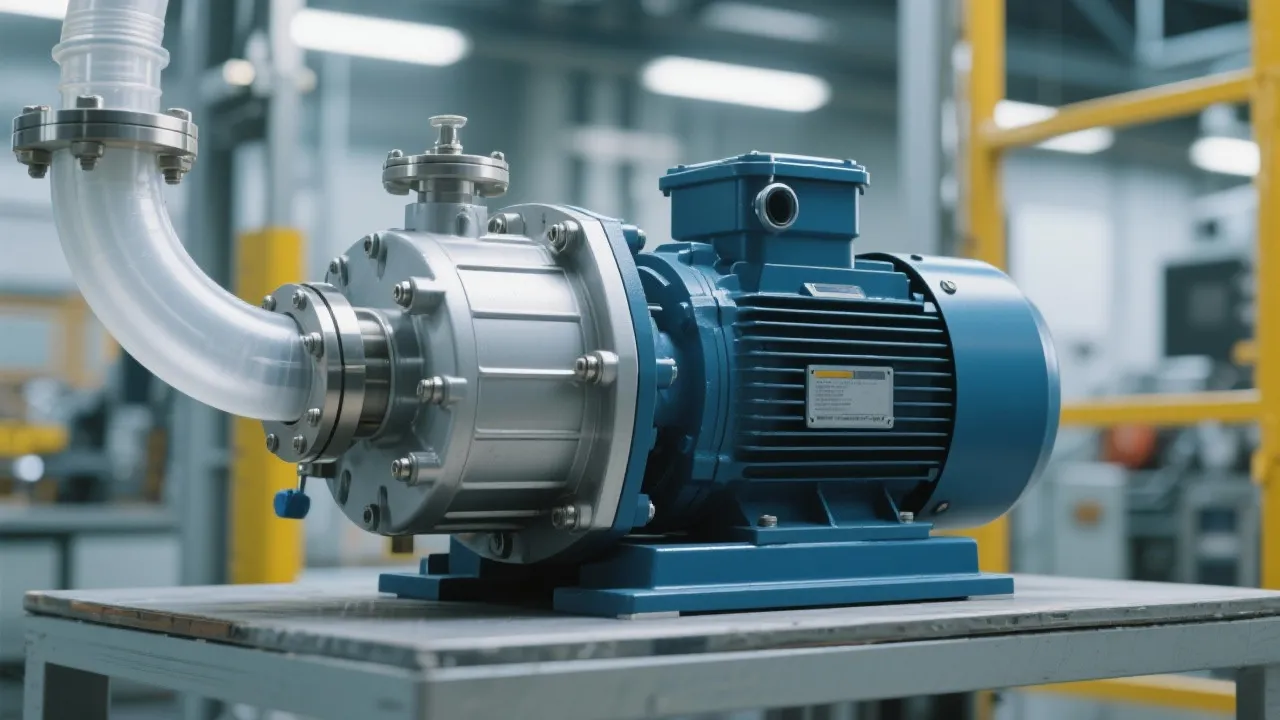

Unveiling the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump stands out as a premier choice in the realm of industrial vacuum solutions, praised for its reliability and efficiency. Known for its robust construction and excellent performance, the G450 is indispensable for heavy-duty applications requiring consistent vacuum pressure. This article explores the features, benefits, and use cases of the Garwin G450 Vacuum Pump, offering a detailed industry analysis.

Introduction to the Garwin G450 Vacuum Pump

The Garwin G450 Vacuum Pump is a hallmark of engineering excellence, designed specifically for industries demanding robust and efficient vacuum solutions. Known for its high performance, the G450 model has set a benchmark in the vacuum technology market, providing users with a substantial edge in terms of reliability and operational excellence. This article delves into the aspects that make the Garwin G450 Vacuum Pump a favored choice for industrial applications. With a blend of innovative technology and user-friendly design, the G450 stands as a vital component in various production environments.

Engineering Excellence and Design

The Garwin G450 is engineered to offer reliable performance, characterized by a rugged design that ensures longevity even under demanding operational conditions. Incorporated with advanced technological features, the G450 provides a seamless experience, reducing downtime and maintenance costs. Its design supports a wide range of applications, from manufacturing to research laboratories, highlighting its versatility and adaptability. The materials used in the construction of the G450 are selected based on their durability, heat resistance, and compatibility with various industrial settings. This careful consideration ensures that the pump can operate effectively in diverse environmental conditions, including extreme temperatures and fluctuating atmospheric pressures.

