Understanding the Garwin G450 Vacuum Pump

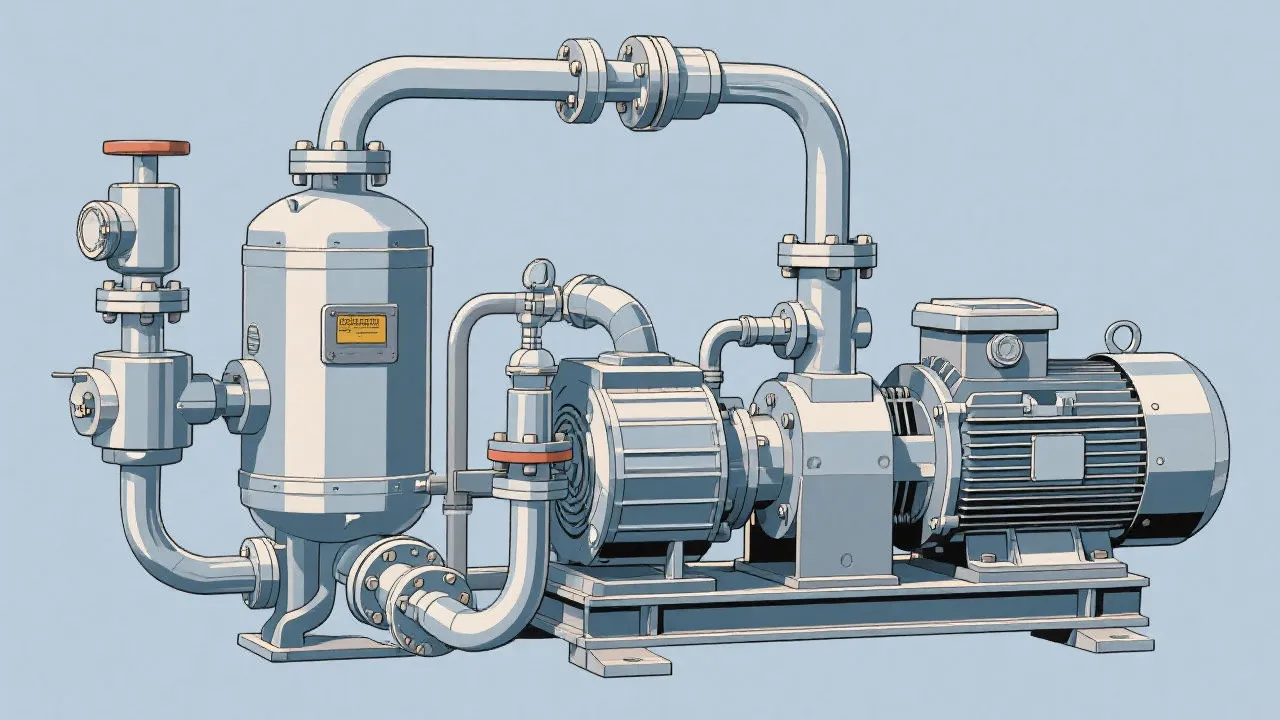

The Garwin G450 Vacuum Pump is a cutting-edge industrial device engineered for seamless operation in diverse environments. This state-of-the-art apparatus facilitates efficient gas removal, optimizing processes ranging from manufacturing to scientific applications. Leveraging advanced technologies, the G450 enhances productivity through its reliable performance, energy efficiency, and robust design.

The Garwin G450 Vacuum Pump: An Overview

The Garwin G450 Vacuum Pump stands as a leading solution in the realm of industrial machinery, offering unparalleled efficiency and reliability. In various industries, the necessity to create a controlled atmosphere, free from unwanted gases and vapors, is paramount. The G450, with its innovative design, fulfills this need by enabling high-speed gas removal without compromising on energy consumption. It's tailored to meet the rigorous demands of sectors such as manufacturing, pharmaceuticals, and research laboratories, making it a versatile addition to any professional setting.

Moreover, its adaptability allows it to cater to a range of applications, from large-scale industrial operations to smaller, specialized tasks. This flexibility has made it a preferred choice among operators looking for manageable systems that do not sacrifice performance. As we delve deeper into its specifications and uses, it becomes clear that the Garwin G450 is not just a tool but a significant contributor to process optimization across diverse industries.

Technical Specifications and Features

Delving into the technical specifics of the Garwin G450 reveals its robust capabilities. This vacuum pump encompasses advanced materials that enhance its durability and resistance to wear. Key features include a state-of-the-art rotor design, which minimizes friction and heat production, thereby prolonging the pump's lifespan. Additionally, its user-friendly interface allows easy operation and maintenance, catering to both novice and expert users.

