it with superior capability to manage vacuum pressure with remarkable precision. Key features include an oil-sealed mechanism, which enhances the longevity of the pump while ensuring minimal operational noise. The oil-sealed system also inherently reduces the risk of contamination, a vital aspect in cleanroom applications where even the slightest particles can compromise product integrity. Furthermore, this model often garners praise for its energy efficiency, reducing the cost of operation over time. The ability to operate with minimal energy consumption not only benefits the user’s finances but also contributes to environmental sustainability—an increasingly critical aspect in today’s industrial practices.

Performance and Applications

When evaluating the pump's performance, experts highlight its ability to maintain consistent vacuum levels even under continuous use. This reliability makes it ideal for applications in sectors such as pharmaceuticals, where consistency in pressurized environments is crucial. Additionally, the equipment's versatility allows it to be adapted in various vacuum forming and coating tasks requiring precise atmospheric conditions. Beyond these sectors, the Garwin G450 also finds application in the electronics field, where it is used in the assembly of components that require low-pressure systems to prevent oxidation and other undesirable reactions. The automotive industry, particularly in the production of tires and other rubber products, also leverages vacuum technology for superior quality assurance. The consistent atmospheric conditions enabled by the G450 lead to reduced product defects and enhanced production speeds, illustrating its multifaceted utility.

| Feature | Advantage |

|---|---|

| Oil-Sealed Mechanism | Ensures longevity and quiet operation |

| Energy Efficiency | Reduces overall operational costs |

| Robust Design | Handles rigorous industrial applications |

| Compact Footprint | Ideal for space-constrained environments |

| Adjustable Vacuum Levels | Offers flexibility for various applications |

Expert Insights on Maintenance

To ensure the longevity and peak performance of the Garwin G450 Vacuum Pump, regular maintenance is advised. Industry experts suggest a structured maintenance schedule that includes periodic inspection of seals and oil levels, ensuring that the pump operates without undue wear and tear. Such proactive measures not only extend the pump's lifespan but also optimize its efficiency in demanding settings. Moreover, a detailed record-keeping of maintenance activities can help in identifying trends that might signal the need for more extensive repairs or replacements in the future. Understanding the signs of wear, such as increased noise or fluctuating pressure readings, can empower operators to address issues before they escalate into significant problems.

Garwin G450 Vacuum Pump FAQs

- What industries benefit very from the Garwin G450?

The pump finds its utility in electronics, pharmaceuticals, coatings, and scientific research due to its robust design and precision control. - How does the oil-sealed mechanism improve performance?

It ensures the pump runs quietly and efficiently, reducing friction-related wear and prolonging operational life. - What are the maintenance requirements?

Regular checks on oil levels and seal conditions, along with routine cleaning, ensure optimal performance. - Can the Garwin G450 handle harsh environments?

This vacuum pump is designed to operate effectively in demanding industrial environments, with durable components that resist wear and corrosion. - What is the expected lifespan of the Garwin G450?

While the lifespan may vary based on usage and maintenance, many operators report optimal performance for several years with proper care.

Conclusion

The Garwin G450 Vacuum Pump offers an exemplary combination of efficiency, reliability, and adaptability, making it an invaluable asset in both industrial and research settings. Understanding its operational features and advantages equips users with the knowledge to maximize the pump's capabilities while ensuring its good functionality. Beyond the mechanical aspects, the integration of vacuum technology into various industries illustrates the ongoing evolution of manufacturing processes and the pursuit of excellence in product quality and reliability.

Future Trends in Vacuum Technology

As technology progresses, vacuum systems are evolving to meet new challenges and demands. One significant trend is the development of smart vacuum pumps, which leverage IoT (Internet of Things) technologies to provide data-driven insights on performance metrics such as pressure levels, energy consumption, and maintenance schedules. These pumps can enable predictive maintenance, significantly reducing downtime and improving operational efficiency. Additionally, advancements in materials science are leading to the creation of more durable components that can withstand greater pressures and temperatures, further extending the capabilities of vacuum pumps like the Garwin G450.

Vacuum Technology in Research and Development

In research environments, vacuum technology plays a pivotal role in a variety of experimental processes. When working with sensitive materials that can degrade or react with air, such as certain polymers or chemicals, maintaining a vacuum is essential for safeguarding the integrity of the experiments. For example, in materials science, vacuum chambers are often used to create and manipulate thin films or coatings. The precise control over the atmospheric conditions allows researchers to explore new material properties and behaviors that could be pivotal for advancements in technology. The use of the Garwin G450 can facilitate this research by providing a stable and reliable vacuum, crucial for achieving reproducible results.

Environmental Considerations

The operation of vacuum pumps can sometimes lead to environmental concerns, particularly in regard to their energy consumption and potential emissions. Manufacturers are increasingly being held accountable for the environmental footprint of their products, and innovations aimed at reducing energy use are becoming paramount. The Garwin G450, with its energy-efficient design, can be seen as a response to these concerns, as it minimizes energy consumption while still delivering exceptional performance. Additionally, advancements in fume and contaminant filtration technologies are enhancing the environmental friendliness of vacuum operations by efficiently capturing and neutralizing emissions before they can affect the environment.

Comparative Analysis with Other Pump Models

When considering vacuum pumps, it is essential to compare the Garwin G450 with other models on the market. Competing models may offer various features, and a detailed analysis can aid in selecting the most suitable option for specific applications. For instance, while some pumps might have lower initial costs, the Garwin G450 may outshine these alternatives in terms of durability and longevity, leading to lower total ownership costs. Furthermore, while certain models may optimize for higher vacuum levels, they might sacrifice operational noise levels or energy efficiency. Understanding these trade-offs allows users to make informed decisions that align with their operational demands.

The Role of Training and Education

In a high-tech industrial environment, training and educating staff on vacuum technology, particularly regarding efficient operation and maintenance of pumps like the Garwin G450, are critical. Comprehensive training programs can empower employees with the knowledge to recognize potential issues before they affect operations, leading to reduced downtime and safer working conditions. Organizations that invest in training not only enhance employee satisfaction and efficiency but also ensure that all personnel can operate equipment to its fullest potential, leading to improved product quality and operational excellence.

The Future of Vacuum Pumps in Industrial Applications

The future of vacuum pumps in industrial applications seems to be leaning towards increased automation and integration with other manufacturing processes. As industries seek to create more streamlined and efficient workflows, vacuum systems must adapt by integrating with systems like robotics, automated quality control, and advanced monitoring technologies. These integrations can lead to smarter, more responsive production environments that maximize output while minimizing waste. As such, the Garwin G450 and similar models will likely evolve, not only to meet current demands but to anticipate the changing landscape of manufacturing and industrial processes.

Conclusion and Final Thoughts

The Garwin G450 Vacuum Pump stands as a testament to the advancements in vacuum technology that have significantly impacted various industries. With its superior engineering, reliability, and adaptability, this pump is set to play a pivotal role in future innovations. The continued focus on efficiency, environmental impact, and integration with other technologies will shape the evolution of vacuum applications in the coming years. For industries aiming to stay at the forefront of technological advancements, investing in high-quality vacuum systems like the Garwin G450 is not just beneficial but essential for sustaining competitive advantage in a rapidly changing marketplace.