Moreover, the G450's compact design enables it to be installed in tight spaces without compromising performance. This is especially beneficial in urban settings where space is often at a premium. The modularity of the vacuum pump, allowing for easy integration with other systems and machinery, enhances its appeal across various industries. Additionally, the pump's lightweight nature helps facilitate easier transport and installation, making it accessible for a wider range of applications.

Key Features of the Garwin G450 Vacuum Pump

Users appreciate several standout features of the Garwin G450 Vacuum Pump:

- High Efficiency: It boasts impressive energy efficiency, translating into lower operational costs and reduced environmental impact. The innovative motor technology ensures that energy consumption is minimized during operation without sacrificing performance. Users can expect significant savings on energy bills over the lifetime of the pump.

- Sturdy Construction: Built to last, the pump's durable construction minimizes wear and tear, enhancing its lifespan. The components are designed with corrosion-resistant materials that withstand aggressive substances often found in chemical processing or food production environments, prolonging the pump's usability.

- Ease of Maintenance: Designed for minimal maintenance, it ensures prolonged operational uptime, ideal for continuous industrial operations. It features self-diagnostic capabilities, allowing for proactive troubleshooting without needing extensive technician involvement.

- Low Noise Operation: The G450 operates with reduced noise levels compared to its competitors, making it suitable for environments where noise pollution is a concern, such as laboratories and research facilities.

- Smart Technology Integration: The pump is equipped with smart technology that allows for real-time monitoring and optimization of performance parameters. This feature is particularly advantageous in settings requiring strict adherence to specifications and operational standards.

Applications and Use Cases

The versatility of the Garwin G450 Vacuum Pump renders it suitable for various applications including:

- Pharmaceutical Manufacturing: Utilized for maintaining sterile conditions crucial for drug production. The G450 ensures that the vacuum levels remain constant, minimizing contamination risk during the packaging of drugs and medical devices.

- Food Processing Industries: Ensures an oxygen-affordable environment essential for certain food preservation processes. Vacuum packaging, modified atmosphere packaging, and freeze-drying applications all benefit from the reliable performance of the G450.

- Electronics Manufacturing: Provides the precise vacuum conditions necessary for semiconductor fabrication. In this industry, even minute deviations in vacuum levels can result in defective products, making the accuracy of the G450 critical.

- Aerospace Engineering: The G450 is employed in various processes including composite material production and in vacuum casting techniques for creating parts that meet stringent aerospace standards.

- Research Laboratories: Various scientific research facilities utilize the G450 for processes involving vacuum distillation, extraction, and concentration of samples, where maintaining an uncontaminated environment is paramount.

- Automotive Industries: Employed in the testing of automotive components for leaks, the G450 ensures that the components are thoroughly tested under vacuum conditions.

Comparative Analysis

| Feature | Garwin G450 | Competitor A | Competitor B |

|---|---|---|---|

| Energy Efficiency | High | Moderate | Low |

| Maintenance Requirements | Low | High | Moderate |

| Durability | High | Moderate | High |

| Noise Level | Low | Moderate | High |

| Smart Technology Features | Yes | No | Yes |

Benefits of Choosing the Garwin G450

Opting for the Garwin G450 Vacuum Pump brings numerous advantages, such as reducing operational interruptions and providing a streamlined workflow. Its consistent performance metrics ensure that industries relying on vacuum technology maintain their production quality and efficiency. The high energy efficiency and low maintenance requirements lead to significant cost savings over the unit's lifespan, which is an essential consideration for any production facility.

Furthermore, the G450's robust build translates into decreased risk of operational failures that can lead to costly downtime, protecting the investment made by the user. The ability to work effectively in various industries also creates an opportunity for facilities to consolidate multiple vacuum systems into a single versatile solution, again saving on costs associated with maintenance, training, and equipment purchase. The smart technology incorporated into the G450 enhances user experience, enabling better decision-making and process management through monitoring and diagnostics.