Beyond its essential features, the design of the G450 incorporates several cutting-edge technologies that further ensure efficiency and functionality. For instance, the materials used for construction not only withstand high-stress operations but are also corrosion-resistant, which extends the lifespan of the pump in challenging environments. The G450 integrates intelligent control systems that monitor performance in real-time, allowing for adjustments that optimize output based on specific operational needs.

| Feature | Description |

|---|---|

| Advanced Rotor Design | Minimizes friction, reducing heat and wear for a longer lifespan. |

| Energy Efficiency | Optimized for low energy consumption without sacrificing performance. |

| User-Friendly Interface | Enables easy operation, suitable for both novices and professionals. |

| Corrosion Resistance | Constructed with materials that endure harsh environments and extend operational life. |

| Intelligent Control Systems | Real-time performance monitoring and adjustments to optimize vacuum output. |

| Compact Design | Space-saving footprint, making it suitable for various setups with limited space. |

Application Scenarios for the Garwin G450

The versatility of the Garwin G450 Vacuum Pump allows it to be deployed across a wide array of industries. In the manufacturing sector, it plays a crucial role in processes that require precise control of atmospheric conditions, such as the production of semiconductors or the drying of electronic components. The accuracy of vacuum levels achieved by the G450 ensures that defects due to air entrapment or contamination are minimized, facilitating a more reliable manufacturing process.

In pharmaceuticals, the pump ensures the removal of contaminants, maintaining the integrity of sensitive compounds. This is especially critical during the formulation of medications where active ingredients must remain pure. The Garwin G450 also supports processes like freeze-drying, where maintaining a stable vacuum is essential for producing high-quality products. By managing moisture levels precisely, it contributes to the overall efficacy and shelf life of pharmaceuticals.

Research laboratories benefit from its ability to create vacuum conditions required for various experimental setups. From promoting chemical reactions to managing distillation processes, the G450's capabilities support a wide range of scientific inquiries. Moreover, its adaptability means that it can be easily incorporated into existing setups, making it a favorite among researchers who require both reliability and performance without any major system overhauls.

Additionally, industries like food processing and packaging have discovered the advantages of utilizing the Garwin G450. In food packaging, the vacuum pump is instrumental in extending the shelf life of products by removing air and thus inhibiting the growth of bacteria and molds. Such practical applications illustrate the breadth of the G450’s usage, emphasizing its role in ensuring safe and efficient operations across multiple sectors.

FAQ and Industry Insights

What industries benefit the most from the Garwin G450? Industries that require precise environmental control, such as manufacturing, pharmaceuticals, research, food processing, and electronics manufacturing, find the G450 particularly advantageous. The vacuum pump's versatility ensures it can excel in varied applications, reinforcing its value in both specialized and broader industrial contexts.

How does the G450 enhance energy efficiency? Its advanced engineering minimizes energy use by reducing mechanical friction and optimizing air displacement. The integration of intelligent controls allows for tailored performance that matches operational demands, meaning less energy is wasted during low-demand scenarios. This not only lowers operational costs but also reduces the environmental footprint of manufacturing processes.

Can the pump be used in small-scale operations? Yes, its versatile design makes it suitable for both large-scale industrial applications and smaller, specialized operations. The G450's compact design allows it to fit into environments where space is a concern while maintaining robust performance across various applications.

How does the Garwin G450 contribute to research development? In research environments, the G450 aids in creating controlled conditions that are crucial for experiment repeatability and accuracy. Its advanced pumping capabilities support a range of applications, from material synthesis to biological studies, ensuring researchers can achieve their objectives with precision and reliability.

Conclusion

The Garwin G450 Vacuum Pump exemplifies the fusion of technology and practicality, providing an efficient solution for industrial applications where air purity and energy efficiency are of utmost importance. Its cutting-edge features, coupled with a robust and reliable design, make it an invaluable asset to industries aiming to enhance production while minimizing operational costs. The G450 not only meets the immediate needs of its users but also adapts to the evolving demands of the industry.

The ongoing advancements in vacuum technology echo the importance of choosing the right equipment, and the Garwin G450 stands out as a leader in this domain. As industries continue to innovate and demand more from their equipment, the adaptability and efficiency of the G450 ensure that it will remain a top choice for businesses looking to maintain a competitive edge. With the ability to combine efficiency and versatility, this vacuum pump supports the next generation of processes, paving the way for advancements across multiple fields.

Furthermore, the Garwin team is committed to ongoing research and development, ensuring that the G450 not only meets current industry standards but also anticipates future needs. As sustainability becomes an ever-more pressing concern, the energy-saving features of the G450 signal a commitment to eco-friendly practices within industrial applications. This proactive approach in product design and functionality positions the Garwin G450 not just as a piece of equipment, but as a partner in the journey towards better operational efficiency and sustainability.

Overall, the Garwin G450 is more than a vacuum pump; it is a critical component in the broader framework of industrial excellence. By fostering an environment where innovation can thrive, the G450 empowers businesses across diverse sectors, exemplifying how high-performance machinery can be both effective and responsible in today's global market.