The seamless integration of the Garwin G450 into existing production lines facilitates minimal disruption during installation. Users have reported that bringing the G450 online is often quicker and simpler compared to other systems, allowing companies to maintain tight production schedules. As demands for faster production turnover grow, equipment that allows for such flexibility becomes invaluable.

FAQs

Q: What industries benefit the very from the Garwin G450 Vacuum Pump?

A: Industries such as pharmaceuticals, food processing, electronics manufacturing, aerospace engineering, research laboratories, and automotive sectors find the G450 particularly beneficial due to its robust and efficient performance.

Q: How does the Garwin G450 compare in terms of power usage?

A: It is designed to be one of the very energy-efficient pumps in its category, helping reduce electricity costs while maintaining output. Many facilities report significant declines in their energy bills upon switching to the G450.

Q: Is the Garwin G450 easy to install?

A: Yes, it features a user-friendly design that simplifies installation, making it accessible for both small enterprises and large-scale operations. The straightforward user manual and the support of Garwin’s customer service team further enhance the installation process.

Q: What is the expected lifespan of the Garwin G450 Vacuum Pump?

A: With proper maintenance, the G450 can last significantly longer than many comparable models. Users can expect an operational lifespan of over ten years, depending on the working conditions and frequency of use.

Q: Can the G450 be integrated with existing systems?

A: Absolutely! The G450 has been designed with modularity and compatibility in mind, allowing it to fit seamlessly into existing vacuum systems and workflows, enhancing operational flexibility.

Testimonials from Users

Industrial feedback on the Garwin G450 Vacuum Pump has generally been positive, with many users highlighting its reliability and efficiency. For instance, a pharmaceutical company reported a notable decrease in contamination incidents since implementing the G450 in their production line. They cited that the pump's advanced filtration system and active monitoring helped maintain the necessary sterile conditions throughout their manufacturing processes.

Similarly, a food processing facility noted the energy savings achieved through its use. They emphasized that the enhanced energy efficiency of the Garwin G450 did not only contribute to reduced operational costs but also aligned with their sustainability goals, showcasing their commitment to responsible environmental practices.

Another user in the electronics manufacturing sector praised the pump's performance in maintaining consistently low vacuum levels during sensitive processes. They mentioned that the G450's accurate monitoring technology allowed them to catch potential issues before they affected production, enhancing their overall quality control processes.

Future Outlook and Technological Advances

The future of vacuum technology is continually evolving, with significant advancements anticipated in areas such as automation and smart technology integration. The Garwin G450 Vacuum Pump positions itself at the forefront of these changes. As industries transition to more automated processes, the demand for vacuum systems that can seamlessly integrate with automated workflows will grow. The G450's smart technology features will likely become increasingly relevant as more facilities seek solutions that offer real-time data analytics and remote monitoring capabilities.

These technological advancements will enhance the pump's capabilities, allowing users to adjust performance settings remotely according to operational demands. Additionally, innovations in materials science may pave the way for even more durable components, reducing wear and tear and extending the pump's lifetime even further.

Furthermore, sustainability will continue to shape the vacuum industry. Regulatory pressures pushing for greener manufacturing practices will further drive the development of energy-efficient solutions. As the Garwin G450 consistently proves its efficiency, it will likely adapt to these evolving needs, ensuring it remains a leader in the vacuum technology market.

Conclusion

The Garwin G450 Vacuum Pump represents a significant advancement in the vacuum technology sector, offering unparalleled reliability and efficiency. Its well-rounded features make it a top choice for industries seeking to enhance their operational capabilities. As industrial demands continue to rise, the G450 stands ready to meet these challenges with exceptional performance and durability. With a future focused on integration and sustainability, the Garwin G450 is not just a solution for today’s vacuum needs but is poised to adapt and evolve as technologies progress, ensuring it remains a relevant tool in the industrial landscape for years to come.

In summary, when investing in vacuum technology, the Garwin G450 stands out due to its energy efficiency, low maintenance requirements, and robust construction. Its wide range of applications and satisfied customer testimonials reinforce its status as a leading choice for industries that rely on precise and reliable vacuum solutions. Whether in pharmaceuticals, food processing, electronics manufacturing, or beyond, the impact of the Garwin G450 Vacuum Pump on operational excellence and efficiency is undeniable.